Abstract

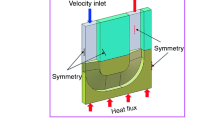

Droplet impacting on the stainless steel wire mesh is very common in chemical devices, like a rotating packed bed. Surface wettability of wire mesh significantly affects the liquid flow pattern and liquid dispersion performance. However, the effect of surface wettability on the impaction phenomena at microscale such as liquid film is still unknown. In this work, the dynamic behavior of liquid film on the surface of wire mesh was analyzed by computational fluid dynamics simulation. The dynamic behavior of liquid film on the surface of wire mesh can be divided into the following three steps: (1) spreading step; (2) shrinkage process; (3) stabilizing or disappearing step. Effects of surface wettability, as well as operating conditions, on wetting area and liquid film thickness were studied. Compared to the hydrophilic wire mesh, the final wetting area of hydrophobic wire mesh is zero in most cases. The average liquid film thickness on the surface of hydrophilic wire mesh is 30.02–77.29 µm, and that of hydrophobic wire mesh is 41.76–237.37 µm. This work provided a basic understanding of liquid film flow at microscale on the surface with various surface wettabilities, which can be guiding the packing optimization and design.

Similar content being viewed by others

References

Sun B C, Dong K, Zhao W, Wang J W, Chu G W, Zhang L L, Zou H K, Chen J F. Simultaneous absorption of NOx and SO2 into Na2SO3 solution in a rotating packed bed with preoxidation by ozone. Industrial & Engineering Chemistry Research, 2019, 58(19): 8332–8341

Luo Y, Luo J Z, Chu G W, Zhao Z Q, Arowo M, Chen J F. Investigation of effective interfacial area in a rotating packed bed with structured stainless steel wire mesh packing. Chemical Engineering Science, 2017, 170: 347–354

Wang P H, Zhuang L W, Dai G. Synergistic effect of droplet self-adjustment and rod bank internal on fluid distribution in a WFGD spray column. Chemical Engineering Science, 2017, 162: 227–244

Chen Q Y, Chu G W, Luo Y, Sang L, Zhang L L, Zou H K, Chen J F. Polytetrafluoroethylene wire mesh packing in a rotating packed bed: mass transfer studies. Industrial & Engineering Chemistry Research, 2016, 55(44): 11606–11613

Fourati M, Roig V, Raynal L. Experimental study of liquid spreading in structured packings. Chemical Engineering Science, 2012, 80: 1–15

Guo F, Chong Z, Guo K, Feng Y D, Gardner N C. Hydrodynamics and mass transfer in cross-flow rotating packed bed. Chemical Engineering Science, 1997, 52(21–22): 3853–3859

Schubert M, Hamidipour M, Duchesne C, Larachi F. Hydrodynamics of cocurrent two-phase flows in slanted porous media-modulation of pulse flow via bed obliquity. AIChE Journal, 2010, 56(12): 3189–3205

Spiegel L, Meier W. Distillation columns with structured packings in the next decade. Chemical Engineering Research & Design, 2003, 81(1): 39–47

Xu Y C, Li Y B, Liu Y Z, Luo Y, Chu G W, Zhang L L, Chen J F. Liquid jet impaction on the single-layer stainless steel wire mesh in a rotating packed bed reactor. AIChE Journal, 2019, 65(6): e16597

Chu G W, Gao X, Luo Y, Zou H K, Shao L, Chen J F. Distillation studies in a two-stage counter-current rotating packed bed. Separation and Purification Technology, 2013, 102: 62–66

Luo Y, Chu G W, Zou H K, Zhao Z Q, Dudukovic M P, Chen J F. Gas—liquid effective interfacial area in a rotating packed bed. Industrial & Engineering Chemistry Research, 2012, 51(50): 16320–16325

Nygaard H G, Kiil S, Johnsson J E, Jensen J N, Hansen J, Fogh F, Dam-Johansen K. Full-scale measurements of SO2 gas phase concentrations and slurry compositions in a wet flue gas desulphurisation spray absorber. Fuel, 2004, 83(9): 1151–1164

Gololo K V, Majozi T. Complex cooling water systems optimization with pressure drop consideration. Industrial & Engineering Chemistry Research, 2013, 52(22): 7056–7065

