Abstract

To study the energy storage and dissipation characteristics of deep rock under two-dimensional compression with constant confining pressure, the single cyclic loading-unloading two-dimensional compression tests were performed on granite specimens with two height-to-width (H/W) ratios under five confining pressures. Three energy density parameters (input energy density, elastic energy density and dissipated energy density) in the axial and lateral directions of granite specimens under different confining pressures were calculated using the area integral method. The experimental results show that, for the specimens with a specific H/W ratio, these three energy density parameters in the axial and lateral directions increase nonlinearly with the confining pressure as quadratic polynomial functions. Under constant confining pressure compression, the linear energy storage law of granite specimens in the axial and lateral directions was founded. Using the linear energy storage law in different directions, the elastic energy density in various directions (axial elastic energy density, lateral elastic energy density and total elastic energy density) of granite under any specific confining pressures can be calculated. When the H/W ratio varies from 1:1 to 2:1, the lateral compression energy storage coefficient increases and the corresponding axial compression energy storage coefficient decreases, while the total compression energy storage coefficient is almost independent of the H/W ratio.

摘要

为了研究深部岩石在二维等围压压缩下的能量存储和耗散特征, 对两种高宽比(1:1和2:1)的长方体花岗岩试样进行了五种围压下的一次加卸载压缩试验。利用图形积分方式获得了试样在五种围压下的轴向和侧向的输入能密度、弹性能密度和耗散能密度的值。试验结果表明: 两种高宽比下试样的三种能量密度参数值随着围压的增加而非线性增加, 呈现二次多项式函数关系; 在二维等围压压缩下, 发现了轴向和侧向上的线性储能规律。根据轴向和侧向上的线性储能规律, 可以计算花岗岩在具体围压下轴向、侧向以及总的弹性能密度的值。此外, 当高宽比从1:1 增加到2:1 时, 侧向压缩储能系数增加, 相应的轴向压缩储能系数降低, 而总的压缩储能系数与高宽比无关。

Similar content being viewed by others

References

LI X B, GONG F Q, TAO M, DONG L J, DU K, MA C D, ZHOU Z L, YIN T B. Failure mechanism and coupled static-dynamic loading theory in deep hard rock mining: A review [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2017, 9(4): 767–782. DOI: https://doi.org/10.1016/j.jrmge.2017.04.004.

SI X F, GONG F Q. Strength-weakening effect and shear-tension failure mode transformation mechanism of rockburst for fine-grained granite under triaxial unloading compression conditions [J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 131: 104347. DOI: https://doi.org/10.1016/j.ijrmms.2020.104347.

SAHOURYEH E, DYSKIN A V, GERMANOVICH L N. Crack growth under biaxial compression [J]. Engineering Fracture Mechanics, 2002, 69(18): 2187–2198. DOI: https://doi.org/10.1016/S0013-7944(02)00015-2.

MA C D, LI X B, CHEN F, XU J C. Fracturing behavior study of biaxial compression of rock subjected to dynamic disturbance load [J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(6): 1238–1244. DOI: 10.CNKI:SUN:YSLX.0.2010-06-021. (in Chinese).

LI A, SHAO G J, LEI D, ZHU Y H. Study on damage characteristics of marble under biaxial compression [J]. Journal of Hydraulic Engineering, 2012, 43(S1): 131–134. DOI: https://doi.org/10.13243/j.cnki.slxb.2012.s1.021. (in Chinese).

ZHONG Z B, DENG R G, XIAO W M, LIN F, FU X M. Experimental study on an arched opening with straight wall in hard rhyolite under biaxial test [J]. Journal of the China Railway Society, 2016, 38(8): 110–118. DOI: https://doi.org/10.3969/j.issn.1001-8360.2016.08.016. (in Chinese).

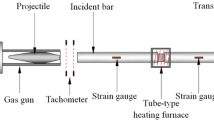

PENG J Y, LI Y H, ZHANG F P, QIU Z G. Failure process and mechanism of sandstone under combined equal biaxial static compression and impact loading [J]. Strain, 2018, 54(2): e12267. DOI: https://doi.org/10.1111/str.12267.

LIU K, ZHAO J, WU G, MAKSIMENKO A, HAQUE A, ZHANG Q B. Dynamic strength and failure modes of sandstone under biaxial compression [J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 128: 104260. DOI: https://doi.org/10.1016/j.ijrmms.2020.104260.

