Abstract

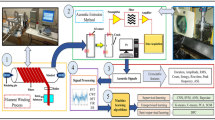

Vibration monitoring of rolling element bearings is possibly the most established diagnostic technique for rotating machinery. The application of Acoustic Emission (AE) for bearing diagnosis is gaining ground as a complementary diagnostic tool, however, limitations in the successful application of the AE technique have been partly due to the difficulty in processing, interpreting and classifying the acquired data. Furthermore, the extent of bearing damage has eluded the AE diagnostician. The investigation reported in this paper was centered on the application of the Acoustic Emission technique for identifying the size of a defect on a radially loaded bearing. An experimental test-rig was designed such that defects of varying sizes could be seeded onto the outer race of a test bearing. It was concluded that AE can provide an indication of the defect size, thus allowing the user to monitor the rate of degradation on the bearing.

Similar content being viewed by others

References

Mathews, J.R.: Acoustic Emission. Gordon and Breach Science Publishers Inc., New York (1983), ISSN 0730-7152

Roger, L.M.: The application of vibration analysis and acoustic emission source location to on-line condition monitoring of anti-friction bearings. Tribol. Int. 12(2), 51–59 (1979)

Mba, D., Bannister, R.H., Findlay, G.E.: Condition monitoring of low-speed rotating machinery using stress waves: Part’s I and II. Proc. Inst. Mech. Eng. 213(E), 153–185 (1999)

Jamaludin, N., Mba, D., Bannister, R.H.: Condition monitoring of slow-speed rolling element bearings using stress waves. Journal of Process Mechanical Engineering, I Mech E. Pro. Inst. Mech Eng. 215(E4), 245–271 (2001)

Yoshioka, T., Fujiwara, T.: New acoustic emission source locating system for the study of rolling contact fatigue. Wear 81(1), 183–186 (1982)

Yoshioka, T., Fujiwara, T.: Application of acoustic emission technique to detection of rolling bearing failure. Am. Soc. Mech. Eng. 14, 55–76 (1984), Production Engineering Division publication PED

Hawman, M.W., Galinaitis, W.S.: Acoustic Emission monitoring of rolling element bearings. In: Proceedings of the IEEE, Ultrasonics symposium, pp. 885–889 (1988)

Holroyd, T.J., Randall, N.: Use of acoustic emission for machine condition monitoring. Brit. J. Non-Destr. Test. 35(2), 75–78 (1993)

Holroyd, T.: Condition monitoring of very slowly rotating machinery using AE techniques. In: 14th International Congress on Condition Monitoring and Diagnostic Engineering Management (COMADEM’2001), Manchester, UK, 4–6 September 2001, 29, ISBN 0080440363

Bagnoli, S., Capitani, R., Citti, P.: Comparison of accelerometer and acoustic emission signals as diagnostic tools in assessing bearing. In: Proceedings of 2nd International Conference on Condition Monitoring, pp. 117–125. London, UK (May 1988)

Morhain, A., Mba, D.: Bearing defect diagnosis and acoustic emission. J. Eng. Tribol. I Mech E 217(4), Part J, 257–272 (2003), ISSN 1350-6501

Author information

Authors and Affiliations

Corresponding author

Additional information

This article was originally published as “The Use of Acoustic Emission for Estimation of Bearing Defect Size” in Essential Technologies for Successful Prognostics, Proceedings of the 59th Meeting of the Society for Machinery Failure Prevention Technology, Society for Machinery Failure Prevention Technology, 2005, pp. 583–591, and is reprinted with permission.

Rights and permissions

About this article

Cite this article

Mba, D. The Use of Acoustic Emission for Estimation of Bearing Defect Size. J Fail. Anal. and Preven. 8, 188–192 (2008). https://doi.org/10.1007/s11668-008-9119-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-008-9119-8