Abstract

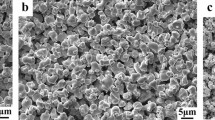

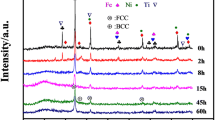

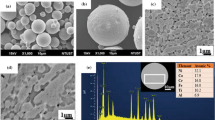

High-temperature oxidation in coal-fired power stations is a major challenge. Thermal spraying is a prospective surface modification method to deposit protective coatings to combat the severe effects of oxidation at high temperature. Plasma spraying (PS) is a completely developed industrial technique proficient in producing dense coatings on complex-shaped components. In this current investigation, Inconel625-30%Al2O3 composite coatings were deposited by varying the size of hard ceramic Al2O3 particles (micro-, nano-, and bimodal) in the ductile Inconel625 matrix. The developed composites were evaluated in respect of their microstructural analysis of as-sprayed and oxidized coatings, phase analysis, porosity, and microhardness using various standard techniques. The oxidation tests were executed at a temperature of 900 °C under cyclic conditions to determine the high-temperature oxidation resistance of developed Inconel625-30%Al2O3 (micro-, nano-, and bimodal) composite coatings. The coatings after oxidation studies obey the parabolic rate of oxidation and were capable of minimizing the degradation of respective substrate steel against oxidation. In comparison with micro- and nano-forms, the bimodal composition showed superior oxidation resistance. The oxide phases Al2O3, Cr2O3, TiO2, and spinel such as NiCr2O4 developed during the oxidation process were responsible for the better oxidation resistance of bimodal coatings. The better out-turn of PS bimodal coating was connected with better microstructures and better interactions among micro- and nano-Al2O3 reinforcement.

Similar content being viewed by others

References

K. Szymański et al., Thermally Sprayed Coatings Resistant to Erosion and Corrosion for Power Plant Boilers-A Review, Surf. Coat. Technol., 2015, 268, p 153-164.

G. Prashar, H. Vasudev, and L. Thakur, High-Temperature Oxidation and Erosion Resistance of Ni-Based Thermally-Sprayed Coatings Used in Power Generation Machinery: A Review, Surf. Rev. Lett., 2022, 29(3), p 2230003-2230005.

H. Vasudev et al., High Temperature Oxidation and Erosion Behaviour of HVOF Sprayed Bi-Layer Alloy-718/NiCrAlY Coating, Surf. Coat. Technol., 2019, 362, p 366-380.

G. Prashar and H. Vasudev, Surface Topology Analysis of Plasma Sprayed Inconel625-Al2O3 Composite Coating, Mater. Today Proc., 2022, 50, p 607-611.

A. Anupam et al., Understanding the Microstructural Evolution of High Entropy Alloy Coatings Manufactured by Atmospheric Plasma Spray Processing, Appl. Surf. Sci., 2020, 505, p 144117.

M.J. Tobar et al., Morphology and Characterization of Laser Clad Composite NiCrBSi-WC Coatings on Stainless Steel, Surf. Coat. Technol., 2006, 200(22–23), p 6313-6317.

H. Wang, W. Xia, and Y. Jin, A Study on Abrasive Resistance of Ni-Based Coatings with a WC Hard Phase, Wear, 1996, 195(1–2), p 47-52.

C.A.I. Bin et al., Tribological Properties of TiC Particles Reinforced Ni-Based Alloy Composite Coatings, Trans. Nonferrous Met. Soc. China, 2013, 23(6), p 1681-1688.

H. Vasudev et al., An Investigation on Oxidation Behaviour of High Velocity Oxy-Fuel Sprayed Inconel718-Al2O3 Composite Coatings, Surf. Coat. Technol., 2020, 393, p 125770.

S. Buytoz et al., Microstructural and Wear Characteristics of High Velocity Oxygen Fuel (HVOF) Sprayed NiCrBSi-SiC Composite Coating on SAE 1030 Steel, Arabian J. Sci. Eng., 2013, 38(6), p 1481-1491.

S. Harsha, D.K. Dwivedi, and A. Agarwal, Influence of CrC Addition in Ni-Cr-Si-B Flame Sprayed Coatings on Microstructure, Microhardness and Wear Behavior, Int. J. Adv. Manuf. Technol., 2008, 38(1–2), p 93-101.

A.S. Praveen and A. Arjunan, Effect of Nano-Al2O3 Addition on the Microstructure and Erosion Wear of HVOF Sprayed NiCrSiB Coatings, Mater. Res. Express, 2019, 7(1), p 015006.

H. Vasudev et al., A study on Processing and Hot Corrosion Behaviour of HVOF Sprayed Inconel718-Nano Al2O3 Coatings, Mater. Today Commun., 2020, 25, p 101626.

