Abstract

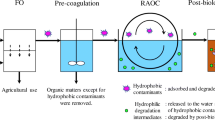

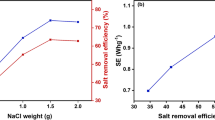

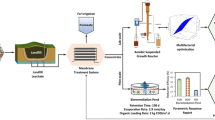

Reverse osmosis (RO) is frequently used forwaterreclamation fromtreated wastewaterordesalination plants. The RO concentrate (ROC) produced from the coal chemical industry (CCI) generally contains refractory organic pollutants and extremely high-concentration inorganic salts with a dissolved solids content of more than 20 g/L contributed by inorganic ions, such as Na+,Ca2+,Mg2+,Cl−, and SO42−. To address this issue, in this study, we focused on coupling forward osmosis (FO) with chemical softening (FO-CS) for the volume minimization of CCI ROC and the recovery of valuable resources in the form of CaCO3. In the case of the real raw CCI ROC, softenin2g trea2tment by lime-soda ash was shown to effectively remove Ca2+/Ba2+ (>98.5%) and Mg2+/Sr2+/Si (>80%), as well as significantly mitigate membrane scaling during FO. The softened ROC and raw ROC corresponded to a maximum water recovery of 86% and 54%, respectively. During cyclic FO tests (4 × 10 h), a 27% decline in the water flux was observed for raw ROC, whereas only 4% was observed for softened ROC. The cleaning efficiency using EDTA was also found to be considerably higher for softened ROC (88.5%) than that for raw ROC (49.0%). In additio3 CaCO3 (92.2% purity) was recovered from the softening sludge with an average yield of 5.6 kg/m3 treated ROC. This study provides a proof-of-concept demonstration of the FO-CS coupling process for ROC volume minimization and valuable resources recovery, which makes the treatment of CCI ROC more efficient and more economical.

Similar content being viewed by others

References

Cornwell D A, Davis M L (2012). Introduction to Environmental Engineering. New York: McGraw-Hill Education

Fang F, Han H (2018). Effect of catalytic ozonation coupling with activated carbon adsorption on organic compounds removal treating RO concentrate from coal gasification wastewater. Ozone Science and Engineering, 40(4): 275–283

Gabelich C J, Rahardianto A, Northrup C R, Yun T I, Cohen Y (2011). Process evaluation of intermediate chemical demineralization for water recovery enhancement in production-scale brackish water desalting. Desalination, 272(1–3): 36–45

Gabelich C J, Williams M D, Rahardianto A, Franklin J C, Cohen Y (2007). High-recovery reverse osmosis desalination using intermediate chemical demineralization. Journal of Membrane Science, 301(1–2): 131–141

Gui X, Xu W, Cao H, Ning P, Zhang Y, Li Y, Sheng Y (2019). A novel phenol and ammonia recovery process for coal gasification waste-water altering the bacterial community and increasing pollutants removal in anaerobic/anoxic/aerobic system. Science of the Total Environment, 661: 203–211

Guo C, Cao Q, Chen B, Yang S, Qian Y (2019). Development of synergistic extraction process for highly efficient removal of phenols from coal gasification wastewater. Journal of Cleaner Production, 211: 380–386

Jamil S, Jeong S, Vigneswaran S (2016). Application ofpressure assisted forward osmosis for water purification and reuse of reverse osmosis concentrate from a water reclamation plant. Separation and Purification Technology, 171: 182–190

Jamil S, Loganathan P, Kazner C, Vigneswaran S (2015). Forward osmosis treatment for volume minimisation of reverse osmosis concentrate from a water reclamation plant and removal of organic micropollutants. Desalination, 372: 32–38

Jia S, Han Y, Zhuang H, Han H, Li K (2017). Simultaneous removal of organic matter and salt ions from coal gasification wastewater RO concentrate and microorganisms succession in a MBR. Bioresource Technology, 241: 517–524

