Abstract

The article presents a cutting force model for trimming operations of CFRP laminate with diamond abrasive cutters. Those tools are more and more encountered on industrial applications of CFRP trimming, due to their abrasion resistance and their low cost. Contrary to endmills, they consist of a large number of cutting grits, randomly distributed around the tool. To tackle the issue, a continuous model of tool engagement is proposed. Validity of the approach is verified. A mechanical model of cutting forces, adapted to CFRP laminate, is then presented. The evolution of specific cutting coefficient in relation to fibres orientation is investigated through a piecewise constant model. It leads to the proposal of a sine model for the specific cutting coefficients. The simulated forces are in good agreement with the experimental results of cutting tests, carried out in multidirectional CFRP laminate for different fibres orientation and widths of cut. Cutting mechanisms are finally discussed depending on fibres orientation.

Similar content being viewed by others

References

Arola D, Sultan MB, Ramulu M (2002) Finite element modeling of edge trimming fiber reinforced plastics. J Manufac Sc Eng Trans ASME 124(1):32–41

Bhatnagar N, Ramakrishnan N, Kaik NK, Komanduri R (1995) On the machining of fiber reinforced plastic (FRP) composite laminates. Int J Mach Tools Manuf 35(5):701–716

Bonnet C, Benmohammed B, Poulachon G, Rech J, Girard Y (2011) CFRP drilling model: fiber orientation influence on mechanical load and delamination. Adv Mater Res 223:111–121

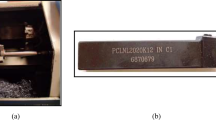

Boudelier A, Ritou M, Garnier S, Furet B (2011) Optimisation of process parameters in cfrp machining with diamond abrasive cutters. Adv Mater Res 223: 774–783. https://doi.org/10.4028/www.scientific.net/AMR.223.774

Boudelier A, Ritou M, Garnier S, Furet B. (2013) Investigation of CFRP machining with diamond abrasive cutters. Revue des Composites et des Matériaux Avancés 23(3):425–436. https://doi.org/10.3166/RCMA.23.425-436

Collingan K, Ramulu M (1999) Edge trimming of graphite/epoxy with diamond abrasive cutters. J Manuf Sci Eng 121:647–655. https://doi.org/10.1115/1.2833089

Dumas C, Boudelier A, Caro S, Garnier S, Ritou M, Furet B (2011) Development of a robotic cell for trimming of composite parts. Mech Indus 12(6):487–494. https://doi.org/10.1051/meca/2011103

Karpat Y, Bahtiyar O, Deger B (2012) Mechanistic force modelling for milling of unidirectionnal carbon fiber reinforced polymer laminates. Int J Mach Tools Manuf 56:79–93. https://doi.org/10.1016/j.ijmachtools.2012.01.001

Malkin SK (1989) Grinding technology: theory and applications of machining with abrasives. Ellis Horwood Limited, Chister

Nayak D, Bhatnagar N, Mahajan P (2005) Machining studies of UD-GFRP composites part 2: finite element analysis. Mach Sci Technol 9(4):503–528

Puw HY, Hocheng H (1998) Chip formation model of cutting fiber-reinforced plastics perpendicular to fiber axis. Trans ASME 120:104–114

Ramulu M (1997) Machining and surface integrity of fibre-reinforced plastic composites. Sadhana 22(3):449–472

Ramkumar J, Malhotra SK, Krishnamurthy R (2004) Effect of workpiece vibration on drilling of GFRP laminates. J Mater Process Technol 152:329–332

Venu Gopala Rao G, Mahajan P, Bhatnagar N (2008) Three-dimensional macro-mechanical finite element model for machining of unidirectional-fiber reinforced polymer composites. Mater Sci Eng 498:142–149

Mohamed Slamani S, Gauthier J-F, Chatelain (2015) A study of the combined effects of machining parameters on cutting force components during high speed robotic trimming of CFRPs. Measurement 59:268–283. https://doi.org/10.1016/j.measurement.2014.09.052

Sheikh-Ahmad J, Tworney J, Kalla D, Lodhia P (2007) Multiple regression and committee neural network force predition models in milling FRP. Mach Sci Technol 11(3):391–412

Sheikh-Ahmad J (2009) Machining of polymer composites, Springer, New York

Teti R (2002) Machining of composite materials. CIRP Ann Manufac Technol 51:611–634

Wang DH, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite. Part I: unidirectional laminate. Int J Mach Tools Manuf 35:1623–1638

Wang DH, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite. Part II: multi-directional laminate. Int J Mach Tools Manuf 35(12):1639–1648

Yuan S, Zhang C, Amin M, Fan H, Liu M (2015) Development of a cutting force prediction model based on brittle fracture for carbon fiber reinforced polymers for rotary ultrasonic drilling. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-015-7269-x

Zhang LC, Zhang HJ, Xiang XM (2001) A force prediction model for cutting unidirectional fibre-reinforced plastics. Mach Sci Technol 5(3):293–305

Acknowledgements

This work was carried out within the context of the working group Manufacturing’21 which gathers 16 French research laboratories. The topics approached are: modelling of the manufacturing processes, virtual machining, and emergence of new manufacturing methods.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boudelier, A., Ritou, M., Garnier, S. et al. Cutting force model for machining of CFRP laminatewith diamond abrasive cutter. Prod. Eng. Res. Devel. 12, 279–287 (2018). https://doi.org/10.1007/s11740-018-0813-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-018-0813-4