Abstract

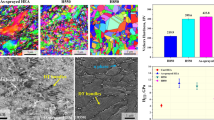

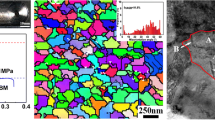

High-entropy alloys (HEAs) represent a new alloy design paradigm that involves simultaneous mixing of multiple elements in an equimolar or near-equimolar composition to form multi-principal solid solutions with unusual mechanical properties. In this work, CoCrFeNiMn HEA deposits with a near-full density were successfully prepared by a solid-state cold spray additive manufacturing process. In particular, cold spray process conditions such as carrier gas temperature and pressure, particle velocity, and particle size were studied to identify the effective cold spray process window. The as-deposited CoCrFeNiMn HEA deposits are featured by highly heterogeneous and significantly refined grain structures that lead to enhanced micro-hardness compared with conventional cast counterparts. The effects of heat treatment conditions on the microstructure and mechanical properties of the cold-sprayed CoCrFeNiMn HEA deposits are also discussed in order to understand their thermal stability.

Similar content being viewed by others

References

E.P. George, D. Raabe and R.O. Ritchie, High-Entropy Alloys, Nat. Rev. Mater, 2019, 4(8), p 515-534.

M.-H. Tsai and J.-W. Yeh, High-Entropy Alloys: A Critical Review, Mater. Res. Lett., 2014, 2(3), p 107-123.

L. Fan, T. Yang, Y. Zhao, J. Luan, G. Zhou, H. Wang, Z. Jiao and C.-T. Liu, Ultrahigh Strength and Ductility in Newly Developed Materials with Coherent Nanolamellar Architectures, Nat. Commun., 2020, 11(1), p 6240.

K. Yao, L. Liu, J. Ren, Y. Guo, Y. Liu, Y. Cao, R. Feng, F. Wu, J. Qi, J. Luo, P.K. Liaw and W. Chen, High-Entropy Intermetallic Compound with Ultra-High Strength and Thermal Stability, Scr. Mater., 2021, 194, p 113674.

S.S. Nene, M. Frank, K. Liu, S. Sinha, R.S. Mishra, B.A. McWilliams and K.C. Cho, Corrosion-Resistant High Entropy Alloy with High Strength and Ductility, Scr. Mater., 2019, 166, p 168-172.

J. Ren, C. Mahajan, L. Liu, D. Follette, W. Chen and S. Mukherjee, Corrosion Behavior of Selectively Laser Melted CoCrFeMnNi High Entropy Alloy, Metals, 2019, 9(10), p 1029.

N.A.P.K. Kumar, C. Li, K.J. Leonard, H. Bei and S.J. Zinkle, Microstructural Stability and Mechanical Behavior of FeNiMnCr High Entropy Alloy under Ion Irradiation, Acta Mater., 2016, 113, p 230-244.

A.V. Kuznetsov, D.G. Shaysultanov, N.D. Stepanov, G.A. Salishchev and O.N. Senkov, Tensile Properties of an AlCrCuNiFeCo High-Entropy Alloy in as-Cast and Wrought Conditions, Mater. Sci. Eng. A, 2012, 533, p 107-118.

H. Wu, S. Liu, Y. Zhang, H. Liao, R.-N. Raoelison and S. Deng, New Process Implementation to Enhance Cold Spray-Based Additive Manufacturing, J. Therm. Spray Technol., 2021, 30(5), p 1284-1293.

T. Stoltenhoff, H. Kreye and H.J. Richter, An Analysis of the Cold Spray Process and Its Coatings, J. Therm. Spray Technol., 2002, 11(4), p 542-550.

H.-J. Kim, C.-H. Lee and S.-Y. Hwang, Superhard Nano WC–12%Co Coating by Cold Spray Deposition, Mater. Sci. Eng. A, 2005, 391(1–2), p 243-248.

S. Yin, Y. Xie, J. Cizek, E.J. Ekoi, T. Hussain, D.P. Dowling and R. Lupoi, Advanced Diamond-Reinforced Metal Matrix Composites via Cold Spray: Properties and Deposition Mechanism, Compos. B Eng, 2017, 113, p 44-54.

K. Yang, W. Li, X. Guo, X. Yang and Y. Xu, Characterizations and Anisotropy of Cold-Spraying Additive-Manufactured Copper Bulk, J. Mater. Sci. Technol., 2018, 34(9), p 1570-1579.

M.R. Rokni, C.A. Widener, G.A. Crawford and M.K. West, An Investigation into Microstructure and Mechanical Properties of Cold Sprayed 7075 Al Deposition, Mater. Sci. Eng. A, 2015, 625, p 19-27.

