Abstract

The aim of this study was to investigate levels of polychlorinated biphenyls (marker and dioxin-like congeners), polycyclic aromatic hydrocarbons (EPA 15 + 1), polybrominated diphenyl ethers (14 predominant congeners) and pesticides (74 compounds) in various cold-pressed vegetable oils. Poppy seed oil, rapeseed oil, sesame seed oil, pumpkinseed oil, hempseed oil, linaire oil, borage oil and evening star oil were investigated. Results of this study revealed that concentrations of PCBs, PBDEs and PAHs were low in majority of the investigated samples. However, high concentrations of organophosphorus insecticides were found. Chlorpyrifos methyl and pirimiphos methyl were the pesticide residues most commonly found in the studied oils. Concentration of 15 + 1 EPA PAHs was within the 17.85–37.16 μg kg−1 range, concentration of (marker) PCBs varied from 127 to 24,882 pg g−1, dioxin-like TEQ values were below 0.1 pg TEQ g−1. Concentration of PBDEs was below LOQ in most cases.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polycyclic aromatic hydrocarbons (PAHs), polychlorinated biphenyls (PCBs), polybrominated biphenyl ethers (PBDEs) and pesticides are regarded as hazardous chemical contaminants of food. These groups of substances are not uniform, they include numerous compounds differing in their chemical structure. PCBs and PBDEs each include 209 so-called congeners possessing different chlorination/bromination level and/or substituent position on the molecule [1, 2]. PAHs comprise a wide range of chemicals build of at least two connected aromatic rings [3]. Pesticides form a very diversified group of chemicals belonging to more than 100 different chemical classes.

Due to widespread use of pesticides in agriculture, their residues in food are practically unavoidable. It is estimated that more than 1,000 active substances are or were in the past used for plant/crop protection [4]. Residues of PAHs, PCBs and PBDEs in food are mainly related to the environment, into which these chemicals are brought mainly by some human activities. However, small amounts of PCBs and relatively high amounts of PAHs may originate as by-products of natural processes: PAHs are predominantly formed by incomplete combustion of organic materials [3], whereas small amounts of PCBs might be formed during combustion of materials containing carbon and chlorine.

Maximum permitted levels of selected food chemical contaminants including PAHs (B[a]P) and dioxin-like PCBs are specified in the 1881/2006 European Commission (EC) Regulation [5]. Maximum permitted levels of pesticide residues in food products are specified in the 299/2008 EC Regulation [6]. On the other hand, neither non-dioxin-like PCB nor PBDE maximum levels have been defined within the European Union (EU) food policy. However, according to the 2006/794 EU Recommendation [7], levels of non-dioxin-like PCBs should be monitored in foodstuffs in order to determine PCB back-ground levels.

Polybrominated biphenyl ethers are a relatively new group of food chemical contaminants. PBDEs are manufactured as flame retarding agents to be added to numerous consumer goods, including textiles, synthetic fibers, plastics [8]. Due to similarities between chemical structure/physical properties/chemical properties of PCBs and PBDEs, some concerns regarding circulation of these latter substances in the environment are still arising. Even if PCBs were banned from the industrial production in 1970s, they are still commonly found within the environment. Several studies indicate that PBDEs may also be widely distributed throughout the environment since residues of these substances have been found in vast majority of tested environmental/food samples [9, 10].

The aim of this study was to investigate concentrations of selected PAHs, PCBs, PBDEs and pesticides in several cold-pressed vegetable oils used as flavoring agents or regarded as possessing extraordinary nutritional value. Pumpkin seed oil, linaire oil, poppy-seed oil, hempseed oil, borage oil, sesame seed oil, evening star oil and rape seed oil were investigated. Literature data on presence of the mentioned contaminants in the above listed oils are scarce. Concentrations of the following contaminants were determined:

-

12 dioxin-like PCBs listed in the 1881/2006 EC Regulation (congeners # 77, 81, 105, 114, 118, 123, 126, 156, 157, 167, 169 and 189) and Benzo(a)-pyrene.

-

6 non-dioxin-like PCBs listed in the 2006/794 EC Recommendation (congeners # 28, 52, 101, 138, 153 and 180).

-

15 U.S. EPA Priority PAHs (Naf, Acy, Ace, Fluo, Phe, Ant, Flua, Pyr, B[a]A, Chry, B[b]F, B[k]F, DB[ah]A, B[ghi]P, IndP) [11].

-

14 PBDEs (congeners # 17, 28, 47, 66, 71, 85, 99, 100, 138, 153, 154, 183, 190 and 209).

-

74 pesticides belonging to various chemical classes (those that are most frequently identified in food products).