XIE H P, PENG R D, JU Y. Energy dissipation of rock deformation and fracture [J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(21): 3565–3570. DOI: https://doi.org/10.1016/j.jnucmat.2004.03.002. (in Chinese).

HUANG D, LI Y R. Conversion of strain energy in triaxial unloading tests on marble [J]. International Journal of Rock Mechanics and Mining Sciences, 2014, 66(1): 160–168. DOI: https://doi.org/10.1016/j.ijrmms.2013.12.001.

HE M M, HUANG B Q, ZHU C H, CHEN Y S, LI N. Energy dissipation-based method for fatigue life prediction of rock salt [J]. Rock Mechanics and Rock Engineering, 2018, 51(5): 1447–1455. DOI: https://doi.org/10.1007/s00603-018-1402-8.

ZHANG Y, FENG X T, ZHANG X W, WANG Z F, SHARIFZADEH M, YANG C X, KONG R, ZHAO J. Strain energy evolution characteristics and mechanisms of hard rocks under true triaxial compression [J]. Engineering Geology, 2019, 260: 105222. DOI: https://doi.org/10.1016/j.enggeo.2019.105222.

MCSAVENEY M J, DAVIES T R. Surface energy is not one of the energy losses in rock comminution [J]. Engineering Geology, 2009, 109: 109–113. DOI: https://doi.org/10.1016/j.enggeo.2008.11.001.

HASHEMI S S, MELKOUMIAN N. A strain energy criterion based on grain dislodgment at borehole wall in poorly cemented sands [J]. International Journal of Rock Mechanics and Mining Sciences, 2016, 87: 90–103. DOI: https://doi.org/10.1016/j.ijrmms.2016.05.013.

MUNOZ H, TAHERI A, CHANDA E K. Fracture energy-based brittleness index development and brittleness quantification by pre-peak strength parameters in rock uniaxial compression [J]. Rock Mechanics and Rock Engineering, 2016, 49(12): 4587–4606. DOI: https://doi.org/10.1007/s00603-016-1071-4.

MAHANTA B, TRIPATHY A, VISHAL V, SINGH TN, RANJITH PG. Effects of strain rate on fracture toughness and energy release rate of gas shales [J]. Engineering Geology, 2016, 218: 39–49. DOI: https://doi.org/10.1016/j.enggeo.2016.12.008.

PAN Xiao-hua, LÜ Qing. A quantitative strain energy indicator for predicting the failure of laboratory-scale rock samples: Application to shale rock [J]. Rock Mechanics and Rock Engineering, 2018, 51(9): 2689–2707. DOI: https://doi.org/10.1007/s00603-018-1480-7.

GONG F Q, YAN J Y, LI X B. A new criterion of rock burst proneness based on the linear energy storage law and the residual elastic energy index [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(9): 1993–2014. DOI: CNKI:SUN:SLSK.0.2018-09-009. (in Chinese).

KIVI I R, AMERI M, MOLLADAVOODI H. Shale brittleness evaluation based on energy balance analysis of stress-strain curves [J]. Journal of Petroleum Sci & Engineering, 2018, 167: 1–19. DOI: https://doi.org/10.1016/j.petrol.2018.03.061.

LI Y R, HUANG D, LI X A. Strain rate dependency of coarse crystal marble under uniaxial compression: Strength, deformation and strain energy [J]. Rock Mechanics and Rock Engineering, 2014, 47(4): 1153–1164. DOI: https://doi.org/10.1007/s00603-013-0472-x.

HOU P, GAO F, YANG Y G, ZHANG X X, ZHANG Z Z. Effect of the layer orientation on mechanics and energy evolution characteristics of shales under uniaxial loading [J]. International Journal of Mining Science and Technology, 2016, 26(5): 857–862. DOI: https://doi.org/10.1016/j.ijmst.2016.05.041.

MUNOZ H, TAHERI A, CHANDA E K. Rock drilling performance evaluation by an energy dissipation based rock brittleness index [J]. Rock Mechanics and Rock Engineering, 2016, 49(8): 3343–3355. DOI: https://doi.org/10.1007/s00603-016-0986-0.

MENG Q B, ZHANG M W, HAN L J, PU H, NIE T Y. Effects of acoustic emission and energy evolution of rock specimens under the uniaxial cyclic loading and unloading compression [J]. Rock Mechanics and Rock Engineering, 2016, 49(10): 3873–3886. DOI: https://doi.org/10.1007/s00603-016-1077-y.