W. Wong, E. Irissou, A.N. Ryabinin, J.-G. Legoux and S. Yue, Influence of Helium and Nitrogen Gases on the Properties of Cold Gas Dynamic Sprayed Pure Titanium Coatings, J. Therm. Spray Technol., 2011, 20(1–2), p 213-226.

M. Tului, C. Bartuli, A. Bezzon, A.L. Marino, F. Marra, S. Matera and G. Pulci, Amorphous Steel Coatings Deposited by Cold-Gas Spraying, Metals, 2019, 9(6), p 678.

W. Sun, A. Bhowmik, A.W.-Y. Tan, R. Li, F. Xue, I. Marinescu and E. Liu, Improving Microstructural and Mechanical Characteristics of Cold-Sprayed Inconel 718 Deposits via Local Induction Heat Treatment, J. Alloys Compd., 2019, 797, p 1268-1279.

W. Ma, Y. Xie, C. Chen, H. Fukanuma, J. Wang, Z. Ren and R. Huang, Microstructural and Mechanical Properties of High-Performance Inconel 718 Alloy by Cold Spraying, J. Alloys Compd., 2019, 792, p 456-467.

B. AL-Mangour, R. Mongrain, E. Irissou and S. Yue, Improving the Strength and Corrosion Resistance of 316L Stainless Steel for Biomedical Applications Using Cold Spray, J. Therm. Spray. Technol., 2013, 216, p 297-307.

S. Yoon, G. Bae, Y. Xiong, S. Kumar, K. Kang, J.-J. Kim and C. Lee, Strain-Enhanced Nanocrystallization of a CuNiTiZr Bulk Metallic Glass Coating by a Kinetic Spraying Process, Acta Mater., 2009, 57(20), p 6191-6199.

J. Henao, A. Concustell, S. Dosta, G. Bolelli, I.G. Cano, L. Lusvarghi and J.M. Guilemany, Deposition Mechanisms of Metallic Glass Particles by Cold Gas Spraying, Acta Mater., 2017, 125, p 327-339.

S. Yin, W. Li, B. Song, X. Yan, M. Kuang, Y. Xu, K. Wen and R. Lupoi, Deposition of FeCoNiCrMn High Entropy Alloy (HEA) Coating via Cold Spraying, J. Mater. Sci. Technol., 2019, 35(6), p 1003-1007.

Y. Xu, W. Li, L. Qu, X. Yang, B. Song, R. Lupoi and S. Yin, Solid-State Cold Spraying of FeCoCrNiMn High-Entropy Alloy: An Insight into Microstructure Evolution and Oxidation Behavior at 700–900 °C, J. Mater. Sci. Technol., 2021, 68, p 172-183.

A. Anupam, S. Kumar, N.M. Chavan, B.S. Murty and R.S. Kottada, First Report on Cold-Sprayed AlCoCrFeNi High-Entropy Alloy and Its Isothermal Oxidation, J. Mater. Res., 2019, 34(5), p 796-806.

A.I. Yurkova, D.V. Hushchyk and A.V. Minitsky, Synthesis of High-Entropy AlNiCoFeCrTi Coating by Cold Spraying, Powder Metall. Met. Ceram., 2021, 59(11–12), p 681-694.

J.-E. Ahn, Y.-K. Kim, S.-H. Yoon and K.-A. Lee, Tuning the Microstructure and Mechanical Properties of Cold Sprayed Equiatomic CoCrFeMnNi High-Entropy Alloy Coating Layer, Met. Mater. Int., 2021, 27(7), p 2406-2415.

J. Lehtonen, H. Koivuluoto, Y. Ge, A. Juselius and S.-P. Hannula, Cold Gas Spraying of a High-Entropy CrFeNiMn Equiatomic Alloy, Coatings, 2020, 10(1), p 53.

J. Wu, H. Fang, S. Yoon, H. Kim and C. Lee, Measurement of Particle Velocity and Characterization of Deposition in Aluminum Alloy Kinetic Spraying Process, Appl. Surf. Sci., 2005, 252(5), p 1368-1377.

S. Yin, X. Wang, W. Li, H. Liao and H. Jie, Deformation Behavior of the Oxide Film on the Surface of Cold Sprayed Powder Particle, Appl. Surf. Sci., 2012, 259, p 294-300.

T. Schmidt, F. Gärtner, H. Assadi and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729-742.

P.C. King and M. Jahedi, Relationship between Particle Size and Deformation in the Cold Spray Process, Appl. Surf. Sci., 2010, 256(6), p 1735-1738.

S. Pathak and G. Saha, Development of Sustainable Cold Spray Coatings and 3D Additive Manufacturing Components for Repair/Manufacturing Applications: A Critical Review, Coatings, 2017, 7(8), p 122.