Lan M, Li M, Liu J, Quan X, Li Y, Li B (2018). Coal chemical reverse osmosis concentrate treatment by membrane-aerated biofilm reactor system. Bioresource Technology, 270: 120–128

Latour I, Miranda R, Blanco A (2016). Optimization of silica removal with magnesium chloride in papermaking effluents: mechanistic and kinetic studies. Environmental Science and Pollution Research International, 23(4): 3707–3717

Lee S, Kim Y C (2017). Calcium carbonate scaling by reverse draw solute diffusion in a forward osmosis membrane for shale gas wastewater treatment. Journal of Membrane Science, 522: 257–266

Li X, Hasson D, Semiat R, Shemer H (2019). Intermediate concentrate demineralization techniques for enhanced brackish water reverse osmosis water recovery: A review. Desalination, 466: 24–35

Liu Z Q, You L, Xiong X, Wang Q, Yan Y, Tu J, Cui Y H, Li X Y, Wen G, Wu X (2019). Potential of the integration of coagulation and ozonation as a pretreatment of reverse osmosis concentrate from coal gasification wastewater reclamation. Chemosphere, 222: 696–704

McCutcheon J R, McGinnis R L, Elimelech M (2006). Desalination by ammonia-carbon dioxide forward osmosis: Influence of draw and feed solution concentrations on process performance. Journal of Membrane Science, 278(1–2): 114–123

McGinnis R L, Hancock N T, Nowosielski-Slepowron M S, Mcgurgan G D (2013). Pilot demonstration of the NH3/CO2 forward osmosis desalination process on high salinity brines. Desalination, 312: 67–74

Mohammadesmaeili F, Badr M K, Abbaszadegan M, Fox P (2010). Byproduct recovery from reclaimed water reverse osmosis concentrate using lime and soda-ash treatment. Water Environment Research, 82(4): 342–350

Parks J L, Edwards M (2006). Precipitative removal of As, Ba, B, Cr, Sr, and V using sodium carbonate. Journal of Environmental Engineering, 132(5): 489–496

Pramanik B K, Shu L, Jegatheesan V (2017). A review of the management and treatment of brine solutions. Environmental Science. Water Research & Technology, 3(4): 625–658

Rioyo J, Aravinthan V, Bundschuh J (2019). The effect of ‘High-pH pretreatment’ on RO concentrate minimization in a groundwater desalination facility using batch air gap membrane distillation. Separation and Purification Technology, 227: 115699

Rioyo J, Aravinthan V, Bundschuh J, Lynch M (2018). Research on ‘high-pH precipitation treatment’ for RO concentrate minimization and salt recovery in a municipal groundwater desalination facility. Desalination, 439: 168–178

Shaffer D L, Werber J R, Jaramillo H, Lin S, Elimelech M (2015). Forward osmosis: Where are we now? Desalination, 356: 271–284

Shi J, Dang Y, Qu D, Sun D (2019a). Effective treatment of reverse osmosis concentrate from incineration leachate using direct contact membrane distillation coupled with a NaOH/PAM pre-treatment process. Chemosphere, 220: 195–203

Shi J, Han Y, Xu C, Han H (2019b). Anaerobic bioaugmentation hydrolysis of selected nitrogen heterocyclic compound in coal gasification wastewater. Bioresource Technology, 278: 223–230

Shi J, Xu C, Han Y, Han H (2019c). Enhanced anaerobic biodegradation efficiency and mechanism of quinoline, pyridine, and indole in coal gasification wastewater. Chemical Engineering Journal, 361: 1019–1029

Subramani A, Cryer E, Liu L, Lehman S, Ning R Y, Jacangelo J G (2012). Impact of intermediate concentrate softening on feed water recovery of reverse osmosis process during treatment of mining contaminated groundwater. Separation and Purification Technology, 88: 138–145

