Abstract

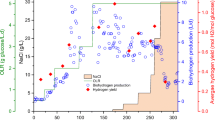

A low pH, ethanol-type fermentation process was evaluated for wastewater treatment and bio-hydrogen production from acidic beet sugar factory wastewater in a continuous stirred tank reactor (CSTR) with an effective volume of 9.6 L by anaerobic mixed cultures in this present study. After inoculating with aerobic activated sludge and operating at organic loading rate (OLR) of 12 kgCOD·m−3·d−1, HRT of 8h, and temperature of 35°C for 28 days, the CSTR achieved stable ethanol-type fermentation. When OLR was further increased to 18 kgCOD·m−3·d−1 on the 53rd day, ethanol-type fermentation dominant microflora was enhanced. The liquid fermentation products, including volatile fatty acids (VFAs) and ethanol, stabilized at 1493 mg·L−1 in the bioreactor. Effluent pH, oxidation-reduction potential (ORP), and alkalinity ranged at 4.1–4.5, −250-(−290) mV, and 230–260 mgCaCO3·L−1. The specific hydrogen production rate of anaerobic activated sludge was 0.1 L·gMLVSS−1·d−1 and the COD removal efficiency was 45%. The experimental results showed that the CSTR system had good operation stability and microbial activity, which led to high substrate conversion rate and hydrogen production ability.

Similar content being viewed by others

References

Sivaramakrishna D, Sreekanth D, Himabindu V, Anjaneyulu Y. Biological hydrogen production from probiotic wastewater as substrate by selectively enriched anaerobic mixed microflora. Renewable Energy, 2009, 34(3): 937–940

Hawkes F R, Hussy I, Kyazze G, Dinsdale R, Hawkes D L. Continuous dark fermentative hydrogen production by mesophilic microflora: principles and progress. International Journal of Hydrogen Energy, 2007, 32(2): 172–184

Manish S, Banerjee R. Comparison of biohydrogen production processes. International Journal of Hydrogen Energy, 2008, 33(1): 279–286

Hallenbeck P C, Benemann J R. Biological hydrogen production: fundamentals and limiting processes. International Journal of Hydrogen Energy, 2002, 27(11–12): 1185–1193

Nath K, Das D. Improvement of fermentative hydrogen production: various approaches. Applied Microbiology and Biotechnology, 2004, 65(5): 520–529

Okamoto M, Miyahara T, Mizuno O, Noike T. Biological hydrogen potential of materials characteristic of the organic fraction of municipal solid wastes.Water Science and Technology, 2000, 41(3): 25–32

Nandi R, Sengupta S. Microbial production of hydrogen: an overview. Critical Reviews in Microbiology, 1998, 24(1): 61–84

Wu K J, Chang C F, Chang J S. Simultaneous production of biohydrogen and bioethanol with fluidized-bed and packed-bed bioreactors containing immobilized anaerobic sludge. Process Biochemistry, 2007, 42(7): 1165–1171

Lin C Y, Lee C Y, Tseng I C, Shiao I Z. Biohydrogen production from sucrose using base-enriched anaerobic mixed microflora. Process Biochemistry, 2006, 41(4): 915–919

Show K Y, Zhang Z P, Tay J H, Liang D T, Lee D J, Jiang W J. Production of hydrogen in a granular sludge-based anaerobic continuous stirred tank reactor. International Journal of Hydrogen Energy, 2007, 32(18): 4744–4753

Khanal S K, Chen W H, Li L, Sung S. Biohydrogen production in continuous-flow reactor using mixed microbial culture. Water Environment Research, 2006, 78(2): 110–117

Chen W H, Chen S Y, Khanal S K, Sung S. Kinetic study of biological hydrogen production by anaerobic fermentation. International Journal of Hydrogen Energy, 2006, 31(15): 2170–2178

Ginkel S V, Sung S, Lay J J. Biohydrogen production as a function of pH and substrate concentration. Environmental Science and Technology, 2001, 35(24): 4726–4730

Jiménez AM, Borja R, Martín A. Aerobic-anaerobic biodegradation of beet molasses alcoholic fermentation wastewater. Process Biochemistry, 2003, 38(9): 1275–1284

Farhadian M, Borghei M, Umrania V V. Treatment of beet sugar wastewater by UAFB bioprocess. Bioresource Technology, 2007, 98(16): 3080–3083

Denac M, Miguel A, Dunn I J. Modeling dynamic experiments on the anaerobic degradation of molasses wastewater. Biotechnology and Bioengineering, 1988, 31(1): 1–10

Güven G, Perendeci A, Tanyolac A. Electrochemical treatment of simulated beet sugar factory wastewater. Chemical Engineering Journal, 2009, 151(1–3): 149–159

Ren N Q, Wang B Z, Huang J C. Ethanol-type fermentation from carbohydrate in high rate acidogenic reactor. Biotechnology and Bioengineering, 1997, 54(5): 428–433

APHA. Standard methods for the examination of water and wastewater, 20th ed., Washington, DC, USA: American Public Health Association, 1998

Li J Z, Li N, Zhang N, Ouyang H. Hydrogen production from organic wastewater by fermentative acidogenic activated sludge under condition of continuous flow. Journal of Chemical Industry and Engineering (China), 2004, 55(Suppl.): 75–79 (in Chinese)

Ren N Q, Chen X L, Zhao D. Control of fermentation types in continuous flow acidogenic reactors: effects of pH and redox potential. Journal of Harbin Institute of Technology (New Series), 2001, 8(2): 116–119 (in Chinese)

Zhang Z P, Show K Y, Tay J H, Liang D W, Lee D J, Jiang W J. Effect of hydraulic retention time on biohydrogen production and anaerobic microbial community. Process Biochemistry, 2006, 41(10): 2118–2123

Hwang MH, Jang N J, Hyun S H, Kim I S. Anaerobic bio-hydrogen production from ethanol fermentation: the role of pH. Journal of Biotechnology, 2004, 111(3): 297–309

Li J Z, Li B K, Zhu G F, Ren N Q, Bo L X, He J G. Hydrogen production from diluted molasses by anaerobic hydrogen producing bacteria in an anaerobic baffled reactor (ABR). International Journal of Hydrogen Energy, 2007, 32(15): 3274–3283

Khanal S K, Chen W H, Li L, Sung S. Biological hydrogen production: effect of pH and intermediate products. International Journal of Hydrogen Energy, 2004, 29(11): 1123–1131

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, G., Liu, C., Li, J. et al. Fermentative hydrogen production from beet sugar factory wastewater treatment in a continuous stirred tank reactor using anaerobic mixed consortia. Front. Environ. Sci. Eng. 7, 143–150 (2013). https://doi.org/10.1007/s11783-012-0456-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11783-012-0456-1