Abstract

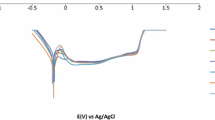

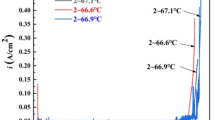

The corrosion behavior of 2101 duplex and 301 austenitic stainless steel in the presence of sulfate (SO4 2−) anion concentrations was investigated through polarization techniques, weight loss and optical microscopy analysis. The corrosion rates of the steels were comparable after 3M H2SO4. Results confirm that the duplex steel displayed a higher resistance to pitting corrosion than the austenitic steel. Experimental observation shows that its pitting potential depends on the concentration of the SO4 2− ions in the acid solution due to adsorption of anions at the metal-film interface. The duplex steel underwent stable pitting at relatively higher potentials and significantly higher corrosion current than the austenitic steel. The duplex steel exhibited lower corrosion potential values thus less likely to polarize in the acid solution. Solution concentration had a limited influence on the polarization behavior of the austenitic steel and hence its reaction to SO4 2− ion penetration from analysis of the pitting potentials and observation of its narrower polarization scans compared to the duplex steel which showed wide scatter over the potential domain with changes in concentration.

Similar content being viewed by others

References

D.E. Williams, M.R. Kilburn, J. Cliff, G.I.N. Waterhouse, Composition changes around sulphide inclusions in stainless steels, and implications for the initiation of pitting corrosion. Corros. Sci. 52, 3702–3716 (2010)

D.A. Jones, Principles and Prevention of Corrosion (Macmillan Publishing Company, New York, 1992), p. 208

R.W. Revie, H.H. Uhlig, Corrosion and Corrosion Control (Wiley, New Jersey, 2008)

P.C. Pistorius, G.T. Burstein, Metastable pitting corrosion of stainless steel and the transition to stability. Philos. Trans.: Phys. Sci. Eng. 341, 531–559 (1992)

P.C. Pistorius, G.T. Burstein, Growth of corrosion pits on stainless steel in chloride solution containing dilute sulphate. Corros. Sci. 33, 1885–1897 (1992)

P. Ernst, N.J. Laycock, M.H. Moayed, R.C. Newman, The mechanism of lacy cover formation in pitting. Corros. Sci. 39, 1133–1136 (1997)

N.J. Laycock, R.C. Newman, Temperature dependence of pitting potentials for austenitic stainless steels above their critical pitting temperature. Corros. Sci. 40, 887–902 (1998)

J. Soltis, Passivity breakdown, pit initiation and propagation of pits in metallic materials—review. Corros. Sci. 90, 5–22 (2015)

ASTM G1 - 03(2011) Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens. http://www.astm.org/Standards/G1. Retrieved 30 May 2016

ASTM G59 - 97(2014) Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements. http://www.astm.org/Standards/G31 Retrieved 30 May 2016

ASTM G102 - 89(2015)e1 Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements. http://www.astm.org/Standards/G31. Retrieved 30 May 2016

Y. Choi, S. Nesic, S. Ling, Effect of H2S on the CO2 corrosion of carbon steel in acidic solutions. Electrochim. Acta 56, 1752–1760 (2011)

ASTM NACE/ASTMG31 - 12a (2012) Standard Guide for Laboratory Immersion Corrosion Testing of Metals. http://www.astm.org/Standards/G31. Retrieved 05 May 2016

P. Venkatesan, B. Anand, P. Matheswaran, Influence of formazan derivatives on corrosion inhibition of mild steel in hydrochloric acid medium. Eur. J. Chem. 6(S1), S438–S444 (2009)

W.B. Jensen, The Lewis Acid-Base Concepts (Wiley, New York, 1980), pp. 112–336

K. Fushimi, M. Seo, Initiation of a local breakdown of passive film on iron due to chloride ions generated by a liquid-phase ion-gun for local breakdown. J. Electrochem. Soc. 148(11), B456–B459 (2001)