S. Dosta, Alumina Reinforcement of Inconel 625 Coatings by Cold Gas Spraying, Metals, 2020, 10(9), p 1263.

H.S. Grewal, H. Singh, and A. Agrawal, Microstructural and Mechanical Characterization of Thermal Sprayed nickel–alumina Composite Coatings, Surf. Coat. Technol., 2013, 216, p 78-92.

A.S. Praveen et al., Erosion Wear Behaviour of Plasma Sprayed NiCrSiB/Al2O3 Composite Coating, Int. J. Refract. Met. Hard Mater., 2015, 52, p 209-218.

H. Koivuluoto and P. Vuoristo, Effect of Ceramic Particles on Properties of Cold-Sprayed Ni-20Cr+Al2O3 Coatings, J. Therm. Spray Technol., 2009, 18(4), p 555.

H.X. Hu et al., Cavitation Erosion and Jet Impingement Erosion Mechanism of Cold Sprayed Ni-Al2O3 Coating, Nucl. Eng. Des., 2011, 241(12), p 4929-4937.

W.Y. Li et al., Characterizations of Cold-Sprayed Nickel–Alumina Composite Coating with Relatively Large Nickel-Coated Alumina Powder, Surf. Coat. Technol., 2008, 202(19), p 4855-4860.

M. Bai et al., Preparation of MCrAlY-Al2O3 Composite Coatings with Enhanced Oxidation Resistance Through a Novel Powder Manufacturing Process, J. Therm. Spray Technol., 2019, 28(3), p 433-443.

B. Wang and S.W. Lee, Erosion–Corrosion Behaviour of HVOF NiAl-Al2O3 Intermetallic-Ceramic Coating, Wear, 2000, 239(1), p 83-90.

H.J. Kim et al., Assessment of Wear Performance of Flame Sprayed and Fused Ni-Based Coatings, Surf. Coat. Technol., 2003, 172(2–3), p 262-269.

R. Verma and G. Kaushal, Comparative High Temperature Oxidation Studies of HVOF IN 625 Coating on T22 Boiler Steel at 900 °C and 700 °C, Mater. Today Proc., 2021, 41, p 812-820.

R. Kumar, V.K. Tewari, and S. Prakash, Cyclic Oxidation Behaviour of 1Cr-0.5Mo (T11) Boiler Tube Steel and its Weldments in Air at 900 °C, Oxid. Met., 2016, 86(1–2), p 89-98.

S.E. Sadique et al., High Temperature Oxidation Behavior of Iron-Chromium-Aluminium Alloys, Oxid. Met., 2000, 54(5), p 385-400.

C. Burman, T. Ericsson, in Proceedings of the Symposium High Temperature Protective Coatings, March 7–8, Atlanta, GA, USA, ed. by S.C. Singhal, (Metallurgical Society of AIME, Warrendale, PA, USA, 1983) p 51-59

J.G. Odhiambo et al., Porosity and its Significance in Plasma-Sprayed Coatings, Coatings, 2019, 9(7), p 460.

E. Sadeghimeresht, N. Markocsan, and P. Nylén, A Comparative Study on Ni-Based Coatings Prepared by HVAF, HVOF, and APS Methods for Corrosion Protection Applications, J. Therm. Spray Technol., 2016, 25(8), p 1604-1616.

E.P. Song et al., Microstructure and Wear Resistance of Nanostructured Al2O3–8wt.% TiO2 Coatings Plasma-Sprayed with Nanopowders, Surf. Coat. Technol., 2006, 201(3–4), p 1309-1315.

D. Goberman et al., Microstructure Development of Al2O3–13wt.% TiO2 Plasma Sprayed Coatings Derived from Nanocrystalline Powders, Acta Mater., 2002, 50(5), p 1141-1152.

C.S. Ramesh et al., Slurry Erosive Wear Behaviour of Thermally Sprayed Inconel 718 Coatings by APS Process, Wear, 2011, 271, p 1365-1371.

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, JWS, UK, 2008.

J. Zhu et al., Boron Nitride Nanoplatelets Induced Synergetic Strengthening and Toughening Effects on Splats and their Boundaries of Plasma Sprayed Hydroxyapatite Coatings, Ceram. Int., 2018, 44(9), p 10604-10610.

F. Long et al., Synergistic Strengthening Effect of Carbon Nanotubes (CNTs) and Titanium Diboride (TiB2) Microparticles on Mechanical Properties of Copper Matrix Composites, J. Mater. Res. Technol., 2020, 9(4), p 7989-8000.

