Abstract

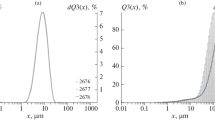

Iron powders with two different particle size distributions were compacted by high velocity compaction. The influences of particle size distribution and impact velocity on green properties, including green density, springback, tensile strength and bending strength etc., were studied with scanning electron microscopy (SEM) and a computer controlled universal testing machine. The results show that the particle size distribution and the impact velocity strongly affect its properties. Wider size distribution results in green compact with higher density and better strength. Furthermore, springback of compacts is lower produced by the powder with wider size distribution, especially for radial springback. As impact velocity increases, its green density and green strength gradually increases, but the increasing rate of density decreases gradually. No special relation is found between springback and impact velocity. In addition, the axial springback and the bending strength are higher than the radial springback and the tensile strength, respectively.

Similar content being viewed by others

References

Souriou D, Goeuriot P, Bonnefoy O, et al. Comparison of conventional and high velocity compaction of alumina powders. Advances in Science and Technology, 2006, 45: 893–898

Orban R L. New research directions in powder metallurgy. Romanian Reports in Physics, 2004, 56: 505–516

Skoglund P. High density PM parts by high velocity compaction. Powder Metallurgy, 2001, 44: 199–201

Skoglund P, Kejzelman M, Hauer I. High density PM components by high velocity compaction. In: Volker A, Chu C L, William F, et al. Proceedings of the 2002 World Congress on Powder Metallurgy and Particulate Materials. USA: Metal Powder Industries Federation, 2002, 85–95

Doremus P, Duwa F, Francois P, et al. High velocity compaction. In: Volker A, Chu C L, William F, et al. Proceedings of the 2002 World Congress on Powder Metallurgy and Particulate Materials. USA: Metal Powder Industries Federation, 2002, 96–110

Skagerstrand A. High velocity compaction of metal powders, a study on density and properties. In: Volker A, Chu C L, William F, et al. Proceedings of the 2002 World Congress on Powder Metallurgy and Particulate Materials. USA: Metal Powder Industries Federation, 2002, 111–116

Häggblad H Å, Hockauf M, Eriksson M, et al. Simulation of high velocity compaction of powder in a rubber mould with characterization of silicone rubber and titanium powder using a modified split Hopkinson set-up. Powder Technology, 2005, 154: 33–42

Jonsén P, Häggblad H Å, Troive L, et al. Green body behavior of high velocity pressed metal powder. Materials Science Forum, 2007, 534–536: 289–292

Dore F, Lazzarotto L, Bourdin S. High velocity compaction: overview of materials, applications and potential. Materials Science Forum, 2007, 534–536: 293–296

Bao C X, Shen Z Q, Shu Z P. The application of P/M advanced techniques to sintered gears. Materials Science Forum, 2007, 534–536: 321–324

Hokamoto K, Tanaka S, Fujita M, et al. High temperature shock consolidation of hard ceramic powders. Physica B: Condensed Matter, 1997, 239: 1–5

Sano T, Obinata A, Negishi H, et al. Effects of temperature rise on dynamic powder compaction. Journal of Materials Processing Technology, 1997, 67: 19–23

Li Y Y, Nagi T L, Zhang D T, et al. Effect of die wall lubrication on warm compaction powder metallurgy. Journal of Materials Processing Technology, 2002, 129: 354–358

Capus J M. Die wall lubrication aids higher density. Metal Powder Report, 1998, 53(9): 28

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Jz., Qu, Xh., Yin, Hq. et al. Effect of particle size distribution on green properties during high velocity compaction. Front. Mater. Sci. China 2, 392–396 (2008). https://doi.org/10.1007/s11706-008-0070-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-008-0070-0