Abstract

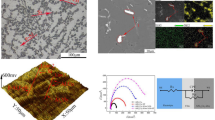

The effects of rare earth ytterbium (Yb) addition and hot extrusion on the microstructure and corrosion behavior of as-cast ADC12 were studied by optical microscopy (OM), scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS) and X-ray diffraction (XRD). The experimental results demonstrate that both the Si phase and β-Al5FeSi phase in the alloy with 0.9 wt% Yb have been remarkably refined, and the Al3Yb intermetallic compound has also been obtained. The Si, β-Al5FeSi, and rare earth phases are further refined in the alloy at 0.9 wt% Yb and hot extrusion. The results of the immersion corrosion tests and electrochemical experiments show that the corrosion current density (8.56 µA/cm2) of the alloy with 0.9 wt% Yb addition and hot extrusion is 50.6% lower than the untreated alloy (17.33 µA/cm2), and the polarization resistance (9252 Ω·cm2) was 71.3% higher than the untreated alloy (2654 Ω·cm2). The corrosion in the cathode phase in the micro-battery was refined to varying degrees attributable to the addition of Yb and hot extrusion, where the cathode reaction in the corrosion process caused a decrease of the corrosion rate.

摘要

通过光学显微镜(OM)、扫描电子显微镜(SEM)、能谱仪(EDS)和 X 射线衍射(XRD)研究了稀土 Yb 的添加及热挤压对铸态 ADC12 合金的微观组织及腐蚀性为的影响. 结果表明, 添加 0.9% Yb 后, 合金中的 Si 相和 β-Al5 FeSi 相都得到了显著的细化, 并且还获得了 Al3 Yb 金属间化合物. 热挤压后的稀土合金的 Si 相、 β-Al5 FeSi 相以及稀土相进一步细化. 浸泡腐蚀实验和电化学实验发现, 热挤压后稀土铝合金的腐蚀电流密度(8.56 µA/cm2)比未处理合金的(17.33 µA/cm2)低50.6%, 极化电阻(9252 Ω·cm2)比未处理合金的(2654 Ω·cm2)高71.3%. 热挤压及稀土 Yb 的添加在不同程度上细化了腐蚀微电池中的阴极相, 从而使得腐蚀过程中的阴极反应速率降低.

Similar content being viewed by others

References

ZHANG Xue-song, CHEN Yong-jun, HU Jun-ling. Recent advances in the development of aerospace materials [J]. Progress in Aerospace Sciences, 2018, 97: 22–34. DOI: https://doi.org/10.1016/j.paerosci.2018.01.001.

DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys [J]. Materials & Design, 2014, 56: 862–871. DOI: https://doi.org/10.1016/j.matdes.2013.12.002.

STARKE E A Jr, STALEY J T. Application of modern aluminum alloys to aircraft [J]. Progress in Aerospace Sciences, 1996, 32(2, 3): 131–172. DOI: https://doi.org/10.1016/0376-0421(95)00004-6.

YE Hai-zhi. An overview of the development of Al-Si-alloy based material for engine applications [J]. Journal of Materials Engineering and Performance, 2003, 12(3): 288–297. DOI: https://doi.org/10.1361/105994903770343132.

PUDOVIKOV E I. Parts from aluminum alloys (body of the wheelpair reduction gearbox) [J]. Metal Science & Heat Treatment, 2000, 42: 196–200. DOI: https://doi.org/10.1007/BF02469849.

GAYLE F W, GOODWAY M. Precipitation hardening in the first aerospace aluminum alloy: The wright flyer crankcase [J]. Science, 1994, 266(5187): 1015–1017. DOI: https://doi.org/10.1126/science.266.5187.1015.

SLATTERY B E, PERRY T, EDRISY A. Microstructural evolution of a eutectic Al-Si engine subjected to severe running conditions [J]. Materials Science and Engineering A, 2009, 512(1, 2): 76–81. DOI: https://doi.org/10.1016/j.msea.2009.01.025.

MILLER W S, ZHUANG L, BOTTEMA J, WITTEBROOD A J, de SMET P, HASZLER A, VIEREGGE A. Recent development in aluminium alloys for the automotive industry [J]. Materials Science and Engineering A, 2000, 280(1): 37–49. DOI: https://doi.org/10.1016/s0921-5093(99)00653-x.

