Abstract

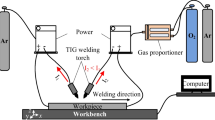

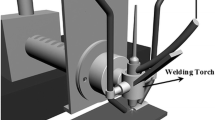

The mechanism of the increasing of A-TIG welding penetration is studied by using the activating flux we developed for stainless steel. The effect of flux on the flow and temperature fields of weld pool is simulated by the PHOENICS software. It shows that without flux, the fluid flow will be outward along the surface of the weld pool and then down, resulting in a flatter weld pool shape. With the flux, the oxygen, which changes the temperature dependence of surface tension grads from a negative value to a positive value, can cause significant changes on the weld penetration. Fluid flow will be inward along the surface of the weld pool toward the center and then down. This fluid flow pattern efficiently transfers heat to the weld root and produces a relatively deep and narrow weld. This change is the main cause of penetration increase. Moreover, arc construction can cause the weld width to become narrower and the penetration to become deeper, but this is not the main cause of penetration increase. The effects of flux on fluid flow of the weld pool surface and arc profiles were observed in conventional TIG welding and in A-TIG welding by using high-speed video camera. The fluid flow behavior was visualized in realtime scale by micro focused X-ray transmission video observation system. The result indicated that stronger inward fluid flow patterns leading to weld beads with narrower width and deeper penetration could be apparently identified in the case of A-TIG welding. The flux could change the direction of fluid flow in welding pool. It has a good agreement with the simulation results.

Similar content being viewed by others

References

Gurebich S M, Zamkov V N, Kushnirenko N A. Improving the penetration of titanium alloys when they are welded by argon tungsten arc process. Automat Weld, 1965, 18(9): 1–5

Tanaka M, Shimizu T, Terasaki T, et al. Effects of activating flux on arc phenomena in gas tungsten arc welding. Science and Technology of Welding and Joining, 2000, 5(6): 397–402

Simonik A G. The effect of contraction of the arc discharge upon the introduction of electro-negative elements. Welding Production, 1976, (3): 49–51

Heiple C R, Roper J R. Mechanism for minor element effect on GTA fusion zone geometry. Welding Journal, 1982, 61(4): 97–102

David S A, Debroy T, Vitek J M. Phenomenological modeling of fusion welding processes. MRS Bulletin, 1994, 19(1): 29–35

Kou S, Wang Y H. Weld pool convection and its effect. Welding Journal, 1986, 65(3): 63–70

Zacharia T, David S A, Vitek J M. Effect of evaporation and temperature-dependent material properties on weld pool development. Metallurgical and Materials Transactions B, 1991, 22(2): 233–241

Zhang Y M, Cao Z N, Kovacevic R. Numerical analysis of fully penetrated weld pools in gas tungsten arc welding. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 1996, 210(C2): 187–195

Voller V R, Cross M, Markatos N C. An enthalpy method for convection/diffusion phase change. International Journal for Numerical Methods in Engineering, 1987, 24(1): 271–284

Voller V R, Prakash C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. International Journal of Heat and Mass Transfer, 1987, 30(8): 1709–1719

Sahoo P, Debroy T, McNallan M J. Surface tension of binary metal-surface active solute systems under conditions relevant to welding metallurgy. Metallurgical and Materials Transactions B, 1988, 19(3): 483–491

Wang Y, Shi Q, Tsai H L. Modeling of the effects of surface-active elements on flow patterns and weld penetration. Metallurgical and Materials Transactions B, 2001, 32(1): 145–161

Hughes M, Taylor G A, Pericleous K. Thermo capillary and magnetohydrodynamic effects in modelling the thermodynamics of stationary welding processes. The PHOENICS Journal of Computational Fluid Dynamics and its Applications, 2000, 13(1): 99–113

Kim I S, Jung Y J, Son J S. Finite element modeling of GMA welding process. The PHOENICS Journal of Computational Fluid Dynamics and its Applications, 2000, 13(1): 56–69

Ohring S, Lugt H J. Numerical simulation of a time-dependent 3-D GMA weld pool due to a moving arc. Welding Journal, 1999, 78(12): 416–424

Cao Z N, Zhang Y M, Kovacevic R. Numerical dynamic analysis of moving GTA weld pool. Journal of Manufacturing Science and Engineering, 1998, 120(1): 173–178

Fan D, Zhang R, Gu Y, et al. Effect of flux on A-TIG welding of mild steels. Transactions of JWRI, 2001, 30(1): 35–40

Fujii H, Sato T, Lu S, et al. Development of an advanced A-TIG (AA-TIG) welding method by control of Marangoni convection. Materials Science and Engineering A, 2008, 495(1–2): 296–303

Heiple C R, Roper J R. Effect of selenium on GTAW fusion zone geometry. Welding Journal, 1981, 60(8): 143–145

Heiple C R, Roper J R, Stagner R T, et al. Surface active element effects on the shape of GTA, laser and electron beam welds. Welding Journal, 1982, 62(3): 72–77

Lucas W, Howse D S. Activating flux-increasing the performance and productivity of the TIG and plasma processes. Welding and Metal Fabrication, 1996, 64(l): 11–17

Howse D S, Lucas W. Investigation into arc constriction by active fluxes for tungsten inert gas welding. Science and Technology of Welding and Joining, 2000, 5(3): 189–193

Pierce S W, Burgardt P, Olson D L. Thermocapillary and arc phenomena in stainless steel welding. Welding Journal, 1999, 78(2): 45–52

Katayama S, Kawahito Y, Mizutani M. Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Physics Procedia, 2010, 5(2): 9–17

Naito Y, Mizutani M, Katayama S. Observation of keyhole behavior and melt flows during laser-arc hybrid welding. Proceedings of ICALEO, 2003, 1–9

Dong C, et al. The effect of individual compounds on weld penetration in plasma arc welding of stainless steel. Technical Report of BAMTRI, 2003, 1–12

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, RH., Pan, JL. & Katayama, S. The mechanism of penetration increase in A-TIG welding. Front. Mater. Sci. 5, 109–118 (2011). https://doi.org/10.1007/s11706-011-0125-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-011-0125-5