Abstract

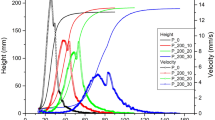

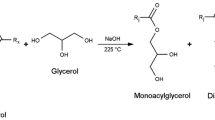

The present study focuses on the use of renewable resource, namely karanja oil for the development of polyurethane foams. The non-edible oil was chemically modified into the diethanolamide by hydroxylation followed by transamidation. The structure of the diethanolamide was confirmed by proton nuclear magnetic resonance spectroscopy, infrared spectroscopy and gas chromatography–mass spectrometry and used as polyol to prepare water-blown polyurethane foams. Polyurethane foams were produced with carbon dioxide as the blowing agent generated by the reaction between excess polymeric MDI with water. Foams were prepared by a hand mixing process which involved blending of the diethanolamide with polypropylene glycol, polymeric MDI, water, catalyst and surfactant. The hydroxyamide content, catalyst nature and molecular weight of polypropylene glycol were varied and the effect on the properties was studied. Foam rise time and other physical properties such as density, compression strength and flexural strength were evaluated. Optical microscopy was used to study the morphology to reveal the closed cell nature and other structure–property relationships.

Similar content being viewed by others

References

Chung L, Xue Y, Hsieh F (2001) Comparative study of physical properties of water blown rigid polyurethane foam extended with commercial soy flours. J Appl Polym Sci 80:10–19

Opera Stefan (2010) Synthesis and properties of polyurethane elastomers with castor oil as crosslinker. J Amer Oil Chem Soc 87:313–320

Narine SS, Kong X, Bouzidi L, Sporns P (2007) Physical properties of polyurethanes produced from polyols from seed oils: elastomers. J Amer Oil Chem Soc 84:55–63

Goldblatt LA, Lyon CK (1963) Fat and oil products in urethane polymers. J Amer Oil Chem Soc 40:157–161

Monteavaro LL, Silva EOD, Costa APO, Samois D, Gerbase EG, Petzold CL (2005) Polyurethane networks from formiated soy polyols: synthesis and mechanical characterization. J Amer Oil Chem Soc 82:365–371

Gruber B, Höfer R, Kluth H, Meffert A (1987) Polyole auf Basis fettchemischer Rohstoffe. Fat Sci Technol 89:147–151

Formo MW (1995) Industrial use of soybean oil. In: Proceedings of the 21st World Congress of the international society of fat research (ISF), The Hague. P. J. Barnes & Associates, Bridgewater, pp 519–527

Hill K (2001) Fats and oils as oleochemical raw materials. J Oleo Sci 50:433–444

Höfer R, Daute P, Grützmacher R, Westfechtel AJ (1997) Oleochemical polyols–a new raw material source for polyurethane coatings and floorings. J Coat Technol 69:65–72

Heidbreder A, Höfer R, Grützmacher R, Westfechtel A, Blewett CW (1999) Oleochemical products as building blocks for polymers. Fett/Lipid 101:418–424

Roloff T, Erkens U, Höfer R, Dusseldorf C (2005) Polyols based on renewable feedstocks–a significant alternative. Urethanes Technol 22:29–33

Ogunniyi DS (2006) Castor oil: A vital industrial raw material. Bioresource Technol 97:1086–1091

Don DA, McSherry WF, Goldblatt LA (1959) Preparations and properties of castor oil urethane foams. J Amer Oil Chem Soc 36:16–20

Mothé G, de Araújo CR (2000) Properties of polyurethane elastomers and composites by thermal analysis. Thermochim Acta 357–358:321–325

Narine SS, Kong X, Bouzidi L, Sporns P (2007) Physical properties of polyurethanes produced from polyols from seed oils: II. Foams. J Amer Oil Chem Soc 84:65–72

Javni I, Zhang W, Petrovic ZJ (2004) Soybean-oil based polyisocyanurate rigid foams. Polym Environ 12:123–129

John J, Bhattacharya M, Turner RB (2002) Characterization of polyurethane foams from soybean oil. J Appl Polym Sci 86:3097–3107

Chian KS, Gan LH (1998) Polyurethane development of rigid foam from palm oil. J Appl Polym Sci 65:509–515

Tuan Noor Maznee TI, Norin ZKS, Ooi TL, Salmiah A, Gan LH (2001) Effect of additives on palm-based polyurethane foams. J Oil Palm Res 13:7–15

Tanaka R, Hirose S, Hatakeyama H (2008) Preparation and characterization of polyurethane foams using a palm oil-based polyol. Bioresource Technol 99:3810–3816

Norin ZKS, Ooi TL, Salmiah A (2004) Effect of triethanolamine on the properties of palm-based flexible polyurethane foams. J Oil Palm Res 16:66–71

Chian KS, Gan LH (1998) Development of a rigid polyurethane foam from palm oil. J Appl Polym Sci 68:509–515

Salamiah A (2001) Palm-based polyol and polyurethanes. MPOB Technol 24:29

Siwayanan P, Ooi TL, Shaari NZK, Ahmad S, Wiese D, Chua MC (1999) Recent development in palm-based polyols. In: Proceedings of the 1999 PORIM International Palm Oil Congress (Oleochemicals). Palm Oil Research Institute, Malaysia, pp 59–64

Guo A, Javni I, Petrovic Z (2000) Rigid polyurethane foams based on soybean oil. J Appl Polym Sci 77:467–473

Khoe TH, Otey F, Frankel EN, Cowan JC (1973) Polyurethane foams from hydroxymethylated fatty diethanolamides. J Amer Oil Chem Soc 50:331–333

Shapiro SH (1968) Commercial nitrogen derivatives of fatty acids. In: Pattison ES (ed) Fatty acids, their industrial applications. Marcel Dekker, New York, pp 77–154

Lyon CK, Garret VH, Frankel EN (1974) Rigid urethane foams from hydroxymethylated castor oil, safflower oil, oleic safflower oil, and polyol esters of castor acids. J Am Oil Chem Soc 51:331–334

Khoe TH, Frankel EN (1976) Rigid polyurethane foams from diethanolamides of carboxylated oils and fatty acids. J Amer Oil Chem Soc 53:17–19

Lee CS, Ooi TL, Chuah CH, Ahmad S (2007) Synthesis of palm oil-based diethanolamides. J Amer Chem Soc 84:945–952

Badri KH, Othman Z, Ahmad SH (2004) Rigid polyurethane foams from oil palm resources. J Mater Sci 39:5541–5542

Meher LC, Naik SN, Das LM (2004) Methanolysis of Pongamia pinnata (karanja) oil for production of biodiesel. J Sci Ind Res 63:913–918

Sharma YC, Singh B (2008) Development of biodiesel from karanja, a tree found in rural India. Fuel 87(8–9):1740–1742

Polyurethane foam Association Inc. (1991) Density. vol 1

Alonso MV, Auad ML, Nutt SR (2006) Modeling the compressive properties of glass fiber reinforced epoxy foam using the analysis of variance approach. Compos Sci Tech 66:2126–2134

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Palanisamy, A., Karuna, M.S.L., Satyavani, T. et al. Development and Characterization of Water-Blown Polyurethane Foams from Diethanolamides of Karanja Oil. J Am Oil Chem Soc 88, 541–549 (2011). https://doi.org/10.1007/s11746-010-1694-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-010-1694-7