Abstract

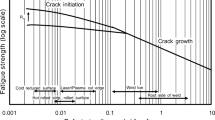

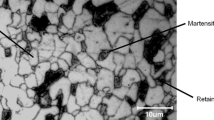

Mechanical cut-edge properties influence the fatigue lives and formability capacity of advanced high-strength steels. This factor is critical as S355MC and DP600 exhibited an increased sensitivity to fatigue cracks initiating from defects on the cut-edge fracture zone. Mechanical cut-edges as a result displayed a decreased level of formability that was highly dependent on the cut-edge surface and internal microstructure of the cut-edge produced. It was determined that, by controlling the mechanical clearance, optimized mechanical cut-edges were produced. This was achieved through minimizing surface damage and by controlling the internal and topographical properties of the cut-edge zones.

Similar content being viewed by others

Abbreviations

- A :

-

Elongation to failure

- AHSS:

-

Advanced high-strength steel

- HEC:

-

Hole expansion capacity

- HSLA:

-

High-strength low alloy

- H V :

-

Vickers hardness

- MPa:

-

Mega Pascal

- R :

-

Stress ratio (min stress/max stress)

- R a :

-

Arithmetic mean of departures from the mean line

- R p :

-

Maximum height of profile above the mean line

- R v :

-

Maximum depth of profile below the mean line

- S-N:

-

Stress-life

- Wt:

-

Weight

References

Meurling, F., Melander, A., Linder, J., Larsson, M.: The influence of mechanical and laser cutting on the fatigue strengths of carbon and stainless sheet steels. Scand. J. Metall. 30, 309–319 (2001)

Vass, A., Heijne, J.: Fatigue performance of cut edges. Corus Technical Report, Reference Source Number 134315 (2007)

Van-Goethem, R.P.M., Ament, P.C.H.: Influences of some parameters on the sheet cutting process of cold and hot rolled steel. Corus Technical Report, Reference Source Number 10325 (2000)

Matsumoto, Y., Hashimoto, F., Lahoti, G.: Surface integrity generated by precision hard turning. Ann. CIRP. 48(1), 50–53 (1999)

Marronne, E., Labesse-Jied, F., Galtier, A., Robert, J.L.: Influence of a cut edge on steel sheets fatigue properties. In: Fatigue 2003, Angers (2003)

Parsons, A.S.: The formula for successful punching. http://www.thefabricator.com/Punching/Punching_Article.cfm?ID=1415. Accessed 4 April 2007 (2006)

Melander, A., Meurling, F., Linder, J.: Comparison of the fatigue characteristics of punched and laser cut stainless steel sheets. In: Fatigue design 1998, Espoo, pp. 351–372 (1998)

Zelinski, P.: http://www.mmsonline.com/articles/010602.html. Accessed 20 April 2010 (2007)

Zorev, N.N.: Metal Cutting Mechanics. Pergamon, Oxford (1966)

Johnson, W., Mamalis, A.G.: The perforation of circular plates with four-sided pyramidally headed square-section punches. Int. J. Mech. Sci. 20, 849–866 (1978)

Wang, N.M., Wenner, M.L.: An analytical and experimental study of stretch flanging. Int. J. Mech. Sci. 16, 135–143 (1974)

Kumagai, T., Saiki, H.: Deformation analysis of hole flanging with ironing of thick sheet metals. Met. Mater. 4(4), 711–714 (1999)

Cho, Y.R., Chung, J.H., Ku, H.H., Kim, I.B.: Effect of controlled cooling on the formability of TS 590 MPa grade hot-rolled high strength steels. Met. Mater. 5(6), 571–578 (1999)

Chitkara, N.R., Johnson, W.: Hole flanging and piercing of circular plate. Sheet Met. Ind. 51(10), 635–640 (1974)

Strijbos, G.H., Boesenkool, R.: Hole expansion in hot rolled steels. In: Proceedings of the 19th IDDRG Biennial Congress, Eger, 10–14 June 1996, pp. 459–466 (1996)

Asnafi, N.: On stretch and shrink flanging of sheet aluminium by fluid forming. J. Mater. Process. Technol. 96, 198–214 (1999)

Cho, Y.R., Chung, J.H., Ku, H.H., Kim, I.B.: A study on the stretch flangeability of hot-rolled high strength steel with ferrite–bainite duplex microstructures. Korean J. Mater. Res. 9(12), 1252–1262 (1999)

Keeler, S: Cutting sheet metal reduces edge formability. The Science of Forming Magazine Article. March 1999. (1999)

Auto Steel Partnership Auto Steel Partnership: http://www.asp.org/database/custom/hss_stampingDesignManual.pdf. Accessed 16 May 2010 (2000)

Acknowledgments

The present research was funded by a grant from the Engineering and Physical Sciences Research Council (EPSRC). The author wishes to thank the support of Swansea University College of Engineering and the Engineering Centre for Manufacturing and Materials during the pursuit of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thomas, D.J. Effect of Mechanical Cut-Edges on the Fatigue and Formability Performance of Advanced High-Strength Steels. J Fail. Anal. and Preven. 12, 518–531 (2012). https://doi.org/10.1007/s11668-012-9591-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-012-9591-z