Abstract

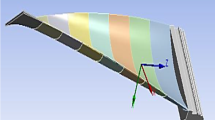

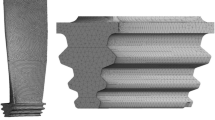

Severe localized serious cracks of 0Cr17Ni4Cu4Nb alloy turbine blades after years of service are analyzed by means of the macro-morphology, micro-morphology (SEM) and energy dispersion spectrum (EDS). The centrifugal stress and vibration characteristics of the blades are calculated and analyzed under the prestressed condition by finite element simulation. The results show that the failure of the blades is due to the stress corrosion mainly. The impeller blade system cannot avoid the region of “triple points” resonance during the actual operation, and torsional deformation occurs under this vibration stress. Stress concentration leads to the crack initiation and propagation, and fatigue cracks appear and then propagate. Corrosive elements of O, Na and S found on the surface of fracture will accelerate the corrosion.

Similar content being viewed by others

References

P. Balachandra Shetty, R.K. Mishra, S.S. Prithvi et al., Finite element approach for failure analysis of a gas turbine. J. Fail. Anal. Prev. 18, 1210–1215 (2018)

S. Cano, J.A. Rodríguez, J.M. Rodríguez et al., Detection of damage in steam turbine blades caused by low cycle and strain cycling fatigue. Eng. Fail. Anal. 97, 579–588 (2019)

W.Q. Huang, X.G. Yang, S.L. Li, Evaluation of service-induced microstructural damage for directionally solidified turbine blade of aircraft engine. Rare Met. 38, 157–164 (2019)

E. Poursaeidi, A.M. Niaei, M. Lashgari et al., Experimental studies of erosion and corrosion interaction in an axial compressor first stage rotating blade material. Appl. Phys. A-Mater 124, 10–14 (2018)

A. Kermanpur, H.S. Amin, S. Ziaei-Rad et al., Failure analysis of Ti6Al4V gas turbine compressor blades. Eng. Fail. Anal. 15, 1052–1064 (2008)

Q. Li, Z.Y. Liu, L. Lu et al., Failure analysis of ZG06Cr13Ni4Mo stainless steel hydraulic turbine blades. Corros. Sci. Prot. Technol. 26, 249–253 (2014)

S. Asadikouhanjani, M. Torfeh, R. Ghorbanf, Failure analysis of a heavy duty gas turbine blade. Strength Mater 46, 608–612 (2014)

V. Hendrik, E. Dennis, S. Jayendran et al., Accelerated cathodic reaction in microbial corrosion of iron due to direct electron uptake by sulfate-reducing bacteria. Corros. Sci. 66, 88 (2013)

Z.P. Wang, D.L. Fu, Y. Zhong, Study on the effect of impeller on vibration characteristics of blades of turbines. Noise Vib. Control 34, 94–96 (2014)

E. Poursaeidi, A.M. Niaei, M. Arablu et al., Experimental investigation on erosion performance and wear factors of custom 450 steel as the first row blade material of an axial compressor. Int. J. Surf. Sci. Eng. 11, 85–99 (2017)

J.A. Segura, L. Castro, I. Rosales et al., Diagnostic and failure analysis in blades of a 300 MW steam turbine. Eng. Fail. Anal. 82, 631–641 (2017)

S. Kovacs, T. Beck, L. Singheiser, Influence of mean stresses on fatigue life and damage of a turbine blade steel in the VHCF-regime. Int. J. Fatigue 49, 90–99 (2012)

A.A. Hamed, W. Tabakoff, R.B. Rivir et al., Turbine blade surface deterioration by erosion. J. Turbomach. 127, 445–452 (2005)

J. Kanesund, H. Brodin, S. Johansson, Hot corrosion influence on deformation and damage mechanisms in turbine blades made of IN-792 during service. Eng. Fail. Anal. 96, 118–129 (2019)

S. Rani, A.K. Agrawal, V. Rastogi, Vibration analysis for detecting failure mode and crack location in first stage gas turbine blade. J. Mech. Sci. Technol. 33, 1–10 (2019)

W.S. Zhao, H. Li, M.X. Xue et al., Vibration analysis for failure detection in low pressure steam turbine blades in nuclear power plant. Eng. Fail. Anal. 84, 11–24 (2018)

S. Madhavan, R. Jain, C. Sujatha et al., Vibration based damage detection of rotor blades in a gas turbine engine. Eng. Fail. Anal. 46, 26–39 (2014)

G.C. Tsai, Rotating vibration behavior of the turbine blades with different groups of blades. J. Sound Vib. 271, 547–575 (2004)

E. Poursaeidi, A. Babaei, Arhani, M.R. Mohammadi et al., Effects of natural frequencies on the failure of R1 compressor blades. Eng. Fail. Anal. 25, 304–315 (2012)

S. Kumar, N. Roy, R. Ganguli, Monitoring low cycle fatigue damage in turbine blade using vibration characteristics. Mech. Syst. Signal Process. 21, 480–501 (2007)

D.S. Li, S.C.M. Ho, G.B. Song et al., A review of damage detection methods for wind turbine blades. Smart Mater. Struct. 24, 104–115 (2015)

Acknowledgments

This work was financially supported by the Education Department Foundation in Shaanxi, China (No. 18JK0348), Xi’an Polytechnic University Foundation in Shaanxi, China (No. 107020023).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, J., Zhang, L., Wang, Y. et al. Experimental and Simulated Analysis of Failure Mechanism of 0Cr17Ni4Cu4Nb Stainless Steel Blade. J Fail. Anal. and Preven. 19, 1509–1515 (2019). https://doi.org/10.1007/s11668-019-00758-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00758-z