Materials and Methods

Vegetable Oil Samples

Cold-pressed oils available on the retail market were used. Poppy seed oil, rapeseed oil, sesame seed oil, pumpkinseed oil, hempseed oil, linaire oil, borage oil and evening star oil were taken into the investigation. Three samples of different oil brands were mixed up in equal proportions to prepare a composite (laboratory) oil sample of the given type. Only a single sample of hempseed oil was obtained and used for analyses. Due to high number of sophisticated and time consuming determinations composite samples were used to assess the presence of investigated compounds in studied types of cold pressed vegetable oils.

Laboratory made spiked samples used for the assessment of the analytical method performance were made by the addition of known amount of analytical standards to vegetable oil samples without detectable amounts of the studied compounds. PCB-, PBDE- and pesticide-spiked samples were prepared in the same manner as reported in our previous paper [12, 14]. PAH-spiked samples were prepared by the addition of the known amount of standard dissolved in cyclohexane. Spiking concentrations of the studied compounds are given in Tables 1, 1, 3.

Chemicals

Only Pestiscan-grade solvents were used in this study. Acetonitrile, dimethylsulfoxide, hexane, cyclohexane, dichloromethane, methanol, and ethyl acetate were supplied by Lab Scan (Dublin, Ireland). Analytical-grade anhydrous silver nitrate, sodium sulfate and sulfuric acid (96%) were obtained from POCh (Gliwice, Poland). Silica gel 60 (0.063–200 mm) and Florisil 60 were obtained from Merck (Darmstadt, Germany). Florisil was heated at 500 °C for 4 h before use. Silver nitrate impregnated silica gel (10%) was prepared by mixing silica gel with silver nitrate water solution and drying the obtained mixture at 130 °C in the dark. Silver nitrate impregnated silica gel was stored in the dark before use. Sulfuric acid impregnated silica gel was prepared by mixing concentrated sulfuric acid 96% with silica gel, while basic (KOH impregnated) silica gel was prepared by mixing a methanol solution of KOH with silica gel and drying the obtained mixture for 30 min at 130 °C. Sodium sulfate was heated for 4 h at 450 °C before use and stored in an desiccator over a silica-based moisture absorber. Laboratory-made semi-permeable membranes were prepared from a 80 mm thick low-density polyethylene (LDPE) walls of 250 × 25 mm lay flat tubing obtained from Artfolie (Bielsko-Biala, Poland). LDPE was extracted for 7 days with n-hexane before use. High purity (>97%) native PCB standards (IUPAC 28, 43, 52, 77, 81, 101, 105, 114, 118, 123, 126, 138, 146, 153, 156, 157, 167, 169, 180, 189, 194, and 209) and PAH standards (Naf, Acy, Ace, Fluo, Phe, Ant, Flua, Pyr, B[a]A, Chry, B[b]F, B[k]F, B[a]P, DB[ah]A, B[ghi]P, IndP) were supplied by Dr Ehrenstorfer (Augsburg, Germany). 13C12-labelled standards (IUPAC 77, 81, 105, 114, 118, 123, 126, 156, 157, 167, 169, 189) and native polybrominated biphenyl ethers standards (IUPAC 17, 28, 47, 66, 71, 85, 99, 100, 138, 153, 154, 183, 190, 209) were obtained from Cambridge Isotope Laboratories (Andover, MA, USA). Silica gel Discovery DSC-Si SPE cartridges (5 g) and Superclean Envicarb-PSA cartridges (1 g) were obtained from Supelco (Bellefonte, PA, USA).