Tong T, Elimelech M (2016). The global rise of zero liquid discharge for wastewater management: Drivers, technologies, and future directions. Environmental Science & Technology, 50(13): 6846–6855

Wang W, Han H (2012). Recovery strategies for tackling the impact of phenolic compounds in a UASB reactor treating coal gasification wastewater. Bioresource Technology, 103(1): 95–100

Wang Y N, Jarvela E, Wei J, Zhang M, Kyllonen H, Wang R, Tang C Y (2016). Gypsum scaling and membrane integrity of osmotically driven membranes: The effect of membrane materials and operating conditions. Desalination, 377: 1–10

Xie M, Tang C Y, Gray S R (2016). Spacer-induced forward osmosis membrane integrity loss during gypsum scaling. Desalination, 392: 85–90

Xue W, Zaw M, An X, Hu Y, Tabucanon A S (2020). Sea salt bittern-driven forward osmosis for nutrient recovery from black water: A dual waste-to-resource innovation via the osmotic membrane process. Frontiers of Environmental Science & Engineering, 14(2): 32

You S J, Wang X H, Zhong M, Zhong Y J, Yu C, Ren N Q (2012). Temperature as a factor affecting transmembrane water flux in forward osmosis: Steady-state modeling and experimental validation. Chemical Engineering Journal, 198–199: 52–60

Zhang M, Hou D, She Q, Tang C Y (2014). Gypsum scaling in pressure retarded osmosis: Experiments, mechanisms and implications. Water Research, 48: 387–395

Zhang M, She Q, Yan X, Tang C Y (2017). Effect of reverse solute diffusion on scaling in forward osmosis: A new control strategy by tailoring draw solution chemistry. Desalination, 401: 230–237

Zhang X, Lin J, Ye W, Zhou W, Jia X, Zhao S, Ye C (2019). Potential of coagulation/GAC adsorption combined with UV/H2O2 and ozonation for removing dissolved organic matter from secondary RO concentrate. Journal of Chemical Technology and Biotechnology (Oxford, Oxfordshire), 94(4): 1091–1099

Zhao S, Zou L, Tang C Y, Mulcahy D (2012). Recent developments in forward osmosis: Opportunities and challenges. Journal of Membrane Science, 396: 1–21

Zhao X, Wu Y, Zhang X, Tong X, Yu T, Wang Y, Ikuno N, Ishii K, Hu H (2019). Ozonation as an efficient pretreatment method to alleviate reverse osmosis membrane fouling caused by complexes of humic acid and calcium ion. Frontiers of Environmental Science & Engineering, 13(4): 55

Zheng L, Wang X, Wang X (2015). Reuse of reverse osmosis concentrate in textile and dyeing industry by combined process of persulfate oxidation and lime-soda softening. Journal of Cleaner Production, 108: 525–533

Zhu H, Han Y, Ma W, Han H, Ma W, Xu C (2018). New insights into enhanced anaerobic degradation of coal gasification wastewater (CGW) with the assistance of graphene. Bioresource Technology, 262: 302–309

Acknowledgements

This work was supported by the National Key Technology R&D Program (No. 2019YFC0408503) and State Key Laboratory of Urban Water Resource and Environment (No. 20180X09).

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• Forward osmosis (FO) coupled with chemical softening for CCI ROC minimization

• Effective removal of scale precursor ions by lime-soda ash softening

• Enhanced water recovery from 54% to 86% by mitigation of FO membrane scaling

• High-purity CaCO3 was recovered from the softening sludge

• Membrane cleaning efficiency of 88.5% was obtained by EDTA for softened ROC

Rights and permissions

About this article

Cite this article

Lu, J., You, S. & Wang, X. Forward osmosis coupled with lime-soda ash softening for volume minimization of reverse osmosis concentrate and CaCO3 recovery: A case study on the coal chemical industry. Front. Environ. Sci. Eng. 15, 9 (2021). https://doi.org/10.1007/s11783-020-1301-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11783-020-1301-6