Abstract

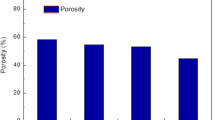

Polyvinylidene fluoride grafted with poly(ethylene glycol) methyl ether methacrylate (PVDF-g-PEGMA) was synthesized using atomic transfer radical polymerization (ATRP) at different reaction times (9 h, 19 h, and 29 h). The corresponding conversion rates were 10%, 20% and 30%, respectively. PVDF was blended with the copolymer mixture containing PVDF-g-PEGMA, solvent and residual PEGMA under different reaction times. In this study, we explored the effect of the copolymer mixture additives with different synthesis times on cast membrane performance. Increasing the reaction time of PVDF-g-PEGMA causes more PVDF-g-PEGMA and less residual PEGMA to be found in the casting solution. Incremental PVDF-g-PEGMA can dramatically increase the viscosity of the casting solution. An overly high viscosity led to a delayed phase inversion, thus hindering PEGMA segments in PVDF-g-PEGMA from migrating to the membrane surface. However, more residual PEGMA contributed to helping more PEGMA segments migrate to the membrane surface. The pure water fluxes of the blended membrane with reaction times of 9 h, 19 h, and 29 h are 5445 L∙m–2∙h–1, 1068 L∙m–2∙h–1 and 1179 L∙m–2∙h–1, respectively, at 0.07 MPa. Delayed phase inversion can form smaller surface pore size distributions, thus decreasing the water flux for the membranes with PVDF-g-PEGMA at 19 h and 29 h. Therefore, we can control the membrane pore size distribution by decreasing the reaction time of PVDF-g-PEGMA to obtain a better flux performance. The membrane with PVDF-g-PEGMA at 19 h exhibits the best foulant rejection and cleaning recovery due to its narrow pore size distribution and high surface oxygen content.

Similar content being viewed by others

References

Kang G D, Cao Y M. Application and modification of poly (vinylidene fluoride) (PVDF) membranes–A review. Journal of Membrane Science, 2014, 463: 145–165

Liu F, Hashim N A, Liu Y T, Abed M R M, Li K. Progress in the production and modification of PVDF membranes. Journal of Membrane Science, 2011, 375(1–2): 1–27

Moghimifar V, Raisi A, Aroujalian A. Surface modification of polyethersulfone ultrafiltration membranes by corona plasma-assisted coating TiO2 nanoparticles. Journal of Membrane Science, 2014, 461: 69–80

Ni L, Meng J Q, Li X G, Zhang Y F. TFC RO membrane for chlorine resistance and antifouling performance improvement. Journal of Membrane Science, 2014, 451: 205–215

Zhao X T, Su Y L, Chen W J, Peng J M, Jiang Z Y. Grafting perfluoroalkyl groups onto polyacrylonitrile membrane surface for improved fouling release property. Journal of Membrane Science, 2012, 415–416: 824–834

Ren P F, Fang Y, Wan L S, Ye X Y, Xu Z K. Surface modification of polypropylene microfiltration membrane by grafting poly(sulfobetaine methacrylate) and poly(ethylene glycol): oxidative stability and antifouling capability. Journal of Membrane Science, 2015, 492: 249–256

Chen Y Q, Wei M J, Wang Y. Upgrading polysulfone ultrafiltration membranes by blending with amphiphilic block copolymers: beyond surface segregation. Journal of Membrane Science, 2016, 505: 53–60

Liu Y N, Su Y L, Zhao X T, Li Y F, Zhang R N, Jiang Z Y. Improved antifouling properties of polyethersulfone membrane by blending the amphiphilic surface modifier with crosslinked hydrophobic segments. Journal of Membrane Science, 2015, 486: 195–206

Rajasekhar T, Trinadh M, Veera Babu P, Sainath A V S, Reddy A V R. Oil–water emulsion separation using ultrafiltration membranes based on novel blends of poly(vinylidene fluoride) and amphiphilic tri-block copolymer containing carboxylic acid functional group. Journal of Membrane Science, 2015, 481: 82–93

Chen C, Tang L, Liu B C, Zhang X, Crittenden J, Chen K L, Chen Y S. Forming mechanism study of unique pillar-like and defect-free PVDF ultrafiltration membranes with high flux. Journal of Membrane Science, 2015, 487: 1–11

Liu B C, Chen C, Li T, Crittenden J, Chen Y S. High performance ultrafiltration membrane composed of PVDF blended with its derivative copolymer PVDF-g-PEGMA. Journal of Membrane Science, 2013, 445: 66–75

Ochoa N. Effect of hydrophilicity on fouling of an emulsified oil wastewater with PVDF/PMMA membranes. Journal of Membrane Science, 2003, 226(1–2): 203–211

Yuan Z, Dan L X. Porous PVDF/TPU blends asymmetric hollow fiber membranes prepared with the use of hydrophilic additive PVP (K30). Desalination, 2008, 223(1–3): 438–447

Liu B C, Chen C, Zhao P J, Li T, Liu C H, Wang Q Y, Chen Y S, Crittenden J. Thin-film composite forward osmosis membranes with substrate layer composed of polysulfone blended with PEG or polysulfone grafted PEG methyl ether methacrylate. Frontiers of Chemical Science and Engineering, 2016, 10(4): 562–574

Xu Z W, Wu T F, Shi J, Teng K Y, Wang W, Ma M J, Li J, Qian X M, Li C Y, Fan J T. Photocatalytic antifouling PVDF ultrafiltration membranes based on synergy of graphene oxide and TiO2 for water treatment. Journal of Membrane Science, 2016, 520: 281–293

