Abstract

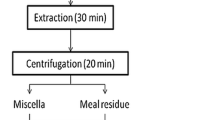

An aqueous extraction process was developed consisting of aqueous contact with dehulled yellow mustard flour to recover protein followed by dissolution of the released emulsion in dimethylformamide (DMF) or isopropyl alcohol (IPA) to recover the released oil in the form of single-phase oil–solvent miscellae suitable for industrial applications. Only some 38 ± 3 % of the oil in the yellow mustard emulsion was extracted using DMF even at high weight ratios since DMF is widely miscible with water, preventing separation of the oil from the emulsion. A ternary phase diagram of DMF/oil/water was prepared and confirmed the limited solubility of the oil in DMF in the presence of water. The use of 31:1 IPA:oil weight ratio could effectively recover over 94 % of the oil in the emulsion; however, multiple-stage treatment of the emulsion was proven to be more efficient with lower volumes of IPA required to achieve high oil extraction yields. The results suggest that the optimal conditions for multiple-stage process were four stages using 2:1 IPA:oil weight ratio, with 96 ± 1 % oil recovery from the emulsion.

Similar content being viewed by others

References

Bell JM, Rakow G, Downey RK (2000) Comparisons of amino acid and protein levels in oil-extracted seeds of Brassica and Sinapis species, with observations on environmental effects. Can J Anim Sci 80:169–174

Rosenthal A, Pyle DL, Niranjan K (1996) Aqueous and enzymatic processes for edible oil extraction. Enzyme Microb Technol 19:402–420

Tzen JTC, Cao YZ, Laurent P, Ratnayake C, Huang AHC (1993) Lipids, proteins, and structure of seed oil bodies from diverse species. Plant Physiol 101:267–276

Chabrand RM, Glatz CE (2009) Destabilization of the emulsion formed during the enzyme-assisted aqueous extraction of oil from soybean flour. Enzyme Microb Technol 45:28–35

Chabrand RM, Kim HJ, Zhang C, Glatz CE, Jung S (2008) Destabilization of the emulsion formed during aqueous extraction of soybean oil. J Am Oil Chem Soc 85:383–390

De Moura JMLN, Campbell K, Mahfuz A, Jung S, Glatz CE, Johnson L (2008) Enzyme-assisted aqueous extraction of oil and protein from soybeans and cream de-emulsification. J Am Oil Chem Soc 85:985–995

Jung S, Maurer D, Johnson LA (2009) Factors affecting emulsion stability and quality of oil recovered from enzyme-assisted aqueous extraction of soybeans. Bioresour Technol 100:5340–5347

Lamsal BP, Johnson LA (2007) Separating oil from aqueous extraction fractions of soybean. J Am Oil Chem Soc 84:785–792

Wu J, Johnson LA, Jung S (2009) Demulsification of oil-rich emulsion from enzyme-assisted aqueous extraction of extruded soybean flakes. Bioresour Technol 100:527–533

Zhang SB, Wang Z, Xu SY (2007) Downstream processes for aqueous enzymatic extraction of rapeseed oil and protein hydrolysates. J Am Oil Chem Soc 84:693–700

Li NN, Hucal T, Cahn RP (1977) Demulsification process. US Patent 4,001,109

McClements DJ (2004) Food emulsions: principles, practice, and techniques, 2nd edn. CRC Press, Boca Raton

Menon WB, Wasan DT (1985) Demulsification. In: Becher P (ed) Encyclopedia of emulsion technology. Marcel Dekker, New York, pp 1–75

Tabtabaei S, Diosady LL (2012) The isolation of yellow mustard oil using water and cyclic ethers. J Am Oil Chem Soc 89:935–945

Appelqvist LÃ (1971) Composition of seeds of cruciferous oil crops. J Am Oil Chem Soc 48:851–859

Mehta GD, Fraser MD (1985) A novel extraction process for separating ethanol and water. Ind Eng Chem Process Des Dev 24:556–560

Lajara JR (1989) Solvent extraction of oil from oilseeds: the real basics. In: Erickson DR (ed) Proceedings of the World Conference on edible fats and oils processing: basic principles and modern practices. AOCS Press, Champaign, pp 49–55

Johnson LA, Lusas EW (1983) Comparison of alternative solvents for oils extraction. J Am Oil Chem Soc 60:229–242

Lusas EW, Gregory SR (1996) New solvents and extractors. In: Koseoglu SS, Rhee KC, Wilson RF (eds) Proceedings of the World Conference on oilseed and edible oils processing. AOCS Press, New York, pp 204–219

Zhang F, Rhee KC, Koseoglu SS (2002) Isopropyl alcohol extraction of cottonseed collets: efficiency and performance. J Food Lipids 9:147–160

Acknowledgments

This project was funded by the Natural Sciences and Engineering Research Council of Canada through its strategic grants program.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Tabtabaei, S., Ataya Pulido, V.M. & Diosady, L.L. Destabilization of Yellow Mustard Emulsion Using Organic Solvents. J Am Oil Chem Soc 90, 707–716 (2013). https://doi.org/10.1007/s11746-013-2202-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-013-2202-7