Abstract

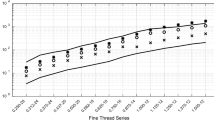

This paper presents results from tests on the reuse of locknuts with a prevailing torque locking feature. Aerospace and non-aerospace products are tested. Many qualification specifications provide reuse requirements for prevailing torque locking features in terms of unseated reuses. This paper provides data for comparison of locknut reuse for unseated and seated to preload conditions. All locknuts tested, except one, maintain required prevailing torque levels over 15 unseated reuses as typically required. The unseated reuse tests exhibit a moderate decrease in prevailing torque with reuse with the largest decrease usually occurring during the first reuse. The effect of seating to preload is a higher loss in prevailing torque compared with the unseated results. Reuse in seated conditions does not generally meet unseated requirements. Between 10 and 25% of the assembly prevailing torque is lost during initial seating to preload. This loss continues with reuse but at a lower rate. However, inconsistent fluctuations in prevailing torque are observed for tests with high preload of 85% yield strength of the bolt. For all the seated to preload reuse tests, the tightening torque to achieve a set preload increased with reuse, despite the corresponding reduction in prevailing torque. This phenomenon results from the breakdown of the solid film or as-received lubricant provided with the locknuts.

Similar content being viewed by others

References

NASM25027: Nut, self-locking, 250°F, 450°F and 800°F. National Aerospace Standard (1999)

NASM8846: Inserts, screw-thread, helical coil. National Aerospace Standard (1998)

MIL-I-45914A: Insert, screw thread—locked in, key locked. Department of Defense Military Specification (1991)

MIL-I-45932/1C: Insert, screw thread—thin wall, locked in. Department of Defense Military Specification (1994)

NAS3350: Nuts, self-locking, 450°F and 800°F, high quality. National Aerospace Standard (2006)

MIL-DTL-18240F: Fastener element, self-locking, threaded fastener—250°F maximum. Department of Defense Detail Specification (1997)

NASA-STD-5020: Requirements for threaded fastening systems in spaceflight hardware. NASA Technical Standard (2011)

IFI 100/107: Prevailing-torque type steel hex and hex flange nuts. Industrial Fasteners Institute (1987)

Light, D.J., Strange, R.N.: Vibration and static testing to determine the reusability of fastener locking systems. British Aerospace Dynamics Group, Report No. ST.19226 (1978)

NAS 1003 thru 1020. National Aerospace Standard (1991)

NAS 1149. National Aerospace Standard (1994)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zimandy, A.J.C., Hess, D.P. Effect of Reuse of Locknuts with Prevailing Torque Locking Feature. J Fail. Anal. and Preven. 13, 121–127 (2013). https://doi.org/10.1007/s11668-013-9653-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-013-9653-x