Ma J, Irfan H M, Wang Y F, Feng X, Xu D M. Recovering wastewater in a cooling water system with thermal membrane distillation. Industrial & Engineering Chemistry Research, 2018, 57(31): 10491–10499

Liu Z H, Li Y B, Su M J, Luo Y, Chu G W. Dispersion phenomena of liquid droplet impacting on the single fiber with different wettabilities. Chemical Engineering Science, 2022, 248: 117169

Ryu S, Sen P, Nam Y, Lee C. Water penetration through a superhydrophobic mesh during a drop impact. Physical Review Letters, 2017, 118(1): 014501

Su M J, Luo Y, Chu G W, Cai Y, Le Y, Zhang L L, Chen J F. Intensification of droplet dispersion by using multilayer wire mesh and its application in a rotating packed bed. Industrial & Engineering Chemistry Research, 2020, 59(8): 3584–3592

Manzello S L, Yang J C. An experimental study of a water droplet impinging on a liquid surface. Experiments in Fluids, 2002, 32(5): 580–589

Xie H, Koshizuka S, Oka Y. Modelling of a single drop impact onto liquid film using particle method. International Journal for Numerical Methods in Fluids, 2004, 45(9): 1009–1023

Lu X, Du X, Zeng M, Zhang S, Wang Q. Shell-side thermal-hydraulic performances of multilayer spiral-wound heat exchangers under different wall thermal boundary conditions. Applied Thermal Engineering, 2014, 70(2): 1216–1227

Tahir F, Mabrouk A, Koc M. Review on CFD analysis of horizontal falling film evaporators in multi effect desalination plants. Desalination and Water Treatment, 2019, 166: 296–320

Wang Q F, Li M X, Xu W J, Yao L, Liu X T, Su D D, Wang P. Review on liquid film flow and heat transfer characteristics outside horizontal tube falling film evaporator: CFD numerical simulation. International Journal of Heat and Mass Transfer, 2020, 163: 120440

Sun F D, Xu S L, Gao Y C. Numerical simulation of liquid falling film on horizontal circular tubes. Frontiers of Chemical Science and Engineering, 2012, 6(3): 322–328

Xue J X, Li Q S, Qi J, Wu Q P, Zhao H K, Zhang L Q. Multiscale study of wet pressure drop model for a novel structured wire gauze packing. Chemical Engineering Science, 2021, 230: 116179

Liao H L, Ouyang Y, Zhang J P, Zou H K, Chu G W, Luo Y. Numerical studies of liquid droplet impacting on single-layer hydrophilic and hydrophobic wire meshes. Industrial & Engineering Chemistry Research, 2022, 61(20): 7154–7162

Xie P, Lu X S, Yang X, Ingham D, Ma L, Pourkashanian M. Characteristics of liquid flow in a rotating packed bed for CO2 capture: a CFD analysis. Chemical Engineering Science, 2017, 172(23): 216–229

Liu Y, Luo Y, Chu G W, Luo J Z, Arowo M, Chen J F. 3D numerical simulation of a rotating packed bed with structured stainless steel wire mesh packing. Chemical Engineering Science, 2017, 170: 365–377

Jeon S S, Kim S J, Park G C. Numerical study of condensing bubble in subcooled boiling flow using volume of fluid model. Chemical Engineering Science, 2011, 66(23): 5899–5909

Yang Y C, Xiang Y, Chu G W, Zou H K, Sun B C, Arowo M, Chen J F. CFD modeling of gas—liquid mass transfer process in a rotating packed bed. Chemical Engineering Journal, 2016, 294: 111–121

Su M J, Luo Y, Chu G W, Cai Y, Le Y, Zhang L L, Chen J F. Dispersion behaviors of droplet impacting on wire mesh and process intensification by surface micro/nano-structure. Chemical Engineering Science, 2020, 219: 115593

Shih T H, Liou W W, Shabbir A, Yang Z G, Zhu J. A new k—ε eddy viscosity model for high Reynolds number turbulent flows. Computers & Fluids, 1995, 24(3): 227–238

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 22022802).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liao, HL., Jiang, L., Yu, HX. et al. Numerical studies of dynamic behavior of liquid film on single-layer wire mesh with different wettabilities. Front. Chem. Sci. Eng. 16, 1672–1680 (2022). https://doi.org/10.1007/s11705-022-2205-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-022-2205-8