GONG F Q, WANG Y L, LUO S. Rockburst proneness criteria for rock materials: Review and new insights [J]. Journal of Central South University, 2020, 27(10): 2793–2821. DOI: https://doi.org/10.1007/s11771-020-4511-y.

GONG F Q, YAN J Y, LI X B, LUO S. A peak-strength strain energy storage index for rock burst proneness of rock materials [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 117: 76–89. DOI: https://doi.org/10.1016/j.ijrmms.2019.03.020.

GONG F Q, YAN J Y, LUO S, LI X B. Investigation on the linear energy storage and dissipation laws of rock materials under uniaxial compression [J]. Rock Mech Rock Eng, 2019, 52(11): 4237–4255. DOI: https://doi.org/10.1007/s00603-019-01842-4.

LI L Y, WANG R X, MA X, ZHAO Z W, XU Y Y, LU J F. The energy variety analysis of rock under biaxial compression [J]. Journal of China Coal Society, 2010, 35(12): 2033–2038. DOI: https://doi.org/10.1016/S1876-3804(11)60004-9. (in Chinese).

WANG Y F, ZHENG X J, WANG L P, ZHOU H B. Energy evolution mechanism in failure process of coalrock and energy strength criterion under biaxial loading [J]. Industrial Construction, 2015, 45(5): 87–92, 110. DOI:https://doi.org/10.13204/j.gyjz201505019. (in Chinese)

YANG Y F, TANG C A, XIA K W. Study on crack curving and branching mechanism in quasi-brittle materials under dynamic biaxial loading [J]. International Journal of Fracture, 2012, 177(1): 53–72. DOI: https://doi.org/10.1007/s10704-012-9755-6.

FAIRHURST C E, HUDSON J A. Draft ISRM suggested method for the complete stress-strain curve for intact rock in uniaxial compression [J]. International Journal of Rock Mechanics and Mining Sciences, 1999, 36(3): 281–289. DOI: https://doi.org/10.1016/S0148-9062(99)00006-6.

MOGI K. Experimental rock mechanics [M]. London: Taylor & Francis Group, 2007.

AMADEI B, ROBINSON M J. Strength of rock in multiaxial loading conditions [C]//Proceedings of 27th US Rock Mech Symposium. Alabama: Tuscaloosa. 1983, 47–55. https://www.researchgate.net/publication/254543007.

LIANG C Y, ZHANG Q B, LI X, XIN P. The effect of specimen shape and strain rate on uniaxial compressive behavior of rock material [J]. Bulletin of Engineering Geology and the Environment, 2016, 75(4): 1669–1681. DOI: https://doi.org/10.1007/s10064-015-0811-0.

ZHU W S, YANG W M, LI X J, XIANG L, YU D J. Study on splitting failure in rock masses by simulation test, site monitoring and energy model [J]. Tunnelling and Underground Space Technology, 2014, 41: 152–164. DOI: https://doi.org/10.1016/j.tust.2013.12.007.

ZHAO X G, CAI M. Influence of specimen height-to-width ratio on the strainburst characteristics of Tianhu granite under true-triaxial unloading conditions [J]. Canadian Geotechnical Journal, 2014, 52(7): 890–902. DOI: https://doi.org/10.1139/cgj-2014-0355.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Projects(41877272, 51974359) supported by the National Natural Science Foundation of China

Contributors

GONG Feng-qiang provided the concept, developed the overarching research goal, and led the research activity planning and execution. GONG Feng-qiang also made great contribution to the improvement of manuscript after the initial draft finished. SU You-qiang conducted the experiments, analyzed the test data, and wrote the initial draft of the manuscript. LUO Song offers some valuable suggestions for the contents of the manuscript and edited the language of the manuscript. LIU Zhi-xiang reviewed and edited the manuscript. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

SU You-qiang, GONG Feng-qiang, LUO Song, and LIU Zhi-xiang declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Su, Yq., Gong, Fq., Luo, S. et al. Experimental study on energy storage and dissipation characteristics of granite under two-dimensional compression with constant confining pressure. J. Cent. South Univ. 28, 848–865 (2021). https://doi.org/10.1007/s11771-021-4649-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4649-2

Key words

- rock mechanics

- two-dimensional compression

- linear energy storage law

- single cyclic loading-unloading

- height-to-width ratio