Abstract

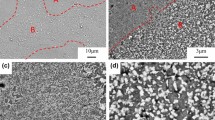

Al7075 alloy is a typical aviation aluminum with good mechanical properties and anodic oxidation effect. Laser engineered net shaping technology has unique advantages in the integrated forming of high-performance large aircraft structural parts. The manufacturing of 7075 aluminum alloy structural parts by laser engineered net shaping technology has become an important development direction in the future aerospace field. Electrochemical corrosion resistance of aluminum alloys is of vital importance to improve reliability and life-span of lightweight components. A comparative study on microstructure and anti-corrosion performance of Al7075 alloy prepared by laser additive manufacturing and forging technology was conducted. There are hole defects in LENS-fabricated Al7075 alloy with uniformly distributed η phase. No defects are observed in Al7075 forgings. The large S phase particles and small ellipsoidal η phase particles are found in Al matrix. The corrosion mechanisms were revealed according to the analysis of polarization curves and corrosion morphology. It was found that compared with that prepared by forgings, the additive manufactured samples have lower corrosion tendency and higher corrosion rate. Corrosion occurred preferentially at the hole defects. The incomplete passivation film at the defects leads to the formation of a local cell composed of the internal Al, corrosion solution and the surrounding passive film, which further aggravates the corrosion.

摘要

Al7075 合金是一种典型的航空铝合金,具有良好的力学性能和阳极氧化效果。激光近净成形技术在高性能大型飞机结构件的整体成形中具有独特的优势。利用激光近净成形制造 7075 铝合金构件已成为未来航空航天领域的重要发展方向。铝合金的耐电化学腐蚀性能对提高轻量化构件的可靠性和寿命具有重要意义。本文对激光近净成形和锻造工艺制备的 Al7075 合金的组织和耐蚀性能进行了对比研究。发现激光近净成形制造的 Al7075 合金中存在孔隙缺陷,η相分布均匀。在 Al7075 锻件中未发现任何冶金缺陷,铝基体中存在较大的S 相颗粒和较小的 η 相颗粒。随后,通过极化曲线和腐蚀形貌分析,揭示了不同工艺制造 Al7075 合金的腐耐腐蚀性能和腐蚀机理。与锻件相比,激光近净成形制备的试样具有较低的腐蚀倾向和较快的腐蚀速率。腐蚀优先发生在孔洞缺陷处。缺陷处的钝化膜不完整,形成了由铝、腐蚀溶液和周围钝化膜组成的局部电池,加剧了腐蚀。

Similar content being viewed by others

References

ZHANG Jin-liang, GAO Jian-bao, SONG Bo, ZHANG Li-jun, HAN Chang-jun, CAI Chao, ZHOU Kun, SHI Yu-sheng. A novel crack-free Ti-modified Al-Cu-Mg alloy designed for selective laser melting [J]. Additive Manufacturing, 2021, 38: 101829. DOI: https://doi.org/10.1016/j.addma.2020.101829.

CHEN Jing, PAN Qing-lin, YU Xue-hong, LI Meng-jia, ZOU Hao, XIANG Hao, HUANG Zhi-qi, HU Quan. Effect of annealing treatment on the microstructure and fatigue crack growth behavior of Al-Zn-Mg-Sc-Zr alloy [J]. Journal of Central South University, 2018, 25(5): 961–975. DOI: https://doi.org/10.1007/s11771-018-3797-5.

ZHANG Jin-liang, SONG Bo, WEI Qing-song, BOURELL D, SHI Yu-sheng. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends [J]. Journal of Materials Science & Technology, 2018, 35: 270–284. DOI: https://doi.org/10.1016/j.jmst.2018.09.004.

LI Rui-di, WANG Min-bo, YUAN Tie-chui, SONG Bo, CHEN Chao, ZHOU Ke-chao, CAO Peng. Selective laser melting of a novel Sc and Zr modified Al-6.2 Mg alloy: Processing, microstructure, and properties [J]. Powder Tenchnology, 2017, 319: 117–128. DOI: https://doi.org/10.1016/j.powtec.2017.06.050.

ZHANG Jin-liang, SONG Bo, YANG Lei, LIU Rui-jie, ZHANG Lei, SHI Yu-sheng. Microstructure evolution and mechanical properties of TiB/Ti6Al4V gradient-material lattice structure fabricated by laser powder bed fusion [J]. Composites Part B-Engineering, 2020, 202: 108419. DOI: https://doi.org/10.1016/j.compositesb.2020.108417.