Determination of Pesticides

Determinations were conducted on a Thermo-Finnigan Trace GC Ultra gas chromatograph (Austin, TX, USA) connected via a heated transfer line with a Polaris Q low-resolution ion-trap mass spectrometer (Austin, TX, USA) was equipped with a Programmable Temperature Vaporizer (PTV)-based injector and TriPlus Autosampler (Austin, TX, USA). All separations were made on 60 m × 0.25 mm × 0.25 mm Zb-5 MS 5%-Phenyl-Arylene-fused-silica capillary column (Phenomenex, Torrance, CA, USA) connected via a Vu2 Union connector (Restek, Bellefonte, PA, USA) to a 5 m × 0.25 mm × 0.25 mm guard column/retention gap (Restek). Helium was used as a carrier gas at a constant flow rates of 1 ml min−1. The GC’s oven program was as follows: initial 40 °C (1 min hold)— 180°C at 25 °C min−1—215°C at 2°C min−1 (1 min hold)— 255°C at 5°C min−1 (0.5 min hold)— final 280°C at 25°C min−1 (20 min hold). Spectrometer mass calibration was tuned against perfluorotributylamine (FC-43) in electron-impact positive ionization mode according to the manufacturer’s recommendations. Pesticide residues in oil samples were determined using slightly modified method proposed in our previous study [12]. Briefly, oil samples were extracted with acetonitrile : water mixture (1:5), cleaned up on a double layer SPE cartridges, evaporated to dryness and analyzed with gas chromatography ion trap mass spectrometry. Neither recovery of pesticides from the analyzed spiked samples, relative recovery standard deviations, nor limits of quantification for individual pesticides were significantly different than those reported previously. Recovery of the analyzed pesticides from the fortified oil samples was within the 70–120% range, recovery relative standard deviation was below 20% in most cases. Pesticide recovery data are given in Table 1. Detailed analytical parameters including ionization and data acquisition methods used for pesticide determination were given previously [12].

Determination of PAHs

Determinations of PAHs were conducted on a Shimadzu (Duisburg, Germany) Prominence chromatographic system equipped with an auto injector, degasser and a FLD detector was used in this study. Analysis were performed on a Pinnacle II PAH (Restek), 4 μm, 150 mm × 3.2 mm column operated at a flow rate of 300 μl min−1. Following gradient mobile phase (A: Acetonitrile B: water) was used for separations: initial A:B 50:50—5–20 min A:B 75:25—20–30 min A:B 78:22—30–60 min A:B 100:0—60–70 min A:B 50:50. Samples were introduced via a 10-μl loop type auto injector. PAHs were determined according to modified method proposed by Larsson et al. [13]. Briefly, 10 g of oil sample was placed in a separatory funnel, dissolved in 20 ml of cyclohexane and triple-extracted with 10-ml portions of dimethylsulfoxide (DMSO). Combined DMSO extracts were mixed with 60 ml of water and re-extracted with 50 ml of petroleum ether. Petroleum phase was evaporated to dryness with rotary evaporator operated at 30 °C. Subsequently dry residues were quantitatively transferred with a 3 × 1 ml portions of cyclohexane on the SPE silica gel (5 g) cartridge, pre-conditioned with 20 ml of cyclohexane. The cartridge was first washed with 15 ml of cyclohexane and with 10 ml of dichloromethane:cyclohexane mixture (5:95 V/V). PAHs were eluted with 15 ml of dichloromethane:cyclohexane mixture (50:50 V/V). The PAH fraction was rotary evaporated to dryness, re-dissolved in 500 μl of acetonitrile and submitted to HPLC analysis.

Determination of PCBs and PBDEs

Determinations were performed on the same instrument/configuration as used for pesticide residue analysis. Helium was used as the carrier gas at a constant flow rate of 1 ml min−1 in PCB analysis and programmed flow from 1.5 to 2.5 ml min−1 for PBDE analysis. The GC’s oven program in PCB analysis was as follows: initial 100 °C (3 min hold)— 180 °C at 10 °C min−1—200 °C at 1.7 °C min−1 (2 min hold)—240 °C at 1.8 °C min−1 (8 min hold)—final 280 °C at 50 °C min−1 (15 min hold), and for PBDE initial 80–180 °C at 3 °C min−1 (20 min hold)—300 °C at 5OC min−1 (21 min hold)—310 °C at 10 °C min−1 (41 min hold). To obtain the required sensitivity, the multiplier voltage was manually set to 1700 V, and automatic gain control to 15. Detailed analytical parameters including ionization and data acquisition methods used for PCB determination were given previously [14].

In the case of PBDE analysis the mass spectrometer was operated in the MS/MS mode. Helium was used as the ion-trap dumping gas (flow 1.7 ml min−1 and 2.5 ml min−1 for BDE 209) analysis were conducted at 31 eV electron energy and 250 mA emission current. [M-79Br81Br]+ ions were used as an MS/MS precursor ion for all studied PBDEs. [M-(279Br)81Br]+, [M-79Br(281Br)]+, [M-(279Br)81Br-2CH2]+ and [M-79Br(281Br)-2CH2]+ peaks were monitored in MS/MS spectra for quantitative purposes. Determination of BDE 209 required separate ion optic lens optimization against m/z 614 of FC43 mass spectra. Ion source temperature was set to 300 °C, isolation time 20 ms, excitation time 30 ms. Excitation energies required for sufficient CID yield were in the 3.3–5.5 V range for tri- to deca- BDE. Xcalibur version 1.2 software was used for data acquisition and analysis.

