Abstract

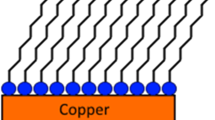

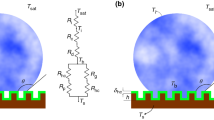

Condensation is an important regime of heat transfer which has wide applications in different industries such as power plants, heating, ventilating and air conditioning, and refrigeration. Condensation occurs in two different modes including filmwise (FWC) and dropwise (DWC) condensation. DWC occurring on hydrophobic and superhydrophobic surfaces has a much higher heat transfer capacity than FWC. Therefore, wide investigations have been done to produce DWC in recent years. Superhydrophobic surfaces have micro/nano structures with low surface energy. In this study, a two-step electrodeposition process is used to produce micro/nano structures on copper specimens. The surface energy of specimens is reduced by a self-assembled monolayer using ethanol and 1-octadecanethiol solution. The results show that there is an optimum condition for electrodeposition parameters. For example, a surface prepared by 2000 s step time has 5 times greater heat transfer than FWC while a surface with 4000 s step time has nearly the same heat transfer as FWC. The surfaces of the fabricated specimens are examined using XRD and SEM analyses. The SEM analyses of the surfaces show that there are some micro-structures on the surfaces and the surface porosities are reduced by increasing the second step electrodeposition time.

摘要

冷凝是一种重要的传热机制, 在发电厂、采暖、通风、空调、制冷等行业有着广泛的应用。冷凝以两种不同的模式发生, 包括膜状冷凝(FWC)和滴状冷凝(DWC)。在疏水和超疏水表面上发生的滴状冷凝热传递容量远高于膜状冷凝。因此, 近年来对滴状冷凝进行了广泛的研究。超疏水表面具有低表面能的微纳米结构。在本研究中, 采用两步电沉积法在铜表面沉积出微/纳米结构。用乙醇和1-十八硫醇溶液自组装单分子层来降低试样的表面能。结果表明, 电沉积工艺具有最佳的条件。例如, 当第二步电沉积时间为2000 s 时, 滴状冷凝的热传递量是膜状冷凝的5 倍, 而当第二步电沉积时间为4000 s 时, 滴状冷凝(DWC)与膜状冷凝(FWC)热传递几乎相同。使用XRD 和SEM 分析检测制备的试样表面。SEM 分析显示, 在试样表面上存在一些微结构, 通过延长第二步电沉积时间, 可以降低表面孔隙率。

Similar content being viewed by others

References

SIAVASHI M, JAMALI M. Optimal selection of annulus radius ratio to enhance heat transfer with minimum entropy generation in developing laminar forced convection of water-Al2O3 nanofluid flow [J]. Journal of Central South University, 2017, 24(8): 1850–1865.

MAHMOODI M, KANDELOUSI S. Kerosene-alumina nanofluid flow and heat transfer for cooling application [J]. Journal of Central South University, 2016, 23(4): 983–990.

LIU Fan-han, XU Jian-xin, WANG Hua. Numerical method and model for calculating thermal storage time for an annular tube with phase change material [J]. Journal of Central South University, 2017, 24(1): 217–226.

NI Ming-long, CHEN Ya-ping, DONG Cong, WU Jia-feng. Numerical simulation of heat transfer and flow of cooling air in triangular wavy fin channels [J]. Journal of Central South University, 2014, 21(7): 2759–2765.

WANG H, TANG L, WU X, DAI W, QIU Y. Fabrication and anti-frosting performance of super hydrophobic coating based on modified nano-sized calcium carbonate and ordinary polyacrylate [J]. Applied Surface Science, 2007, 253(22): 8818–8824.

LATTHE S S, SUDHAGAR P, DEVADOSS A, KUMAR A M, LIU S, TERASHIMA C, NAKATA K, FUJISHIMA A. A mechanically bendable superhydrophobic steel surface with self-cleaning and corrosion-resistant properties [J]. Journal of Materials Chemistry A, 2015, 3(27): 14263–14271.

ALI H M, BRIGGS A. A semi-empirical model for free-convection condensation on horizontal pin-fin tubes [J]. International Journal of Heat and Mass Transfer, 2015, 81: 157–166.

ALI H M, BRIGGS A. Condensation of ethylene glycol on pin-fin tubes: Effect of circumferential pin spacing and thickness [J]. Applied Thermal Engineering, 2012, 49: 9–13.

ALI H M, QASIM M Z. Free convection condensation of steam on horizontal wire wrapped tubes: Effect of wire thermal conductivity, pitch and diameter [J]. Applied Thermal Engineering, 2015, 90: 207–214.

ALI H, KAMRAN M S, ALI H M, FARUKH F, IMRAN S, WANG H S. Marangoni condensation of steam-ethanol mixtures on a horizontal low-finned tube [J]. Applied Thermal Engineering, 2017, 117: 366–375.

SCHMIDT E, SCHURIG W, SELLSCHOPP W. Versuche über die kondensation von wasserdampf in film-und tropfenform [J]. Technische Mechanik und Thermodynamik, 1930, 1(2): 53–63. (in German)

WANG S, YU X, LIANG C, ZHANG Y. Enhanced condensation heat transfer in air-conditioner heat exchanger using superhydrophobic foils [J]. Applied Thermal Engineering, 2018, 137: 758–766.

QUAN X, CHEN S, LI J, CHENG P. Enhanced dropwise condensation by oil infused nano-grass coatings on outer surface of a horizontal copper tube [J]. International Communications in Heat and Mass Transfer, 2018, 91: 11–16.