C.-J. Li, H.-T. Wang, Q. Zhang, G.-J. Yang, W.-Y. Li and H.L. Liao, Influence of Spray Materials and Their Surface Oxidation on the Critical Velocity in Cold Spraying, J. Therm. Spray Technol., 2010, 19(1–2), p 95-101.

M. Meyer and R. Lupoi, An Analysis of the Particulate Flow in Cold Spray Nozzles, Mech. Sci., 2015, 6(2), p 127-136.

F. Otto, Y. Yang, H. Bei and E.P. George, Relative Effects of Enthalpy and Entropy on the Phase Stability of Equiatomic High-Entropy Alloys, Acta Mater., 2013, 61(7), p 2628-2638.

P.P. Bhattacharjee, G.D. Sathiaraj, M. Zaid, J.R. Gatti, C. Lee, C.-W. Tsai and J.-W. Yeh, Microstructure and Texture Evolution during Annealing of Equiatomic CoCrFeMnNi High-Entropy Alloy, J. Alloys Compd., 2014, 587, p 544-552.

F. Otto, A. Dlouhý, Ch. Somsen, H. Bei, G. Eggeler and E.P. George, The Influences of Temperature and Microstructure on the Tensile Properties of a CoCrFeMnNi High-Entropy Alloy, Acta Mater., 2013, 61(15), p 5743-5755.

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George and R.O. Ritchie, A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications, Science, 2014, 345(6201), p 1153-1158.

S. Peng, S. Mooraj, R. Feng, L. Liu, J. Ren, Y. Liu, F. Kong, Z. Xiao, C. Zhu, P.K. Liaw and W. Chen, Additive Manufacturing of Three-Dimensional (3D)-Architected CoCrFeNiMn High- Entropy Alloy with Great Energy Absorption, Scr. Mater., 2021, 190, p 46-51.

S. Guan, D. Wan, K. Solberg, F. Berto, T. Welo, T.M. Yue and K.C. Chan, Additive Manufacturing of Fine-Grained and Dislocation-Populated CrMnFeCoNi High Entropy Alloy by Laser Engineered Net Shaping, Mater. Sci. Eng. A, 2019, 761, p 138056.

B. Cantor, I.T.H. Chang, P. Knight and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213-218.

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5–6), p 794.

S. Yin, M. Meyer, W. Li, H. Liao and R. Lupoi, Gas Flow, Particle Acceleration, and Heat Transfer in Cold Spray: A Review, J. Therm. Spray Technol., 2016, 25(5), p 874-896.

T. Schmidt, F. Gaertner and H. Kreye, New Developments in Cold Spray Based on Higher Gas and Particle Temperatures, J. Therm. Spray Technol., 2006, 15(4), p 488-494.

S.V. Klinkov, V.F. Kosarev and M. Rein, Cold Spray Deposition: Significance of Particle Impact Phenomena, Aerosp. Sci. Technol., 2005, 9(7), p 582-591.

C.-J. Li, W.-Y. Li and H. Liao, Examination of the Critical Velocity for Deposition of Particles in Cold Spraying, J. Therm. Spray Technol., 2006, 15(2), p 212-222.

K. Yokoyama, M. Watanabe, S. Kuroda, Y. Gotoh, T. Schmidt and F. Gaumlrtner, Simulation of Solid Particle Impact Behavior for Spray Processes, Mater. Trans., 2006, 47(7), p 1697-1702.

X.-T. Luo, M.-L. Yao, N. Ma, M. Takahashi and C.-J. Li, Deposition Behavior, Microstructure and Mechanical Properties of an in-Situ Micro-Forging Assisted Cold Spray Enabled Additively Manufactured Inconel 718 Alloy, Mater. Des., 2018, 155, p 384-395.

X. Qiu, N.U.H. Tariq, L. Qi, J.-Q. Wang and T.-Y. Xiong, A Hybrid Approach to Improve Microstructure and Mechanical Properties of Cold Spray Additively Manufactured A380 Aluminum Composites, Mater. Sci. Eng. A, 2020, 772, p 138828.

M.A. Meyers, Y.B. Xu, Q. Xue, M.T. Pérez-Prado and T.R. McNelley, Microstructural Evolution in Adiabatic Shear Localization in Stainless Steel, Acta Mater., 2003, 51(5), p 1307-1325.

Y. Zou, W. Qin, E. Irissou, J.-G. Legoux, S. Yue and J.A. Szpunar, Dynamic Recrystallization in the Particle/Particle Interfacial Region of Cold-Sprayed Nickel Coating: Electron Backscatter Diffraction Characterization, Scr. Mater., 2009, 61(9), p 899-902.

M.N. Gussev and K.J. Leonard, In Situ SEM-EBSD Analysis of Plastic Deformation Mechanisms in Neutron-Irradiated Austenitic Steel, J. Nucl. Mater., 2019, 517, p 45-56.