Analytical method used to determine PCBs and PBDEs was based on procedures described in our previous study [13] with some major modifications based on results of Hanxia et al. [15]. Briefly, samples were spiked with 13C12 PCB recovery standards, dialyzed through LDPE semi-permeable membrane and cleaned with gel permeation chromatography as described previously. Subsequent cleanup was performed on a multilayer silica-gel-based chromatography column connected in series with short silver nitrate silica gel column (1 g 10% w/w). GPC-cleaned-up samples (after solvent exchange to n-hexane) were loaded on the columns and eluted with 30 ml of dichloromethane:n-hexane mixture (2:98 V/V). Subsequently only second silver nitrate column was eluted with 25 ml of a dichloromethane:n-hexane mixture (50:50 V/V). First fraction contained PCBs and the second PBDEs. PCB fraction was subsequently fractionated using short (10 × 100 mm) Florisil column containing 2 g of activated Florisil. PCB fraction was evaporated to dryness and quantitatively transferred on the top of Florisil column with 2 × 1 ml portions of n-hexane. Florisil column was first eluted with 30 ml of dichloromethane:n-hexane mixture (0.5:99.5) (fraction containing ortho-substituted PCBs) and then with 25 ml of 50% dichloromethane : n-hexane mixture (fraction containing non-ortho substituted PCBs). PCB fractions were evaporated to dryness, spiked with injection standards, re-dissolved in 1 ml of n-hexane and submitted for GC/MS/MS analysis. GC/MS method used for PCB analysis was based on those reported previously [14] with modification of sample introduction technique. Inject-ions were made into cold (60 °C) PTV injector baffle liner. A total of 40 μl of purified and concentrated extract was introduced into the PTV injector (10 μl s−1) working in the solvent split mode (with split valve set 200 ml min−1). After 1 min, the split valve was closed and the injector temperature was ramped to 280 °C and held for 2 min. Next, the injector temperature was increased to 320 °C (10 min hold) and the split valve was opened with flow rate set to 100 ml min−1 to eliminate any residual high boiling contaminants out of the injector system.

The PBDE fraction was re-dissolved in n-hexane, spiked with injection standards and concentrated to an approximate volume of 100 μl under a gentle stream of nitrogen. The sample was introduced into GC/MS using the standard purged-splitless injection technique into a straight glass liner (2 mm ID). Injector was operated at 320 °C and helium pressure of 480 kPa was applied. A total of 6 μl of purified and concentrated extract was introduced into the PTV injector (10 μl s−1). Splitless time was set to 2 min. The carrier gas flow rate (not including initial ramp due to purged injection) was programmed starting from 1.5 ml min−1 (50 min hold), to 2.5 ml min−1 (40 min hold) and subsequently to 1.5 ml min−1.

Data Analysis

Results are given as a mean value of two parallel determinations (±one standard deviation, if given) of the composite laboratory sample (prepared from three different oils mixed at equal proportions). TEQs for individual PCBs were calculated using WHO 1998 published factors [16]. For each sample total TEQ value was calculated as the sum of individual TEQs of all dl-PCBs. Lower-bound, medium-bound, and upper-bound results have been reported in line with Commission Regulation 1883/2006 [17]. Data in Table 8 were also calculated using the revised TEF 2005 values [18].

Results and Discussion

There is scarcely any literature data concerning the presence of chemical contaminants in cold-pressed vegetable oils. The present study revealed that pesticides, PAHs, PCBs and PBDEs were present in the cold pressed oils at varying concentration levels.