K. Fushimi, K. Azumi, M. Seo, Use of a liquid-phase ion-gun for local breakdown of the passive film on iron. J. Electrochem. Soc. 147(2), 552–557 (2000)

K.E. Heusler, L. Fisher, Kinetics of pit initiation at passive iron. Mater. Corros. 27(8), 551–556 (1976)

G.L. Song, Transpassivation of Fe-Cr-Ni stainless steels. Corros. Sci. 47, 1953–1987 (2005)

J. Kruger, Uhlig’s Corrosion Handbook R. Winstone Revie (Ed.) (Wiley, New Jersey, 2011)

M. Bojinov, G. Fabricius, T. Laitinen, T. Saario, Transpassivity mechanism of iron-chromium-molybdenum alloys studied by AC impedance, DC resistance and RRDE measurements. Electrochim. Acta 44, 4331–4343 (1999)

A. Sara, Y. Yongsun, C. Pyungyeon, J. Changheui, B. Philip, Passivity breakdown of 316L stainless steel during potentiodynamic polarization in NaCl solution. Corros. Sci. 111, 720–727 (2016)

G.S. Frankel, Pitting corrosion of metals: a review of the critical factors. J. Electrochem. Soc. 145, 2186–2198 (1998)

H. Bohni, Breakdown of passivity and localized corrosion process. Langmuir 3(6), 924–930 (1987)

R.T. Loto, Pitting corrosion evaluation of austenitic stainless steel type 304 in acid chloride media. J. Mater. Environ. Sci. 4(4), 448–459 (2013)

H.H. Uhlig, Adsorbed and reaction-product films on metals. J. Electrochem. Soc. 97, 215C–220C (1950)

R.T. Loto, Pitting corrosion evaluation and inhibition of stainless steels: a review. J. Mater. Environ. Sci. 6(10), 2750–2762 (2015)

T.P. Hoar, D.C. Mears, G.P. Rothwell, The relationships between anodic passivity, brightening and pitting. Corros. Sci. 5, 279–289 (1965)

G.S. Frankel, Pitting corrosion of metals: a review of the critical factors. J. Electrochem. Soc. 145(6), 2186–2198 (1998)

N. Sato, A theory for breakdown of anodic oxide films on metals. Electrochim. Acta 16, 1683–1692 (1971)

N. Sato, K. Kudo, T. Noda, The anodic oxide film on iron in neutral solution. Electrochim. Acta 16, 1909–1921 (1971)

W. Fredriksson, S. Malmgren, T. Gustafsson, M. Gorgoi, K. Edström, Full depth profile of passive films on 316L stainless steel based on high resolution HAXPES in combination with ARXPS. Appl. Surf. Sci. 258(15), 5790–5797 (2012)

K. Ahmad, Principles of Corrosion Engineering and Corrosion Control (Butterworth-Heinemann, Oxford, 2006)

J. Dong, J. Zhou, An investigation of pitting initiation mechanism of 1Cr12Ni2W1Mo1 V steel after induction hardening. J. Mater. Sci. 35, 2653–2657 (2000)

H.H. Strehblow, P. Marcus, J. Oudar (eds.), Corrosion Mechanisms in Theory and Practice (Marcel Dekker, New York, 1995)

A. Bentour, S. Diamond, N.S. Berke, Steel Corrosion in Concrete (Chapman & Hall, London, 1997)

A.R. Brooks, C.R. Clayton, K. Doss, Y.C. Lu, On the role of Cr in the passivity of stainless steel. J. Electr. Sci. 133, 2459–2464 (1986)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Loto, R.T., Loto, C.A. Potentiodynamic Polarization Behavior and Pitting Corrosion Analysis of 2101 Duplex and 301 Austenitic Stainless Steel in Sulfuric Acid Concentrations. J Fail. Anal. and Preven. 17, 672–679 (2017). https://doi.org/10.1007/s11668-017-0291-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0291-6