Abstract

The ongoing need for better fuel economy and lower exhaust pollution of vehicles has increased the employment of electric power steering (EPS) in automotives. Optimal design of EPS for a product family reduces the development and fabrication costs significantly. In this paper, the TOPSIS method along with the NSGA-II is employed to find an optimum family of EPS for an automotive platform. A multi-objective optimization problem is defined considering road feel, steering portability, RMS of Ackerman error, and product family penalty function (PFPF) as the conflicting objective functions. The results for the single objective optimization problems and the ones for the multi-objective optimization problem, as well as two suggested trade-off design points are presented, compared and discussed. For the two suggested points, performance at one objective function is deteriorated by about 1%, while the commonality is increased by 20%–40%, which shows the effectiveness of the proposed method in first finding the non-dominated design points and then selecting the trade-off among the obtained points. The results indicate that the obtained trade-off points have superior performance within the product family with maximum number of common parts.

摘要

对更好的燃油经济性和降低汽车尾气污染的持续需求增加了电动转向(EPS)在汽车中的应用。 产品系列的(EPS)优化设计可大大降低开发和制造成本。本文采用 TOPSIS 和 NSGA-II 相结合的方法, 寻找汽车平台 EPS 的最优系列, 提出了一个多目标优化问题.该问题将道路感、转向便携性、Ackerman 误差的均方根和产品系列罚函数作为相互制约的目标函数。给出了单目标优化问题和多目标优化问题 的结果, 并提出了两个折衷设计点, 进行了比较和讨论。对于这两个折衷设计点, 一个目标函数的性 能下降了约 1%, 而共性增加了 20%~40%, 说明了该方法在首先找到非主导设计点, 然后在得到的点 之间进行权衡的有效性。结果表明, 所得到的折衷点在公共部件数量最大的产品系列中具有较好的性 能。

Similar content being viewed by others

References

PARK J, SIMPSON T W. Toward an activity-based costing system for product families and product platforms in the early stages of development [J]. International Journal of Production Research, 2008, 46(1): 99–130. DOI: https://doi.org/10.1080/00207540600825240.

MARION T J J, THEVENOT H J J, SIMPSON T W W. A cost-based methodology for evaluating product platform commonality sourcing decisions with two examples [J]. International Journal of Production Research, 2007, 45(22): 5285–5308. DOI: https://doi.org/10.1080/00207540600710970.

SIMPSON T W, SIDDIQUE Z, JIAO J R. Platform-based product family development [C]//Product Platform and Product Family Design. Boston, MA, US: Springer. DOI: https://doi.org/10.1007/0-387-29197-0_1.

MEYER M H, LEHNERD A P. The power of product platforms: Building value and cost leadership [M]. New York,: Simon and Schuster, 1997: 39.

SIMPSON T T W T, SIDDIQUE Z, JIAO R J R. Product platform and product family design, methods and applications [M]. New York: Springer, 2006.

CHANG T S, WARD A C. Design-in-modularity with conceptual robustness. Advances in Design Automation [J]. ASME, 1995, 82(1): 493–500.

FELLINI R, KOKKOLARAS M, MICHELENA N, PAPALAMBROS P, PEREZ-DUARTE A, SAITOU K, FENYES P. A sensitivity-based commonality strategy for family products of mild variation, with application to automotive body structures [J]. Structural and Multidisciplinary Optimization, 2004, 27(1, 2): 89–96. DOI: https://doi.org/10.1007/s00158-003-0356-x.

SIMPSON T W, MAIER J R A, MISTREE F. A product platform concept exploration method for product family design [C]//ASME Design Theory and Methodology. Las Vegas: ASME, 1999: DTM8761.

MESSAC A, MARTINEZ M P M P, SIMPSON T W T W. Introduction of a product family penalty function using physical programming [J]. Journal of Mechanical Design, 2002, 124(2): 164–172. DOI: https://doi.org/10.1115/1.1467602.

AKUNDI S, SIMPSON T W, REED P M. Multi-objective design optimization for product platform and product family design using genetic algorithms [C]//31st Design Automation Conference, Parts A and B, vol. 2005. Long Beach, CA,: ASME, 2005: 999–1008. DOI: https://doi.org/10.1115/DETC2005-84905.

SIMPSON T W, D’SOUZA B S. Assessing variable levels of platform commonality within a product family using a multiobjective genetic algorithm [J]. Concurrent Engineering, 2004, 12(2): 119–129. DOI: https://doi.org/10.1177/1063293X04044383.

CETIN O L, SAITOU K. Decomposition-based assembly synthesis for structural modularity [J]. Journal of Mechanical Design, 2004, 126(2): 234. DOI: https://doi.org/10.1115/1.1666890.

MESSAC A, MARTINEZ M P, SIMPSON T W. Effective product family design using physical programming [J]. Engineering Optimization, 2002, 34(3): 245–261. DOI: https://doi.org/10.1080/030521502117462010.

SRINIVAS N, DEB K. Muiltiobjective optimization using nondominated sorting in genetic algorithms [J]. Evolutionary Computation, 1994, 2(3): 221–248. DOI: https://doi.org/10.1162/evco.1994.2.3.221.

DEB K, PRATAP A, AGARWAL S, MEYARIVAN T. A fast and elitist multiobjective genetic algorithm: NSGA-II [J]. IEEE Transactions on Evolutionary Computation, 2002, 6(2): 182–197. DOI: https://doi.org/10.1109/4235.996017.