Pesticides

Concentrations of pesticide residues found in the studied cold-pressed vegetable oil samples are given in Table 4. The results are quite surprising. Five out of 8 of the composite oil samples studied showed detectable amounts of pesticide residues. Mostly organophosphorus insecticide residues (Pirimiphos methyl, Chlorpyrifos methyl, DDVP) were found. DDT isomers and Trifluralin herbicide were determined in pumpkinseed oil. DDT is on the Stockholm persistent organic pollutant (POP) list and its presence in oil samples is most likely related to the environmental POPs background level. The highest total concentration of pesticides was found in the Linaire oil sample, with pirimiphos methyl concentration at the 1.170 mg kg−1 level. European Union legislation does not recognize any maximum residue levels (MRLs) for the determined compound/investigated oil combinations. Nevertheless, the concentrations are very high when compared to MRLs defined for oil seeds (0.05 mg kg−1 for sum of DDT isomers, 0.05 mg kg−1 for pirimiphos methyl, 0.01 mg kg−1 for DDVP, 0.1 mg kg−1 for trifluralin, 0.05 mg kg−1 for chlorpyrifos methyl). Those MRLs were exceeded in the majority of the tested samples. A typical chromatogram of a vegetable oil sample is shown in Fig. 1. Pesticide residue levels found in the oil samples are probably among the most unexpected results. Organophosphorus (OPPs) insecticides are commonly used in agriculture for protection of oily plants. Most probably this fact is responsible for the presence of those compounds in cold-pressed vegetable oils. Most of OPPs are fat-soluble and might be easily stored in oil seeds. What’s more, fats—as energy reserves for oil seeds—may be not subject to metabolic pathways that could affect OPPs. This hypothesis might also explain the very high concentrations of OPPs determined in the samples. Persistence of organophosphorus insecticides in vegetable oils was also reported previously [19]. Due to specific flavors and other characteristics of cold-pressed vegetable oils, they are not as widely consumed as refined vegetable oils (except for virgin olive oil). Refined vegetable oils probably have significantly lower concentrations of various contaminants due to high temperature and/or pressure treatment. Those supposition is also confirmed by several literature data [20–22]. According to data reported by oil producers, organophosphorus insecticides are commonly found in vegetable oils at relatively high concentrations. Results of this study seem to confirm that data [21, 23].

PAHs

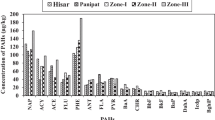

Recovery of the studied PAHs, recovery relative standard deviation and operating parameters of the detector are given in Table 2. Data on PAHs contents found in the studied cold-pressed vegetable oil samples are given in Table 5. Average concentration of all studied PAHs (15 + 1) was 25.33 ± 7.17 μg kg−1. The highest concentration was found in cold-pressed pumpkinseed oil (37.16 μg kg−1) and the lowest one – in cold-pressed rapeseed oil samples (17.85 μg kg−1). Naphthalene, phenanthrene and pyrene were the most abundant PAHs among all studied ones. Average profile of PAHs in the studied samples is shown in Fig. 2. High concentrations of anthracene were also found in linaire seed and rapeseed oils. Maximum residue level of benzo[a]pirene in vegetable oils according to the 1881/2006 EC Regulation is 2 μg kg−1. None of the samples exceeded that level: we found B[a]P concentrations within the 0.02–1.25 μg kg−1 range, the highest one in cold-pressed sesame oil, and the lowest one in cold-pressed rapeseed oil. Typical chromatogram showing the PAH vegetable oil PAH fraction is shown in Fig. 3. The PAH contents found in the investigated samples were negligible as compared to the literature data. According to that data, a high concentration of polycyclic aromatic hydrocarbons in vegetable oils is mainly attributable to environment contamination, but may also be attributed to the process of oil production [24–26]. Oil seeds are subjected to a drying process prior to oil extraction. If some membrane-less drying technique based on combustion gases as the source of heat is used, a high contaminations of vegetable oils with PAHs may result. Drying methods commonly used nowadays are based rather on fluid beds that ensure a high quality of the final product. PAH contents found in the samples do not differ significantly from literature data reported for common vegetable oils such as sesame oil, olive oil, or rapeseed oil [3, 26–30]. Low molecular PAHs are also reported as the most abundant compounds in vegetable oils.

PCBs and PBDEs

Recovery, recovery relative standard deviation, limits of quantification and ionization parameters for the PBDE congeners are given in Table 3.

PCB and PBDE contents found in the studied cold-pressed vegetable oil samples are given in Tables 6 and 7.

Concentration of the marker PCBs (SUM6) in analyzed oil samples varied from 127 to 24,882 pg g−1 (the pumpkinseed oil sample and the borage oil sample, respectively). Lower chlorinated congeners dominated the non-dioxin-like PCB fraction. PCB 28, 52 and 101 were the most abundant congeners.

Concentration of dioxin-like PCB congeners was generally low in the analyzed vegetable oil samples. The highest one was found for PCB 118 congener, while the most toxic PCB 126 congener was not found in majority of the analyzed samples at a concentration above LOQ (i.e. ≥0.19 pg g−1). The concentrations of twelve dioxin-like congeners were within the 9.7–128 pg g−1 range (minimum for the hempseed oil sample, maximum for the borage oil sample).

Typical chromatogram showing marker-PCB fraction extracted from an oil sample is shown in Fig. 4. Average profile of the PCB fraction within the oil samples is shown in Fig. 5.