Q. Wang, N. Ma, M. Takahashi, X. Luo and C. Li, Development of a Material Model for Predicting Extreme Deformation and Grain Refinement during Cold Spraying, Acta Mater., 2020, 199, p 326-339.

C. Lee and J. Kim, Microstructure of Kinetic Spray Coatings: A Review, J. Therm. Spray Technol., 2015, 24(4), p 592-610.

V.S. Bhattiprolu, K.W. Johnson and G.A. Crawford, Influence of Powder Microstructure on the Microstructural Evolution of As-Sprayed and Heat Treated Cold-Sprayed Ti-6Al-4V Coatings, J. Therm. Spray Technol., 2019, 28(1–2), p 174-188.

T. Liu, J.D. Leazer and L.N. Brewer, Particle Deformation and Microstructure Evolution during Cold Spray of Individual Al-Cu Alloy Powder Particles, Acta Mater., 2019, 168, p 13-23.

Y. Zhang, N. Brodusch, S. Descartes, J.M. Shockley, R. Gauvin and R.R. Chromik, The Effect of Submicron Second-Phase Particles on the Rate of Grain Refinement in a Copper-Oxygen Alloy During Cold Spray, J. Therm. Spray Technol., 2017, 26(7), p 1509-1516.

D. Goldbaum, J. Ajaja, R.R. Chromik, W. Wong, S. Yue, E. Irissou and J.-G. Legoux, Mechanical Behavior of Ti Cold Spray Coatings Determined by a Multi-Scale Indentation Method, Mater. Sci. Eng. A, 2011, 530, p 253-265.

V. Luzin, K. Spencer and M.-X. Zhang, Residual Stress and Thermo-Mechanical Properties of Cold Spray Metal Coatings, Acta Mater., 2011, 59(3), p 1259-1270.

M. Saleh, V. Luzin and K. Spencer, Analysis of the Residual Stress and Bonding Mechanism in the Cold Spray Technique Using Experimental and Numerical Methods, J. Mater. Sci. Technol., 2014, 252, p 15-28.

W.-Y. Li, H. Liao, C.-J. Li, H.-S. Bang and C. Coddet, Numerical Simulation of Deformation Behavior of Al Particles Impacting on Al Substrate and Effect of Surface Oxide Films on Interfacial Bonding in Cold Spraying, Appl. Surf. Sci., 2007, 253(11), p 5084-5091.

S. Sampath, X.Y. Jiang, J. Matejicek, L. Prchlik, A. Kulkarni and A. Vaidya, Role of Thermal Spray Processing Method on the Microstructure, Residual Stress and Properties of Coatings: An Integrated Study for Ni–5 Wt.%Al Bond Coats, Mater. Sci. Eng. A, 2004, 364(1–2), p 216-231.

P. Hou, Y. Li, W. Zhang, D. Chae, J.-S. Park, Y. Ren, Y. Gao and H. Choo, Synchrotron x-Ray Diffraction and Crystal Plasticity Modeling Study of Martensitic Transformation Texture Development, and Stress Partitioning in Deep-Drawn TRIP Steels, Materialia, 2021, 18, p 101162.

P. Hou, Y. Li, D. Chae, Y. Ren, K. An and H. Choo, Lean Duplex TRIP Steel: Role of Ferrite in the Texture Development, Plastic Anisotropy, Martensitic Transformation Kinetics, and Stress Partitioning, Materialia, 2021, 15, p 100952.

K. Spencer, V. Luzin, N. Matthews and M.-X. Zhang, Residual Stresses in Cold Spray Al Coatings: The Effect of Alloying and of Process Parameters, Surf. Coat. Technol., 2012, 206(19–20), p 4249-4255.

W. Chen, T. Voisin, Y. Zhang, J.-B. Florien, C.M. Spadaccini, D.L. McDowell, T. Zhu and Y.M. Wang, Microscale Residual Stresses in Additively Manufactured Stainless Steel, Nat. Commun., 2019, 10(1), p 4338.

Acknowledgments

W.C. is grateful for the support from the US National Science Foundation (CMMI-1927621) and the U.S. Army Research Laboratory under Cooperative Agreement Award No. HQ0034-15-2-0007. The authors would like to thank Yuchen Li in the Department of Civil and Environmental Engineering, University of Massachusetts Amherst for his assistance during the nanoindentation experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of Technology Hyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

Rights and permissions

About this article

Cite this article

Feng, S., Guan, S., Story, W.A. et al. Cold Spray Additive Manufacturing of CoCrFeNiMn High-Entropy Alloy: Process Development, Microstructure, and Mechanical Properties. J Therm Spray Tech 31, 1222–1231 (2022). https://doi.org/10.1007/s11666-022-01374-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01374-4