Abstract

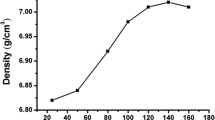

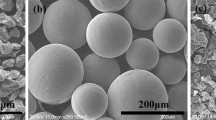

The phenomena of die wall lubricated warm compaction of non-lubricant admixed iron powders were researched, and its mechanism of densification was discussed. Water atomized powder obtained from the Wuhan Iron and Steel Corporation was used. With compacting and sintering, compared with cold compaction, the density of warm compacted samples increases by 0.07 – 0.22 g/cm3 at the same pressed pressure. The maximum achievable green density of warm compacted samples is 7.12 g/cm3 at 120 °C, and the maximum sintered density is 7.18 g/cm3 at 80 °C. Compared with cold compaction, the ejection force of warm compaction is smaller; the maximum discrepancy is about 7 kN. The warm compacted mechanism of densification of iron powders can be obtained; heating the powder contributes to improving plastic deformation of powder particles, and accelerating the mutual filling and rearrangement of powder particles.

Similar content being viewed by others

References

HUANG Pei-yun. The Principle of Powder Metallurgy (2rd) [M]. Beijing: Metallurgical Industry Press, 2004. 377–396. (in Chinese)

YE Tu-ming, YI Jian-hong, PENG Yuan-dong, et al. New technique of increasing the compact density of powder metallurgy parts[J]. Powder Metallurgy Industry, 2003, 13(6): 32–36. (in Chinese)

GUO Shi-ju. Technical progress in warm compaction in powder metallurgy[J]. Powder Metallurgy Industry, 2003, 13(2): 4–8. (in Chinese)

Capus J, Pickering S, Weaver A. Hoeganaes offers higher density at lower cost[J]. Metal Powder Report, 1994, 49(7/8): 22–24.

Rutz H G, Hanejko F G. High density processing of high performance ferrous materials[J]. The International of Powder Metallurgy, 1995, 31(1): 9–17.

St-Laurent S, Chagnon F. Key parameters for warm compaction of high density materials[A]. Cadle T M, Narasimhan K S. Advances in Powder Metallurgy & Particulate Materials[C]. Priceton: MPIF, 1996.

Enström U, Johansson B. Experience with warm compaction of densmix powders in the production of complex parts[A]. Kosuge K, Nagai H. Proceedings of 2000 Powder Metallurgy World Congress[C]. Kyoto: The Japan Society of Powder Metallurgy, 2000.

Sawayama T, Sato M, Seki Y, et al. High performance P/M materials by high density process[A]. Kosuge K, Nagai H. Proceedings of 2000 Powder Metallurgy World Congress[C]. Kyoto: The Japan Society of Powder Metallurgy, 2000.

Chagnon F, St-Laurent S. Optimizing powder mix formulation and processing conditions for warm compaction[A]. Kosuge K, Nagai H. Proceedings of 2000 Powder Metallurgy World Congress[C]. Kyoto: The Japan Society of Powder Metallurgy, 2000.

Li Y Y, Ngai T L, Zhang D T, et al. Effect of die wall lubrication on warm compaction powder metallurgy[J]. Journal of Materials Processing Technology, 2002, 129: 354–358.

Chagnon F, Gélinas C, Trudel Y. Development of high density materials for P/M applications [A]. Chaman L. Advances in Powder Metallurgy & Particulate Materials[C]. Priceton: MPIF, 1994.

Ngal T L, Chen W P, Xiao Z Y, et al. Die wall lubricated warm compaction of iron-based powder metallurgy material[J]. Trans Nonferrous Met Soc China, 2002, 12(6): 1095–1098.

Lemieux P, Thomas Y, Mongenon P E, et al. Benefits of die wall lubrication for powder compaction[A]. Lawcock R, Wright M. Advances in Powder Metallurgy & Particulate Materials[C]. Princeton: MPIF, 2003.

Kondoh M, Okajima H. High density powder compation using die wall lubrication[A]. Arnold V. Advances in Powder Metallurgy & Particulate Materials[C]. Priceton: MPIF, 2002.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (715-012-0060) supported by the National High Technology Research and Development Program of China

Rights and permissions

About this article

Cite this article

Ye, Tm., Yi, Jh., Chen, Sj. et al. Die wall lubricated warm compaction behavior of non-lubricant admixed iron powders. J Cent. South Univ. Technol. 12, 653–656 (2005). https://doi.org/10.1007/s11771-005-0063-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0063-4