PCB TEQ values determined for the studied samples are shown in Table 8. PCBs 105, 114, 118 and 126 had the highest average contribution to PCB TEQ. Average total contribution of those four congeners accounted to more that 80% of the total PCB TEQ. TEQ results calculated for 2005 TEFs were generally lower than those calculated for 1998 TEFs. This is influenced mainly by decreased TEF values for mono-ortho-PCB in the 2005 TEF scheme.

Majority of the investigated PBDE congeners in the oil samples were below LOQ. BDE 47, 77 and 99 were the most abundant and subsequently the most frequently congeners found. The highest total concentration of 14 PBDEs was (19.3 pg g−1) found in the linaire oil sample. PCBs and PBDEs in oil may be attributable mainly to environmental contamination. However, such contaminants are typical for high-fat food products of animal origin rather than for plant materials. Most of the studied PBDEs were generally not found in the investigated samples. Mostly lower brominated BDEs were found at very low concentrations. Those data are in concordance with data reported by other researchers [31–33]. However, Akutsu et al. reported high concentrations of decaBDE in vegetable oils. This study does not confirm those reports. Blanco et al. suggested that air concentrations of decaBDE could strongly affect analytical results and cause high values for procedural blanks [34].

Absolute concentration of PCBs in the samples were much higher that those found for PBDEs. Lower chlorinated PCBs were the most abundant, in concordance with results of Skribic et al. and Yagüe et al. [35] who reported high contribution of lower chlorinated biphenyls in vegetable oil samples. The profile of PCBs found in the analyzed samples shows a high contribution of low chlorinated congeners. Most probably such a profile is typical for products of plant origin. Concentrations of the most abundant 6 marker PCBs determined in this study were in the low ng g−1 range (except for one sample) and were similar to those reported by Skribic et al. and Marti et al.. An exceptionally high concentration was determined for the borage oil sample (~25,000 pg g−1). High differences in PCB concentration might be caused by regional PCB contamination, but in such a case, the PCB profile would differ, which was not the case in this study. The most probable cause of such a high variability are differences in atmospheric PCB absorption and/or mechanism of PCB deposition in plant fatty tissues. Different pathways of contaminations have already been reported for several plant varieties [36, 37]. Concentrations of dioxin-like PCBs in the studied samples expressed as dioxin toxicity equivalent were very low, significantly below 0.1 pg TEQ g−1 (even when expressed as the upper bound result). The difference between upper-bound and lower-bound results for many of the analyzed samples did not meet the requirements of the 1883/2006 EC Regulation [5] i.e. below 20% for TEQ ≥ 1 pg g−1 and within the 25–40% range for TEQ ≤ 1 pg g−1. This is caused by very low TEQ concentrations determined in the analyzed samples. Concentration of the most toxic PCB 126 congener (with the highest assigned TEF value) was below LOQ.

The aim of this study was to investigate incidence of various groups of chemical food contaminants in cold-pressed vegetable oils. The environment was found to be the main source of contamination of cold-pressed oils with PCBs, PBDEs and also PAHs, whereas the presence of most of the pesticides may be traced back to agricultural practices. Results of this study indicate that various groups of chemical food contaminants may be found in cold-pressed vegetable oils at relatively high concentrations. As it was mentioned earlier, literature data on presence of pesticides, PAHs, PCBs and PBDEs in cold-pressed oils are scarce, therefore it is impossible to assess health risk related to consumption of such oils. The main purpose of this study was to assess the necessity of monitoring residues of several classes of chemicals in cold-pressed vegetable oils. The presented data clearly expose the problem of cold-pressed oil chemical contamination (mainly by pesticides) rather than giving precise information on the levels of those substances in the studied group of products. Authors believe that further research on residues of various chemical compounds—especially pesticides—in cold-pressed vegetable oils is necessary.

Abbreviations

- Ace:

-

Acenaphtene

- Acy:

-

Acenapthylene

- Ant:

-

Anthracene

- B[a]A:

-

Benzo(a)anthracene

- B[a]P:

-

Benzo(a)pyrene

- B[b]F:

-

Benzo(b)fluoranthene

- B[ghi]P:

-

Benzo[g,h,i]perylene

- B[k]F:

-

Benzo(k)fluoranthene

- Chry:

-

Chrysenes

- DB[ah]A:

-

Dibenz[a,h]anthracene

- DMSO:

-

Dimethylsulfoxide

- EPA:

-

Environmental protection agency

- Flua:

-

Fluoranthene

- Fluo:

-

Fluorene

- IndP:

-

Indeno[1,2,3-cd]pyrene

- LDPE:

-

Low density polyethylene

- LOQ:

