Abstract

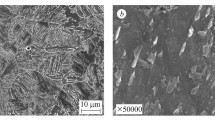

A structural steel component that failed under fatigue was examined with the aim to identify the root causes of this failure. Fractographic examination revealed the presence of multiple beach marks; the position and arrangement of those signified the occurrence of fatigue fracture under the presence of combined loading conditions, involving torsion and bending stress components. Crack initiation was observed also at the corners of the steel plate where non-metallic inclusions were located. Stereo-microscopical examination of the fracture surface likely revealed the presence of casting inclusions, probably fluxes or slag particles, near the surface and in the interior of the component. These inclusions could be considered inherent—metallurgical stress raisers, behaving as locations of prominent crack nucleation under cyclic fatigue loading, stimulating subsequent crack propagation and final ultimate rupture.

Similar content being viewed by others

References

S. Papaefthymiou, A. Vazdirvanidis, G. Pantazopoulos, C. Goulas, Root cause analysis of an early fatigue failure of a boron flat steel component designed for heavy duty structural applications, in Proceedings of 4th International Conference of Engineering Against Failure (ICEAF IV), 24–26 June 2015, Skiathos, pp. 834–841

A.S.M. Handbook, Failure Analysis and Prevention, vol. 11 (ASM International, Materials Park, 1992)

G. Totten, Fatigue crack propagation. Adv. Mater. Processes 166(5), 39–41 (2008)

G. Pantazopoulos, S. Zormalia, A. Vazdirvanidis, Investigation of fatigue failure of roll shafts in a tube manufacturing line. J. Fail. Anal. Prev. 10, 358–362 (2010)

G. Pantazopoulos, S. Zormalia, Analysis of the failure mechanism of a gripping tool steel failure operated in an industrial tube draw bench. Eng. Fail. Anal. 18, 1595–1604 (2011)

G. Pantazopoulos, Bending fatigue failure of a helical pinion bevel gear. J. Fail. Anal. Prev. 15, 219–226 (2015)

M. Fonte, M. de Freitas, Marine main engine crankshaft failure analysis: a case study. Eng. Fail. Anal. 16, 1940–1947 (2009)

G. Pantazopoulos, S. Papaefthymiou, Failure and fracture analysis of austenitic stainless steel marine propeller shaft. J. Fail. Anal. Prev. 15, 762–767 (2015)

D.J. Wulpi, Understanding How Components Fail, 2nd edn. (ASM International, Materials Park, 2005)

N.W. Sachs, Practical Plant Failure Analysis (CRC Press, Boca Raton, 2007)

N.W. Sachs, Understanding the surface features of fatigue fractures: how they describe the failure cause and the failure history. J. Fail. Anal. Prev. 5(2), 11–15 (2005)

J. Maciejewski, The effects of sulphide inclusions on mechanical properties and failures of steel components. J. Fail. Anal. Prev. 15, 169–178 (2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Papaefthymiou, S., Vazdirvanidis, A., Pantazopoulos, G. et al. Fatigue Fracture of a High-Resistance Structural Steel Component Destined to Sustain Severe Loads Under Service Conditions. J Fail. Anal. and Preven. 17, 79–85 (2017). https://doi.org/10.1007/s11668-016-0216-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-016-0216-9