OKAYASU M, OHKURA Y, TAKEUCHI S, TAKASU S, OHFUJI H, SHIRAISHI T. A study of the mechanical properties of an Al-Si-Cu alloy (ADC12) produced by various casting processes [J]. Materials Science and Engineering A, 2012, 543: 185–192. DOI: https://doi.org/10.1016/j.msea.2012.02.073.

LIAO Wen-bo, LIU Xin-yu, LIU Sheng-dan, ZHANG Xin-ming. Effect of exfoliation corrosion on mechanical properties of 7055 aluminum alloy sheet [J]. Journal of Central South University, 2012, 43(6): 2137–2141. DOI: https://doi.org/10.1109/INTMAG.2005.1463725.

PAN J, LEE S P, YOSHIDA M, SASAKI G, FUTAMA N, FUJII T, FUKUNAGA H. Effect of whisker surface treatment on the strength of Al18B4O33/Al alloy composites [J]. Advanced Composite Materials, 2001, 10(4): 299–307. DOI: https://doi.org/10.1163/156855101753415328.

YUE T M, YAN L J, CHAN C P, DONG C F, MAN H C, PANG G K H. Excimer laser surface treatment of aluminum alloy AA7075 to improve corrosion resistance [J]. Surface and Coatings Technology, 2004, 179(2, 3): 158–164. DOI: https://doi.org/10.1016/s0257-8972(03)00850-8.

WAGNER L. Mechanical surface treatments on titanium, aluminum and magnesium alloys [J]. Materials Science and Engineering A, 1999, 263(2): 210–216. DOI: https://doi.org/10.1016/s0921-5093(98)01168-x.

LI Qing-lin, XIA Tian-dong, LAN Ye-feng, ZHAO Wen-jun, FAN Lu, LI Peng-fei. Effect of rare earth cerium addition on the microstructure and tensile properties of hypereutectic Al-20%Si alloy [J]. Journal of Alloys & Compounds, 2013, 562(1): 25–32. DOI: https://doi.org/10.1016/j.jallcom.2013.02.016.

JOY-YII S L, KURNIAWAN D. Effect of rare earth addition on microstructure and mechanical properties of Al-Si alloys: An overview [J]. Advanced Materials Research, 2013, 845: 27–30. DOI: https://doi.org/10.4028/www.scientific.net/AMR.845.27.

TZENG Y C, JIAN S Y. Effects of the addition of trace amounts of Sc on the microstructure and mechanical properties of Al-11.6Si alloys [J]. Materials Science and Engineering A, 2018, 723: 22–28. DOI: https://doi.org/10.1016/j.msea.2018.03.016.

JIN P, XIAO B, WANG Q. Effect of hot extrusion on interfacial microstructure and tensile properties of SiCp/2009Al composites fabricated at different hot pressing temperatures [J]. Journal of Materials Science & Technology, 2011, 27(6): 40–46. DOI: https://doi.org/10.1016/S1005-0302(11)60101-1.

HSIANG S H, KUO J L. An investigation on the hot extrusion process of magnesium alloy sheet [J]. Journal of Materials Processing Technology, 2003, 140(1–3): 6–12. DOI: https://doi.org/10.1016/s0924-0136(03)00693-9.

YU J, ZHAO G, CHEN L. Investigation of interface evolution, microstructure and mechanical properties of solid-state bonding seams in hot extrusion process of aluminum alloy profiles [J]. Journal of Materials Processing Technology, 2016, 230: 153–166. DOI: https://doi.org/10.1016/j.jmatprotec.2015.11.020.

DING Ke, LIAO Heng-cheng, JIN Qiu-min, TANG Yun. Effect of hot extrusion on mechanical properties and microstructure of near eutectic Al-12.0%Si-0.2%Mg alloy [J]. Materials Science and Engineering A, 2010, 527(26): 6887–6892. DOI: https://doi.org/10.1016/j.msea.2010.07.068.

LIANG J M, GUO X Q, ZHENG Y F. Effect of extrusion temperature on microstructural evolution and intergranule bonding of Al-7Si-0.3Mg (wt%) alloy rods produced by extrusion of granule compacts [J]. Journal of Materials Processing Technology, 2016, 232: 78–89. DOI: https://doi.org/10.1016/j.jmatprotec.2016.01.030.