-

Limit of quantification

- Naf:

-

Naphtalene

- PAHs:

-

Polycyclic aromatic hydrocarbon

- PBDEs:

-

Polybrominated diphenyl ether

- PCB:

-

Polychlorinated biphenyl

- Phe:

-

Phenanthrene

- POPs:

-

Persistent organic pollutants

- Pyr:

-

Pyrene

- TEF:

-

2,3,7,8-TCDD dioxin toxicity facor

- TEQ:

-

2,3,7,8-TCDD dioxin toxicity equivalency

References

ATSDR (2000) Agency of toxic substances and disease registry. Toxicological profile for polychlorinated biphenyls (PCBs). U.S. Department of health and human services, Atlanta

ATSDR (2004) Agency of toxic substances and disease registry. Toxicological profile for polybrominated biphenyls and polybrominated diphenyl ethers. U.S. Department of health and human services, Atlanta

ATSDR (1995) Agency of toxic substances and disease registry. Chemical and physical information. In: Toxicological profile for polycyclic aromatic hydrocarbons (PAHs). Atlanta

Tomlin CDS (2003) The pesticide manual—a world compendium, 13th edn. British Crop Protection Council (BPCP), Hampshire

European Commission (2006) Commission Regulation (EC) No. 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs

European Commission (2008) Commission Regulation (EC) No 299/2008 of 11 March 2008 amending Regulation (EC) No 396/2005 on maximum residue levels of pesticides in or on food and feed of plant and animal origin, as regards the implementing powers conferred on the Commission

European Commission (2006) Commission Recommendation of 16 November 2006 on the monitoring of background levels of dioxins, dioxin-like PCBs and non-dioxin-like PCBs in foodstuffs

Rahman F, Langford KH, Scrimshaw MD, Lester JN (2001) Polybrominated diphenyl ether (PBDE) flame retardants. Sci Total Environ 275:1–17

Hale RC, La Guardia MJ, Harvey E, Gaylor MO, Mainor TM (2006) Brominated flame retardant concentrations and trends in abiotic media. Chemosphere 64:181–186

Vonderheidea AP, Muellerb KE, Meijac J, Welshd GL (2008) Polybrominated diphenyl ethers: causes for concern and knowledge gaps regarding environmental distribution. Sci Total Environ 400:425–436

Khadhar S, Higashi T, Hamdi H, Matsuyama S, Charef A (2010) Distribution of 16 EPA-priority polycyclic aromatic hydrocarbons (PAHs) in sludges collected from nine Tunisian wastewater treatment plants. J Hazard Mater 183:98–102

Roszko M, Szymczyk K (2009) Determination of pesticides in cereal products by gas chromatography and ion trap mass spectrometry (GC-ITMS). Anal Chem (Warsaw) 54:1445–1464

Larsson BK, Eriksson AT, Cervenka M (1987) Polycyclic aromatic hydrocarbon in crude and deodorized vegetable oils. J Am Oil Chem Soc 64:365–370

Roszko M, Obiedziński MW, Szymczyk K, Olkowski M (2010) Non-dioxin-like and dioxin-like polychlorinated biphenyls in butter sampled from the Polish retail market. Food Add Cont B 3:126–134

Hanxia L, Quinghau Z, Zongwei C, Yawei W, Guibin J (2006) Separation of polybrominated diphenyl ethers, polychlorinated biphenyls, polychlorinated dibenzo-p-dioxins and dibenzofurans in environmental samples using silica gel and florisil fractionation chromatography. Anal Chim Acta 557:314–320

Van den Berg M, Birnbauml L, Bosveld ATC, Brunstrdm B, Cook P et al (1998) Toxic equivalency factors (TEFs) for PCBs, PCDDs, PCDFs for humans and wildlife. Environ Hlth Perspect 106:775–792

European Commission (2006) Commission Regulation (EC) No. 1883/2006 of 19 December 2006 laying down methods of sampling and analysis for the official control of levels of dioxins and dioxin-like PCBs in certain foodstuffs

Van den Berg M, Birnbaum LS, Denison M, De Vito M, Farland W, Feeley W, Fiedler H, Hakansson H, Hanberg A, Haws L et al (2006) The 2005 World Health Organization reevaluation of human and mammalian toxic equivalency factors for dioxins and dioxin-like compounds. Toxicol Sci 2006(93):223–241

Cabras P, Angioni A, Garau VL, Melis M, Pirisi FM, Karim M, Minelli EV (1997) Persistence of insecticide residues in olives and olive oil. J Agric Food Chem 45:2244–2247