HOENIG S H, BONNER R W. Dropwise condensation on superhydrophobic microporous wick structures [J]. Journal of Heat Transfer, 2018, 140(7): 071501.

WEN R, LI Q, WU J, WU G, WANG W, CHEN Y, MA X, ZHAO D, YANG R. Hydrophobic copper nanowires for enhancing condensation heat transfer [J]. Nano Energy, 2017, 33: 177–183.

TALESH BAHRAMI H R, AHMADI B, SAFFARI H. Optimal condition for fabricating superhydrophobic copper surfaces with controlled oxidation and modification processes [J]. Materials Letters, 2017, 189(Supplement C): 62–65.

SAFFARI H, SOHRABI B, NOORI M R, TALESH BAHRAMI H R. Optimal condition for fabricating superhydrophobic aluminum surfaces with controlled anodizing processes [J]. Applied Surface Science, 2018, 435: 1322–1328.

TALESH BAHRAMI H R, AHMADI B, SAFFARI H. Preparing superhydrophobic copper surfaces with rose petal or lotus leaf property using a simple etching approach [J]. Materials Research Express, 2017, 4(5): 055014.

HE G, LU S, XU W, YU J, WU B, CUI S. Fabrication of durable superhydrophobic electrodeposited tin surfaces with tremella-like structure on copper substrate [J]. Surface and Coatings Technology, 2017, 309: 590–599.

QING Y, YANG C, YU Z, ZHANG Z, HU Q, LIU C. Large-area fabrication of superhydrophobic zinc surface with reversible wettability switching and anticorrosion [J]. Journal of the Electrochemical Society, 2016, 163(8): D385–D391.

XU L, GUO Y, LIAO Q, ZHANG J, XU D. Morphological control of ZnO nanostructures by electrodeposition [J]. The Journal of Physical Chemistry B, 2005, 109(28): 13519–13522.

TALESH BAHRAMI H R, SAFFARI H. Theoretical study of stable dropwise condensation on an inclined micro/nano-structured tube [J]. International Journal of Refrigeration, 2017, 75(Supplement C): 141–154.

ELIAS J, TENA-ZAERA R, Lévy-Clément C. Electrodeposition of ZnO nanowires with controlled dimensions for photovoltaic applications: Role of buffer layer [J]. Thin Solid Films, 2007, 515(24): 8553–8557.

BAHRAMI H R T, SAFFARI H, BAHRAMI H R T, SAFFARI H. Mathematical modeling and numerical simulation of dropwise condensation on an inclined circular tube [J]. Journal of Aerospace Technology and Management, 2017, 9(4): 476–488.

PATIL C M, SANTHANAM K S V, KANDLIKAR S G. Development of a two-step electrodeposition process for enhancing pool boiling [J]. International Journal of Heat and Mass Transfer, 2014, 79: 989–1001.

GAO J, LU L S, SUN J W, LIU X K, TANG B. Enhanced boiling performance of a nanoporous copper surface by electrodeposition and heat treatment [J]. Heat and Mass Transfer, 2017, 53(3): 947–958.

ALBERTSON C E. Boiling heat transfer surface and method: US4018264A [P]. 1977-04-19.

KIM J H. Enhancement of pool boiling heat transfer using thermally-conductive microporous coating techniques [D]. Arlington: University of Texas, 2006.

El-Genk M S, ALI A F. Enhanced nucleate boiling on copper micro-porous surfaces [J]. International Journal of Multiphase Flow, 2010, 36(10): 780–792.

SAMOYLOV A V, MIRSKY V M, HAO Q, SWART C, SHIRSHOV Y M, WOLFBEIS O S. Nanometer-thick SPPR sensor for gaseous HCl [J]. Sensors and Actuators B: Chemical, 2005, 106(1): 369–372.

KEDZIERSKI M A, III J L W. Design and machining of copper specimens with micro holes for accurate heat transfer measurements [J]. Experimental Heat Transfer, 1993, 6(4): 329–344.

O’NEILL G A, WESTWATER J W. Dropwise condensation of steam on electroplated silver surfaces [J]. International Journal of Heat and Mass Transfer, 1984, 27(9): 1539–1549.

GUO Y, WU H, LI Y, JIANG C, WANG Q, WANG T. Facile fabrication of superhydrophobic Cu(OH)2 nanorod and CuO nanosheet arrays on copper surface [J]. Journal of Nanoscience and Nanotechnology, 2012, 12(3): 1952–1956.

SABLOWSKI J, UNZ S, BECKMANN M. Dropwise condensation on advanced functional surfaces-theory and experimental set-up [J]. Chemical Engineering & Technology, 2017, 40(11): 1966–1974.

KIM S, KIM K J. Dropwise condensation modeling suitable for superhydrophobic surfaces [J]. Journal of Heat Transfer, 2011, 133(8): 081502.

XI J, FENG L, JIANG L. A general approach for fabrication of superhydrophobic and superamphiphobic surfaces [J]. Applied Physics Letters, 2008, 92(5): 053102.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Talesh Bahrami, H.R., Azizi, A. & Saffari, H. Dropwise condensation heat transfer enhancement on surfaces micro/nano structured by a two-step electrodeposition process. J. Cent. South Univ. 26, 1065–1076 (2019). https://doi.org/10.1007/s11771-019-4071-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4071-1