Liang S, Gao P, Gao X Q, Xiao K, Huang X. Improved blending strategy for membrane modification by virtue of surface segregation using surface-tailored amphiphilic nanoparticles. Frontiers of Environmental Science & Engineering, 2016, 10 (6):113–121 doi:10.1007/s11783-016-0875-5

Zhao Y H, Qian Y L, Zhu B K, Xu Y Y. Modification of porous poly (vinylidene fluoride) membrane using amphiphilic polymers with different structures in phase inversion process. Journal of Membrane Science, 2008, 310(1–2): 567–576

Minehara H, Dan K, Ito Y, Takabatake H, Henmi M. Quantitative evaluation of fouling resistance of PVDF/PMMA-g-PEO polymer blend membranes for membrane bioreactor. Journal of Membrane Science, 2014, 466: 211–219

Ma W Z, Rajabzadeh S, Shaikh A R, Kakihana Y, Sun Y C, Matsuyama H. Effect of type of poly(ethylene glycol) (PEG) based amphiphilic copolymer on antifouling properties of copolymer/poly (vinylidene fluoride) (PVDF) blend membranes. Journal of Membrane Science, 2016, 514: 429–439

Venault A, Liu Y H, Wu J R, Yang H S, Chang Y, Lai J Y, Aimar P. Low-biofouling membranes prepared by liquid-induced phase separation of the PVDF/polystyrene-b-poly (ethylene glycol) methacrylate blend. Journal of Membrane Science, 2014, 450: 340–350

Venault A, Wu J R, Chang Y, Aimar P. Fabricating hemocompatible bi-continuous PE Gylated PVDF membranes via vapor-induced phase inversion. Journal of Membrane Science, 2014, 470: 18–29

Carretier S, Chen L A, Venault A, Yang Z R, Aimar P, Chang Y. Design of PVDF/PEGMA-b-PS-b-PEGMA membranes by VIPS for improved biofouling mitigation. Journal of Membrane Science, 2016, 510: 355–369

Moghareh Abed M R, Kumbharkar S C, Groth A M, Li K. Economical production of PVDF-g-POEM for use as a blend in preparation of PVDF based hydrophilic hollow fibre membranes. Separation and Purification Technology, 2013, 106: 47–55

Hashim N A, Liu F, Li K. A simplified method for preparation of hydrophilic PVDF membranes from an amphiphilic graft copolymer. Journal of Membrane Science, 2009, 345(1–2): 134–141

Hester J F, Banerjee P, Won Y Y, Akthakul A, Acar M H, Mayes A M. ATRP of amphiphilic graft copolymers based on PVDF and their use as membrane additives. Macromolecules, 2002, 35(20): 7652–7661

Wang J S, Matyjaszewski K. Controlled/“living” radical polymerization. atom transfer radical polymerization in the presence of transition-metal complexes. Journal of the American Chemical Society, 1995, 117(20): 5614–5615

Kato M, Kamigaito M, Sawamoto M, Higashimura T. Polymerization of methyl methacrylate with the carbon tetrachloride/dichlorotris-( triphenylphosphine)ruthenium(ii)/methylaluminum Bis(2,6- di-tert-butylphenoxide) initiating system: possibility of living radical polymerization. Macromolecules, 1995, 28(5): 1721–1723

Katsoufidou K, Yiantsios S G, Karabelas A J. An experimental study of UF membrane fouling by humic acid and sodium alginate solutions: the effect of backwashing on flux recovery. Desalination, 2008, 220(1–3): 214–227

Ye Y, Chen V, Fane A G. Modeling long-term subcritical filtration of model EPS solutions. Desalination, 2006, 191(1–3): 318–327

Kim H C, Dempsey B A. Membrane fouling due to alginate, SMP, EfOM, humic acid, and NOM. Journal of Membrane Science, 2013, 428: 190–197

Listiarini K, Chun W, Sun D D, Leckie J O. Fouling mechanism and resistance analyses of systems containing sodium alginate, calcium, alum and their combination in dead-end fouling of nanofiltration membranes. Journal of Membrane Science, 2009, 344(1–2): 244–251

Katsoufidou K, Yiantsios S G, Karabelas A J. Experimental study of ultrafiltration membrane fouling by sodium alginate and flux recovery by backwashing. Journal of Membrane Science, 2007, 300(1–2): 137–146

Ang W S, Lee S, Elimelech M. Chemical and physical aspects of cleaning of organic-fouled reverse osmosis membranes. Journal of Membrane Science, 2006, 272(1–2): 198–210

Awanis Hashim N, Liu F, Moghareh Abed M R, Li K. Chemistry in spinning solutions: Surface modification of PVDF membranes during phase inversion. Journal of Membrane Science, 2012, 415–416: 399–411

Peinemann K V, Abetz V, Simon P F W. Asymmetric superstructure formed in a block copolymer via phase separation. Nature Materials, 2007, 6(12): 992–996

Acknowledgements

We are extremely grateful to the National Natural Science Foundation of China (Nos: 51278317 and 51678377), Key Projects in the Science & Technology Program of Hainan Province (No: zdkj2016022), the Applied Basic Research of Sichuan Province (No: 2017JY0238), and the Litree Purifying Technology Co., Ltd (No: 16H0155).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, S., Li, T., Chen, C. et al. PVDF ultrafiltration membranes of controlled performance via blending PVDF-g-PEGMA copolymer synthesized under different reaction times. Front. Environ. Sci. Eng. 12, 3 (2018). https://doi.org/10.1007/s11783-017-0980-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11783-017-0980-0