Škrbić B, Đurišić-Mladenović N (2007) Non-dioxin-like PCBs in crops and related products: levels and intakes in Serbia. Food Add Cont 24:652–662

Van Duijn G (2008) Industrial experiences with pesticide removal during edible oil refining. Eur J Lipid Sci Technol 2008(110):982–989

Lacoste F, Soulet B, Arnaud JN, Brenne E, Dauguet S (2005) Food safety in the field of vegetable oils: from monitoring of undesirable compounds to survey plans, conference materials, ISF September 2005. http://iterg.com/IMG/pdf/FL_-_ISF_2005-2.pdf

Duijn Van G, Dekker den G (2010) Unilever food safety assurance system for refined vegetable oils and fats. http://www.webneurologie.com/e-docs/00/04/59/5C/document_article.phtml. Acquired 23 June 2010

Mazumdar S, Redmond C, Sollecito W, Sussman N (1975) An epidemiological study of exposure to coal tar pitch volatiles among coke oven workers. J Air Pollut Control Assoc 25:382–389

Redmond E, Strobino B, Cypress R (1976) Cancer experience among coke by-product workers. Ann NY Acad Sci 271:102–115

IARC (1983) Monographs on the carcinogenic risk of chemicals to humans, vol 32. Polynuclear aromatic compounds. Part 1. Chemical, Environmental and Experimental Data. Lyon

Bonassi S, Merlo F, Puntoni R (1989) Bladder cancer and occupational exposure to polycyclic aromatic hydrocarbons. Int J Cancer 44:648–651

Caporaso N, Hayes RB, Dosemeci M, Hoover R, Ayesh R, Hetzel M, Idle J (1989) Lung cancer risk, occupational exposure, and the debrisoquine metabolic phenotype. Cancer Res 49:3675–3679

Szeszenia-Dąbrowska N, Strzelecka A, Wilczyska U (1991) Zagrożenie substancjami rakotwórczymi w przemyśle. Ocena sytuacji wraz z propozycją systemu informacyjnego. Med Pracy XLII 1:59–64

IH ACG (1998) Threshold limit values for chemical substances and physical agents and biological exposure indices. American Conference of Governmental Industrial Hygienists, Cincinnati

Akutsu K, Takatori S, Nakazawa H, Hayakawa K, Izumi S, Makino T (2008) Dietary intake estimations of polybrominated diphenyl ethers (PBDEs) based on a total diet study in Osaka, Japan. Food Add Cont B 1:58–68

Harrad S, Wijesekera R, Hunter S, Halliwell C, Baker R (2004) Preliminary assessment of UK human dietary and inhalation exposure to polybrominated diphenyl ethers. Environ Sci Technol 38:2345–2350

Marti M, Ortiz X, Gasser M, Marti R, Montana M, Diaz-Ferrero J (2010) Persistent organic pollutants (PCDD/Fs, dioxin-like PCBs, marker PCBs, and PBDEs) in health supplements on the Spanish market. Chemosphere 78:1256–1262

Blanco SL, Vieties JM (2010) Single-run determination of polybrominated diphenyl ethers (PBDEs) di- to deca-brominated in fish meal, fish oil and fish feed by isotope dilution: application of automated sample purification and gas chromatography/ion trap tandem mass spectrometry (GC/ITMS). Anal Chim Acta 672:137–146

Yagüe C, Bayarri S, Conchello P, Lázaro R, Pérez-Arquillué C, Herrera A, Ariño A (2005) Determination of pesticides and PCBs in virgin olive oil by multicolumn solid-phase extraction cleanup followed by GC-NPD/ECD and confirmation by ion-trap GC−MS. J Agric Food Chem 53:5105–5109

Müller JF, McLachlan MS, Hawker DW, Connell DW (1997) Bioconcentration of persistent semivolatile hydrophobic chemicals in the vegetation/atmosphere system. In: Cheremisinoff PN (ed) Ecological issues and environmental impact assessment. Gulf Publishing, Houston, pp 421–442

Huelster A, Mueller JF, Marschner H (1994) Soil-plant transfer of polychlorinated dibenzo-p-dioxins and dibenzofurans to vegetables of the cucumber family (Cucurbitaceae). Environ Sci Technol 28:1110–1115

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Roszko, M., Szterk, A., Szymczyk, K. et al. PAHs, PCBs, PBDEs and Pesticides in Cold-Pressed Vegetable Oils. J Am Oil Chem Soc 89, 389–400 (2012). https://doi.org/10.1007/s11746-011-1926-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-011-1926-5