S. Queyreau, G. Monnet, and B. Devincre, Orowan Strengthening and Forest Hardening Superposition Examined by Dislocation Dynamics Simulations, Acta Mater., 2010, 58(17), p 5586-5595.

D.S. Zhou et al., Suppressing Al2O3 Nanoparticle Coarsening and Cu Nanograin Growth of Milled Nanostructured Cu–5vol.% Al2O3 Composite Powder Particles by Doping with Ti, J. Mater. Sci. Technol., 2017, 33(11), p 1323-1328.

K. Deng et al., Microstructure and Strengthening Mechanism of Bimodal Size Particle Reinforced Magnesium Matrix Composite, Compos. A Appl. Sci. Manuf., 2012, 43(8), p 1280-1284.

K.K. Deng et al., Effects of Bimodal Size SiC Particles on the Microstructure Evolution and Fracture Mechanism of AZ91 Matrix at Room Temperature, Mater. Sci. Eng. A, 2012, 553, p 74-79.

G. Skandan et al., Multimodal Powders: A New Class of Feedstock Material for Thermal Spraying of Hard Coatings, Scr. Mater., 2001, 44(8–9), p 1699-1702.

M. Kumar, H. Singh, and N. Singh, Production of Nanocrystalline Ni-20Cr Coatings for High-Temperature Applications, J. Therm. Spray Technol., 2014, 23(4), p 692-707.

M. Kumar, H. Singh, and N. Singh, High Temperature Oxidation Behavior of a Novel Ni-20Cr Alloy Powder Coating on T22 Steel, in Proceedings of the International Thermal Spray Conference (ITSC-2013), (Busan, Republic of Korea, 2013), p 120-125

N.N. Khoi, W.W. Smeltzer, and J.D. Embury, 1975 Growth and Structure of Nickel Oxide on Nickel Crystal Faces, J. Electrochem. Soc., 1975, 122(11), p 1495.

F. Azarmi et al., Microstructure Characterization of Alloy 625 Deposited on Nickel Foam Using Air Plasma Spraying, Adv. Eng. Mater., 2008, 10(5), p 459-465.

S. Prakash et al., Tube Failures in Coal Fired Boilers, in Proceedings National Seminar on Advances in Material and Processing, 9–10th Nov (IIT, Roorkee, India 2001), p 245

S. Srikanth et al., Analysis of Failures in Boiler Tubes Due to Fireside Corrosion in a Waste Heat Recovery Boiler, Eng. Fail. Anal., 2003, 10(1), p 59-66.

M. Krzyzanowski, J.H. Beynon, and D.C. Farrugia, Oxide Scale Behavior in High Temperature Metal Processing (JWS, 2010)

B. Singh, Ph.D. Thesis, Indian Institute of Technology Roorkee, Roorkee, India, 2003

H. Singh, Characterization of Oxide Scales to Evaluate High Temperature Oxidation Behavior of Ni-20Cr Coated Superalloys, Mater. Sci. Eng. A, 2007, 464(1–2), p 110-116.

G. Calvarin, R. Molins, and A.M. Huntz, Oxidation Mechanism of Ni-20Cr Foils and its Relation to the Oxide-Scale Microstructure, Oxid. Met., 2000, 53(1–2), p 25-48.

Y. Longa-Nava et al., Hot Corrosion of Nickel-Chromium and Nickel-Chromium-Aluminum Thermal-Spray Coatings by Sodium Sulfate-Sodium Metavanadate Salt, Corrosion, 1996, 52(09), p 680-689.

K.M. Doleker et al., Effect of High Temperature Oxidation on Inconel 718 and Inconel 718/YSZ/Gd2Zr2O7, Mater. Res. Express., 2019, 6(8), p 086456.

S.Y. Qu et al., Effects of Cr and Al on high temperature oxidation resistance of Nb-Si system intermetallics, in Materials Science Forum, vol 546 (Trans Tech Publications Ltd., 2007), p 1485-1488

F.H. Stott and G.C. Wood, Internal Oxidation, Mater. Sci. Technol., 1988, 4(12), p 1072-1078.

S.R.J. Saunders and J.R. Nicholls, Coatings and Surface Treatments for High Temperature Oxidation Resistance, Mater. Sci. Technol., 1989, 5(8), p 780-798.

U.K. Chatterjee, S.K. Bose, and S.K. Roy, Environmental degradation of metals: corrosion technology series/14. (CRC Press, 2001)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Prashar, G., Vasudev, H. Structure–Property Correlation of Plasma-Sprayed Inconel625-Al2O3 Bimodal Composite Coatings for High-Temperature Oxidation Protection. J Therm Spray Tech 31, 2385–2408 (2022). https://doi.org/10.1007/s11666-022-01466-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01466-1