Abstract

Quantitative evaluation of the steel corrosion in cables is significant for the safe operation of cable-supported bridges. The magnetic flux (MF) examination shows great potential to detect the corrosion defect, or loss of metallic cross-sectional area (LMA). An LMA defect in steel cables can be measured accurately when it is longer than a certain length. However, for defects in early stage, where the length of corrosion area is short, the MF examination may produce unacceptable error. In this study, the effect of defect length on the MF examination for corrosion detection of bridge cables is investigated through theoretical analysis and model experiments. An original analytical model to quantify the influence of defect length is proposed based on the equivalent magnetic circuit method. Then, MF examination experiments are performed on a series of cable models with different defect lengths and locations to verify the analytical model. Further, parameter study is conducted based on the proposed analytical model to clarify the mechanism of the defect-length effect. The results show that the area loss caused by short corrosion damage will be underestimated if the defect-length effect is neglected, and this effect can be quantified efficiently with the proposed analytical model.

Similar content being viewed by others

References

Mcgogney C H, Landis E N. Magnetic flux leakage for bridge inspection. In: Nondestructive Testing Methods for Civil Infrastructure. New York: American Society of Civil Engineers, 1995, 31–44

Ebeling R M, White B C, Strom R W, Hite J, John E. Assessing Corrosion Damage and Corrosion Progression in Multistrand Anchor Systems in Use at Corps Projects. US Army Corps of Engineers, Report No. ERDC TR-13–3. 2013

Wu X J, Yuan J M, Ben A R. A novel magnetic testing method for the loss of metallic cross-sectional area of bridge cables. International Journal of Applied Electromagnetics and Mechanics, 2012, 39(1): 195–201

Park S, Kim J, Lee C, Lee J J. Magnetic flux leakage sensing-based steel cable NDE technique. Shock and Vibration, 2014, 2014(2): 1–8

Dost Y, Apaydın N, Dedeoğlu E, Mackenzie D K, Akkol O Z. Nondestructive Testing of Bosphorus Bridges. In: Nondestructive Testing of Materials and Structures, Springer, 2013, 819–825

Kitagawa M, Suzuki S, Okuda M. Assessment of cable maintenance technologies for Honshu-Shikoku Bridges. Journal of Bridge Engineering, 2001, 6(6): 418–424

Liu X, Wang Y, Wu B, Gao Z, He C. Design of tunnel magnetoresistive-based circular MFL sensor array for the detection of flaws in steel wire rope. Journal of Sensors, 2016, 2016: 1–8

Reimund V, Pelkner M, Kreutzbruck M, Haueisen J. Sensitivity analysis of the non-destructive evaluation of micro-cracks using GMR sensors. NDT &E International, 2014, 64: 21–29

Weischedel H R, Hoehle H. Quantitative nondestructive in-service evaluation of stay cables of cable-stayed bridges: methods and practical experience. In: Proc. SPIE 2456, Nondestructive Evaluation of Aging Bridges and Highways, 1995

Weischedel H R. Electromagnetic wire rope inspection-resolution is important. Materials Evaluation, 1998, 56(11): 1297–1301

Zhang Q W, Xin R Y, Ji Y F. Corrosion detection for steel wires in bridge cables using magnetic method. In: IABSE Conference Nara 2015, Nara, 2015, Article ID: SS–1

Hamelin M, Kitzinger F. Apparatus for increasing linear resolution of electromagnetic wire rope testing. United States Patent No. 5,565,771

Weischedel H R. Electromagnetic wire rope inspection: signal generation, filtering and computer-aided rope evaluation. In: OIPEEC Technical Meeting on the Non-destructive Testing of Rope, Krakow, Poland, 1999, 91–104

The University Of Reading. Wire Rope Non-destructive Testing-Survey of Instrument Manufacturers. OFFSHORE TECHNOLOGY REPORT-OTO 2000 064. 2000

Jomdecha C, Prateepasen A. Design of modified electromagnetic main-flux for steel wire rope inspection. NDT & E International, 2009, 42(1): 77–83

Xu F, Wang X, Wu H. Inspection method of cable-stayed bridge using magnetic flux leakage detection: principle, sensor design, and signal processing. Journal of Mechanical Science and Technology, 2012, 26 (3): 661–669

Yuan J M. Measurement Methods for Metal Cross-sectional Area of in-service Cables. Dissertation for the Doctoral Degree. Wuhan: Huazhong University of Science & Technology, 2012 (in Chinese)

Geller L B, Rousseau G. Effect of Trapped Wire Rope Debris upon an EM Instrument’s LMA Chart Trace. CANMET INFORMATION CENTER, Research Report No. MRL 90–008 (TR). 1990

Rumiche F, Indacochea J E, Wang M L. Detection and monitoring of corrosion in structural carbon steels using electromagnetic sensors. Journal of Engineering Materials and Technology, 2008, 130(3): 635–644

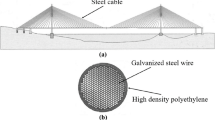

General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Technical Conditions for Hot-Extruding PE Protection High Strength Wire Cable of Cable-Stayed Bridge, GB/T 18365–2001. Beijing: China Standards Press, 2001 (in Chinese)

Christen R, Bergamini A, Motavalli M. Three-dimensional localization of defects in stay cables using magnetic flux leakage methods. Journal of Nondestructive Evaluation, 2003, 22 (3): 93–101

Acknowledgements

The authors are appreciated for the financial support provided by the Ministry of Science and Technology of China (Grant No. SLDRCE14-B-23).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Q., Xin, R. The defect-length effect in corrosion detection with magnetic method for bridge cables. Front. Struct. Civ. Eng. 12, 662–671 (2018). https://doi.org/10.1007/s11709-018-0512-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-018-0512-4