YANG Xin, REN Yao-jia, LIU Shi-feng, WANG Qing-juan, SHI Ming-jun. Microstructure and tensile property of SLM 316L stainless steel manufactured with fine and coarse powder mixtures [J]. Journal of Central South University, 2020, 27(2): 334–343. DOI: https://doi.org/10.1007/s11771-020-4299-9.

ZINDANI D, MAITY S R, BHOWMIK S. Decision making tools for optimal material selection: A review [J]. Journal of Central South University, 2020, 27(3): 629–673. DOI: https://doi.org/10.1007/s11771-020-4322-1.

ZHAI Yu-wei, LADOS D A, BROWN E J, VIGILANTE G N. Understanding the microstructure and mechanical properties of Ti-6Al-4V and Inconel 718 alloys manufactured by laser engineered net shaping [J]. Additive Manufacturing, 2019, 27: 334–344. DOI: https://doi.org/10.1016/j.addma.2019.02.017.

SHI Wen-xiong, REN Zhang-yu, HE Wei, HOU Jun-song, XIE Hui-min, LIU Sheng. A technique combining laser spot thermography and neural network for surface crack detection in laser engineered net shaping [J]. Optics and Lasers in Engineering, 2021, 138: 106431. DOI: https://doi.org/10.1016/j.optlaseng.2020.106431.

ZHAI Y, LADOS D A, LAGOY J L. Additive manufacturing: Making imagination the major limitation [J]. The Journal of the Minerals, Metals & Materials Society, 2014, 66: 808–816. DOI: https://link.springer.com/article/10.1007/s11837-014-0886-2.

CHEN Hai-xiang, KONG De-jun. Comparison on electrochemical corrosion performances of arc and laser thermal sprayed Al-Ti-Ni coatings in marine environment [J]. Materials Chemistry & Physics, 2020, 251: 123200. DOI: https://doi.org/10.1016/j.matchemphys.2020.123200.

ABIOLA O K, OTAIGBE J O E. Effect of common water contaminants on the corrosion of aluminium alloys in ethylene glycol-water solution [J]. Corrosion Science, 2008, 50: 242–247. DOI: doi:https://doi.org/10.1016/j.corsci.2007.06.01

ZHANG Yuan-jie, SONG Bo, MING Jun, YAN Qian, WANG Min, CAI Chao, ZHANG Cheng, SHI Yu-sheng. Corrosion mechanism of amorphous alloy strengthened stainless steel composite fabricated by selective laser melting [J]. Corrosion Science, 2020, 163: 108241. DOI: https://doi.org/10.1016/j.corsci.2019.108241.

TIAN Wen-ming, LI Song-mei, WANG Bo, LIU Jian-hua, YU Mei. Pitting corrosion of naturally aged AA 7075 aluminum alloys with bimodal grain size [J]. Corrosion Science, 2016, 113: 1–16. DOI: https://doi.org/10.1016/j.corsci.2016.09.013.

CABRINI M, LORENZI S, PASTORE T, TESTA C, MANFREDI D, LORUSSO M, CALIGNANO F, PAVESE M, ANDREATTA F. Corrosion behavior of AlSi10Mg alloy produced by laser powder bed fusion under chloride exposure [J]. Corrosion Science, 2019, 152: 101–108. DOI: https://doi.org/10.1016/j.corsci.2019.03.010.

GHARBI O, JIANG D, FEENSTRA D R, KAIRY S K, WU Y, HUTCHINSON C R, BIRBILIS N. On the corrosion of additively manufactured aluminium alloy AA2024 prepared by selective laser melting [J]. Corrosion Science, 2018, 1743: 93–106. DOI: https://doi.org/10.1016/j.corsci.2018.08.019.

ZHANG Cheng, LI Xu-min, LIU Si-qi, LIU Hao, YU Longjiang, LIU Lin. 3D printing of Zr-based bulk metallic glasses and components for potential biomedical applications [J]. Journal of Alloys & Compounds, 2019, 790: 963–973. DOI: https://doi.org/10.1016/j.jallcom.2019.03.275.