MOZAFFARI A, VAJEDI M, CHEHRESAZ M, AZAD N L. Multi-objective component sizing of a power-split plug-in hybrid electric vehicle powertrain using Pareto-based natural optimization machines [J]. Engineering Optimization, 2016, 48(3): 361–379. DOI: https://doi.org/10.1080/0305215X.2015.1012075.

KIM Y G, LEE J. Fatigue design of a cellular phone folder using regression model-based multi-objective optimization [J]. Engineering Optimization, 2016, 48(8): 1275–1295. DOI: https://doi.org/10.1080/0305215X.2015.1099641.

ZHAO An, LAI Zhou-nian, WU Peng, CAO Lin-lin, WU Da-zhuan. Multi-objective optimization of a low specific speed centrifugal pump using an evolutionary algorithm [J]. Engineering Optimization, 2016, 48(7): 1251–1274. DOI: https://doi.org/10.1080/0305215X.2015.1104987.

KHALKHALI A. Best compromising crashworthiness design of automotive S-rail using TOPSIS and modified NSGAII [J]. Journal of Central South University, 2015, 22(1): 121–133. DOI: https://doi.org/10.1007/s11771-015-2502-1.

HWANG C L, YOON K. Methods for multiple attribute decision making [M]. Berlin, Heidelberg: Springer, 1981. DOI: https://doi.org/10.1007/978-3-642-48318-93.

SHOJAEEFARD M H, KHALKHALI A, FAGHIHIAN H, DAHMARDEH M. Optimal platform design using non-dominated sorting genetic algorithm II and technique for order of preference by similarity to ideal solution; application to automotive suspension system [J]. Engineering Optimization, 2018, 50(3): 471–482. DOI: https://doi.org/10.1080/0305215X.2017.1324853.

DENG Y W, LIU H W, ZHAO X H, E J Q, CHEN J M. Effects of cold start control strategy on cold start performance of the diesel engine based on a comprehensive preheat diesel engine model [J]. Applied Energy, 2018, 210: 279–287. DOI: https://doi.org/10.1016/j.apenergy.2017.10.093.

E J Q, ZHANG Z Q, TU Z F, ZUO W, HU W Y, HAN D D, JIN Y. Effect analysis on flow and boiling heat transfer performance of cooling water-jacket of bearing in the gasoline engine turbocharger [J]. Applied Thermal Engineering, 2018, 130: 754–766. DOI: https://doi.org/10.1016/j.applthermaleng.2017.11.070.

E J Q, HAN D D, DENG Y W, ZUO W, QIAN C, WU G, PENG Q G, ZHANG Z Q. Performance enhancement of a baffle-cut heat exchanger of exhaust gas recirculation [J]. Applied Thermal Engineering, 2018, 134: 86–94. DOI: https://doi.org/10.1016/j.applthermaleng.2018.01.109.

E J Q, ZUO Q S, LIU H L, LI Y, GONG J K. Endpoint forecasting on composite regeneration by coupling cerium-based additive and microwave for diesel particulate filter [J]. Journal of Central South University, 2016, 23(8): 2118–2128. DOI: https://doi.org/10.1007/s11771-016-3268-9.

ZUO Q S, E J Q, GONG J K, ZHANG D M, CHEN T, JIA Ghai. Performance evaluation on field synergy and composite regeneration by coupling cerium-based additive and microwave for a diesel particulate filter [J]. Journal of Central South University, 2014, 21(12): 4599–4606. DOI: https://doi.org/10.1007/s11771-014-2466-6.

LIAO Y G, DU H I. Cosimulation of multi-body-based vehicle dynamics and an electric power steering control system [J]. Journal of Multi-Body Dynamics, 2001, 215(3): 141–151. DOI: https://doi.org/10.1243/1464419011544420.

ZHAO W Z, SHI G B, LIN Y, NIE H. Tracking performance of electric power steering system based on the mixed h2/h∞ strategy [J]. Chinese Journal of Mechanical Engineering 2011, 24(4): 584–590.

ZANG H Q, GENG J. Effects and solution of electric power steering system on vehicle handling stability [J]. Journal of Computational Information Systems, 2012, 8(1): 65–72.

ZHAO W Z, ZHAO T, LI Y J, WANG C Y, ZHANG Z Q, DUAN T T. Integration optimization of novel electric power steering system based on quality engineering theory [J]. Journal of Central South University, 2013, 20(6): 1519–1526. DOI: https://doi.org/10.1007/s11771-013-1643-3.

ZHAO W, WANG C, SUN P, LIU S. Primary studies on integration optimization of differential steering of electric vehicle with motorized wheels based on quality engineering [J]. Science China Technological Sciences, 2011, 54(11): 3047–3053. DOI: https://doi.org/10.1007/s11431-011-4565-z.

JAZAR R N. Vehicle dynamics: Theory and application [M]. Boston, MA: Springer, 2008. DOI: https://doi.org/10.1007/978-0387-74244-1.

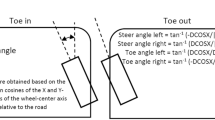

RAHMANI HANZAKI A, RAO P V M, SAHA S K. Kinematic and sensitivity analysis and optimization of planar rack-and-pinion steering linkages [J]. Mechanism and Machine Theory, 2009, 44(1): 42–56. DOI: https://doi.org/10.1016/j.mechmachtheory.2008.02.014.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khalkhali, A., Shojaeefard, M.H., Dahmardeh, M. et al. Optimal design and applicability of electric power steering system for automotive platform. J. Cent. South Univ. 26, 839–851 (2019). https://doi.org/10.1007/s11771-019-4053-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4053-3