WEI Zhi-fan, LEI Yu-shun, YAN Hong, XU Xi-hao, HE Jia-jia. Microstructure and mechanical properties of A356 alloy with Y addition processed by hot extrusion [J]. Journal of Rare Earths, 2019, 37(6): 659–667. DOI: https://doi.org/10.1016/j.jre.2018.11.008.

HAMIDREZA G, MOHD H I, NORHAYATI A. Effect of hot extrusion on microstructural evolution and tensile properties of Al-15%Mg2Si-xGd in-situ composites [J]. Journal of Alloys and Compounds, 2018, 751: 370–390. DOI: https://doi.org/10.1016/j.jallcom.2018.04.131.

ARRABAL R, MINGO B, PARDO A, MOHEDANO M, MATYKINA E, MERINO M C, RIVAS A. Microstructure and corrosion behaviour of A356 aluminium alloy modified with Nd [J]. Materials and Corrosion, 2015, 66(6): 535–541. DOI: https://doi.org/10.1002/maco.201407674.

ZOU Yong-cheng, YAN Hong, YU Bao-biao, HU Zhi. Effect of rare earth Yb on microstructure and corrosion resistance of ADC12 aluminum alloy [J]. Intermetallics, 2019, 110: 106–114. DOI: https://doi.org/10.1016/j.intermet.2019.106487.

YIN Zheng, CHEN Yang, YAN Hong, ZHOU Guo-hua, WU Xiao-quan, HU Zhi. Effects of the second phases on corrosion resistance of AZ91-xGd alloys treated with ultrasonic vibration [J]. Journal of Alloys and Compounds, 2019, 783: 877–885. DOI: https://doi.org/10.1016/j.jallcom.2019.01.002.

QI Xing, SUN Bin, ZHANG Xiao-yan, QI Wen-juan, WANG Chao, SONG Ren-guo. Effects of cathodic polarization on SCC behavior of AA7003 under various aging treatments [J]. Journal of Central South University, 2018, 25(10): 2299–2308. DOI: https://doi.org/10.1007/s11771-018-3914-5.

NIU Hao-yi, CAO Fang-fang, DENG Kun-kun, NIE Kai-bo. Microstructure and corrosion behavior of the as-extruded Mg-4Zn-2Gd-0.5Ca alloy [J]. Acta Metallurgica Sinica (English Letters), 2020, 33: 362–374. DOI: https://doi.org/10.1007/s40195-019-00984-2.

HUANG Xin, YAN Hong. Effect of trace La addition on the microstructure and mechanical property of as-cast ADC12 Al-alloy [J]. Journal of Wuhan University of Technology-Mater, Sci. Ed, 2013, 28(1): 202–205. DOI: https://doi.org/10.1007/s11595-013-0665-x.

QIAN M, CAO P, EASTON M A, MCDONALD S D, STJOHN D H. An analytical model for constitutional supercooling-driven grain formation and grain size prediction [J]. Acta Materialia, 2010, 58(9): 3262–3270. DOI: https://doi.org/10.1016/j.actamat.2010.01.052.

YU Bao-biao, YAN Hong, ZHU Jian-bin., LIU Jian-long, LI Huo-gen, NIE Qiao. Effects of La on microstructure and corrosion behavior of AlSi5Cu1Mg alloy [J]. Acta Metallurgica Sinica (English Letters), 2018, 32(4): 443–451. DOI: https://doi.org/10.1007/s40195-018-0782-9.

SACCONE A, CACCIAMANI G, MACCIÒ D, BORZONE G, FERRO R. Contribution to the study of the alloys and intermetallic compounds of aluminium with the rare-earth metals [J]. Intermetallics, 1998, 6(3): 201–215. DOI: https://doi.org/10.1016/s0966-9795(97)00066-6.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51965040) supported by the National Natural Science Foundation of China; Project(20181BAB206026) supported by the Natural Science Foundation of Jiangxi Province, China

Rights and permissions

About this article

Cite this article

He, Jj., Yan, H., Zou, Yc. et al. Microstructure and corrosion behavior of as-cast ADC12 alloy with rare earth Yb addition and hot extrusion. J. Cent. South Univ. 27, 1654–1665 (2020). https://doi.org/10.1007/s11771-020-4397-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4397-8