LIU Gui-li, FANG Ge-liang. Grain-boundary segregation and corrosion mechanism of Al-Zn-Mg-Cu ultra high strength aluminum alloys [J]. Rare Metal Materials and Engineering, 2009, 28: 1598–1601. DOI: https://doi.org/10.3321/j.issn:1002-185X.2009.09.021. (in Chinese)

XIAO S, WANG C, CHEN T. The application of the discrete variational method in the density functional theory to chemistry and materials physics [M]. Beijing: Science Press, 1998. (in Chinese)

TSURU T, YAMAGUCHI M, EBIHARA K, ITAKURA M, SHIIHARA Y, MATSUDA K, TODA H. First-principles study of hydrogen segregation at the MgZn2, precipitate in Al-Mg-Zn alloys [J]. Computational Materials Science, 2018, 148: 301–306. DOI: https://doi.org/10.1016/j.commatsci.2018.03.009.

ZOU Xiu-liang, YAN Hong, CHEN Xiao-hui. Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 2146–2155. DOI: https://doi.org/10.1016/S1003-6326(17)60240-1

JIANG Fu-lin, ZUROB H S, PURDY G R, ZHANG Hui. Characterizing precipitate evolution of an Al-Zn-Mg-Cu-based commercial alloy during artificial aging and non-isothermal heat treatments by in situ electrical resistivity monitoring [J]. Materials Characterization, 2016, 117: 47–56. DOI: https://doi.org/10.1016/j.matchar.2016.04.014.

YANG Wen-chao, JI Shou-xun, WANG Ming-pu, LI Zhou. Precipitation behaviour of Al-Zn-Mg-Cu alloy and diffraction analysis from η′ precipitates in four variants [J]. Journal of Alloys & Compounds, 2014, 610: 623–629. DOI: https://doi.org/10.1016/j.jallcom.2014.05.061.

ZHANG X, ZHOU X, NILSSON J O. Corrosion behaviour of AA6082 Al-Mg-Si alloy extrusion: The influence of quench cooling rate [J]. Corrosion Science, 2019, 150: 100–109. DOI: https://doi.org/10.1016/j.corsci.2019.01.030.

SANTOS-GÜEMES R, BELLÓN B, ESTEBANMANZANARES G, SEGURADO J, CAPOLUNGO L, LLORCA J. Multiscale modelling of precipitation hardening in Al-Cu alloys: Dislocation dynamics simulations and experimental validation [J]. Acta Materialia, 2020, 1880: 475–485. DOI: https://doi.org/10.1016/j.actamat.2020.02.019.

GHIAASIAAN R, AMIRKHIZ B S, SHANKAR S. Quantitative metallography of precipitating and secondary phases after strengthening treatment of net shaped casting of Al-Zn-Mg-Cu (7000) alloys [J]. Materials Science & Engineering A, 2017, 698: 206–217. DOI: https://doi.org/10.1016/j.msea.2017.05.047.

LIAO Fei, FAN Shi-tong, DENG Yun-lai, et al. First-principle calculations of mechanical properties of Al2Cu, Al2CuMg and MgZn2 intermetallics in high strength aluminum alloys [J]. Journal of Aeronautical Materials, 2016, 36: 1–8. DOI: 10.11868/j.issn.1005-5053.2016.6.001.(in Chinese)

LI J F, ZHENG Z Q, LI S C, CHEN W J, REN W D, ZHAO X S. Simulation study on function mechanism of some precipitates in localized corrosion of Al alloys [J]. Corrosion Science, 2007, 49: 2436–2449. DOI: DOI: https://doi.org/10.1016/j.corsci.2006.12.00.

Author information

Authors and Affiliations

Contributions

The overarching research goals were developed by SONG Bo, LI Rui-di, and SHI Yu-sheng. ZHANG Jin-liang and YE Jie-liang conducted the experiments, and analyzed the experimental data. The initial draft of the manuscript was written by ZHANG Jin-liang. All authors replied to reviewers’ comments and revised the final version.

Corresponding author

Additional information

Conflict of interest

ZHANG Jin-liang, YE Jie-liang, SONG Bo, LI Rui-di, and SHI Yu-sheng declare that they have no conflict of interest.

Foundation item: Project(2016YFB1100101) supported by the National Key Research and Development Program of China

Rights and permissions

About this article

Cite this article

Zhang, Jl., Ye, Jl., Song, B. et al. Comparative study on microstructure and electrochemical corrosion resistance of Al7075 alloy prepared by laser additive manufacturing and forging technology. J. Cent. South Univ. 28, 1058–1067 (2021). https://doi.org/10.1007/s11771-021-4679-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4679-9