Abstract

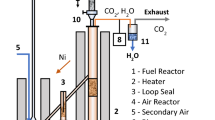

We developed a mathematical model to discuss the performance of chemical looping combustion (CLC) of methane in continuous bubbling fluidized-beds. The model considers the particle population balance, oxidation and reduction rate of particles in fluidized beds. It also considers utilization efficiency of oxygen carrier (OC) particles, residence time of particles in each reactor, and particle size in reaction rate. The model was applied for a bubbling coreannulus fluidized-bed process. The core bed was the fuel reactor (0.08 m-i.d., 2.1 m-height) and the annulus bed was the air reactor (0.089 m-i.d., 0.15 m-o.d., 1.6 m-height). The process employed a type of Ni-based OC particles. The present model agrees reasonably well with the combustion efficiency measured in the process. Simulation was performed to investigate the effects of some variables for the process. The present model revealed that the range of circulation rate of OC particles for achieving complete combustion determined the operating range of the CLC system. The minimum circulation rate of OC particles for complete combustion decreased in the considered operating range as temperature or bed mass increased in the fuel reactor. A large mass of the fuel bed was necessary to obtain complete combustion at low fuel reactor temperature. The fresh feed rate of OC particles for steady state operation increased in complete combustion condition as temperature or static bed height or gas velocity increased.

Similar content being viewed by others

References

S. Balaji, J. Ilic, B. E. Ydstie and B. H. Krogh, Ind. Eng. Chem. Res., 49, 4566 (2010).

Z. Deng, R. Xiao, B. Jin, Q. Song and H. Huang, Chem. Eng. Technol., 31, 1754 (2008).

J. Jung and I. K. Gamwo, Powder Technol., 183, 401 (2008).

A. Abad, J. Adanez, F. Garcia-Labiano, L. F. de Diego and P. Gayan, Energy Procedia, 1, 391 (2009).

A. Abad, J. Adanez, F. Garcia-Labiano, L. F. de Diego and P. Gayan, Combust. Flame, 157, 602 (2010).

J. Bolhàr-Nordenkampf, T. Proell, P. Kolbitsch and H. Hofbauer, Chem. Eng. Technol., 32, 410 (2009).

Z. Deng, R. Xiao, B. Jin and Q. Song, Int. J. Greenhouse Gas Control, 3, 368 (2009).

P. Kolbitsch, T. Proell and H. Hofbauer, Chem. Eng. Sci., 64, 99 (2009).

I. Iliuta, R. Tahoces, G. S. Patience, S. Rifflart and F. Luck, AIChE J., 56, 1063 (2010).

H. Kruggel-Emden, S. Rickelt, F. Stepanek and A. Munjiza, Chem. Eng. Sci., 65, 4732 (2010).

C. E. Lapple, Chem. Eng., 58, 144 (1951).

D. Kunii and O. Levenspiel, Fluidization engineering, 2nd Eds., Butterworth-Heinemann, Boston, U.S.A. (1991).

J. H. Choi, C. K. Yi and S. H. Jo, Korean J. Chem. Eng., 28, 1144 (2011).

D. Merrick and J. Highley, AIChE Symp. Ser., 70, 366 (1974).

J. Werther and J. Reppenhagen, AIChE J., 45, 2001 (1999).

C. Y. Wen and Y. H. Yu, AIChE J., 12, 610 (1966).

H.-J. Ryu, P. S. Yoon and J.-H. Choi, in Abstracts for 2010 Korea institute of chemical engineering fall meeting, 275 (2010).

Y.-W. Jeon, Hydrodynamic and oxidation-reduction reaction characteristics of oxygen carrier particles in an annular type chemical looping combustor, Master Thesis, Korea Advanced Institute of Science and Technology, Daejeon, Korea (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, JH., Youn, P.S., Brahimi, D. et al. A model on chemical looping combustion of methane in a bubbling fluidized-bed process. Korean J. Chem. Eng. 29, 737–742 (2012). https://doi.org/10.1007/s11814-011-0238-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-011-0238-7