Abstract

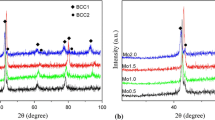

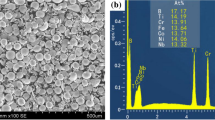

Amorphous alloys possess excellent mechanical properties such as high hardness and high wear resistance. CoCrFeNiBSi high-entropy alloys with amorphous phase have been prepared on the surface of H13 steel by utilizing various laser line energies. The microstructure, phase, hardness, and wear resistance of the cladding coatings were studied. The glass-forming ability of different cladding coatings was compared by observing the change on the dilution rate. The results show that the coatings consisted of an amorphous phase and a crystallization phase, which contained FeNi3, α-Co, and Cr2C. As the laser line energy was increased, the dilution rate of the coatings increased and the content of the amorphous phase decreased. Coatings with high content of amorphous phase showed satisfied hardness and wear resistance.

Similar content being viewed by others

References

J. Zhu, Z. Zhang, and J. Xie, Improving Strength and Ductility of H13 Die Steel by Pre-tempering Treatment and Its Mechanism, Mater. Sci. Eng. A, 2019, 752, p 101-114

M. Pérez and F.J. Belzunce, A Comparative Study of Salt-Bath Nitrocarburizing and Gas Nitriding Followed by Post-oxidation Used as Surface Treatments of H13 Hot Forging Dies, Surf. Coat. Technol., 2016, 305, p 146-157

J. Marashi, E. Yakushina, P. Xirouchakis, R. Zante, and J. Foster, An Evaluation of H13 Tool Steel Deformation in Hot Forging Conditions, J. Mater. Process. Technol., 2017, 246, p 276-284

X. Zhao, B. Wang, D. Sun, C. Li, L. Han, and J. Gu, Effect of Pre-existing VC Carbides on Nitriding and Wear Behavior of Hot-Work Die Steel, Appl. Surf. Sci., 2019, 486, p 179-186

J.Z. Lu, J. Cao, H.F. Lu, L.Y. Zhang, and K.Y. Luo, Wear Properties and Microstructural Analyses of Fe-Based Coatings with Various WC Contents on H13 Die Steel by Laser Cladding, Surf. Coat. Technol., 2019, 369, p 228-237

S.L. Wang, Z.Y. Zhang, Y.B. Gong, and G.M. Nie, Microstructures and Corrosion Resistance of Fe-Based Amorphous/Nanocrystalline Coating Fabricated by Laser Cladding, J. Alloys Compd., 2017, 728, p 1116-1123

Y. Lu, G. Huang, Y. Wang, H. Li, Z. Qin, and X. Lu, Crack-Free Fe-Based Amorphous Coating Synthesized by Laser Cladding, Mater. Lett., 2018, 210, p 46-50

H. Zong, C. Geng, C. Kang, G. Cao, L. Bian, L. Li, B. Zhang, and M. Li, Excellent Glass Forming Ability and Plasticity in High Entropy Zr20Ti20Hf20M20Be20 (M = Cu, Ni, Co) Alloys, Results Phys., 2018, 8, p 253-256

P. Jinhong, H. Xiancong, and W. Zhangzhong, Preparation of High Entropy Alloy Cu29Zr32Ti15Al5Ni19 with High Glass Forming Ability, Rare Metal. Mater. Eng., 2017, 46(7), p 1810-1814

J. Kim, H.S. Oh, J. Kim, C.W. Ryu, G.W. Lee, H.J. Chang, and E.S. Park, Utilization of High Entropy Alloy Characteristics in Er-Gd-Y-Al-Co High Entropy Bulk Metallic Glass, Acta Mater., 2018, 155, p 350-361

Y.Y. Zhao, Y.X. Ye, C.Z. Liu, R. Feng, K.F. Yao, and T.G. Nieh, Tribological Behavior of an Amorphous Zr20Ti20Cu20Ni20Be20 High-Entropy Alloy Studied Using a Nanoscratch Technique, Intermetallics, 2019, 113, p 106561

Z. Cai, Y. Wang, X. Cui, G. Jin, Y. Li, Z. Liu, and M. Dong, Design and Microstructure Characterization of FeCoNiAlCu High-Entropy Alloy Coating by Plasma Cladding: In Comparison with Thermodynamic Calculation, Surf. Coat. Technol., 2017, 330, p 163-169

L. Liu, J.B. Zhu, C. Hou, J.C. Li, and Q. Jiang, Dense and Smooth Amorphous Films of Multicomponent FeCoNiCuVZrAl High-Entropy Alloy Deposited by Direct Current Magnetron Sputtering, Mater. Des., 2013, 46, p 675-679

C. Wang, J. Yu, Y. Zhang, and Y. Yu, Phase Evolution and Solidification Cracking Sensibility in Laser Remelting Treatment of the Plasma-Sprayed CrMnFeCoNi High Entropy Alloy Coating, Mater. Des., 2019, 182, p 108040

Y. Guo and Q. Liu, MoFeCrTiWAlNb Refractory High-Entropy Alloy Coating Fabricated by Rectangular-Spot Laser Cladding, Intermetallics, 2018, 102, p 78-87

Y.F. Juan, J. Li, Y.Q. Jiang, W.L. Jia, and Z.J. Lu, Modified Criterions for Phase Prediction in the Multi-Component Laser-Clad Coatings and Investigations into Microstructural Evolution/Wear Resistance of FeCrCoNiAlMox Laser-Clad Coatings, Appl. Surf. Sci., 2019, 465, p 700-714

L. Jiang, W. Wu, Z. Cao, D. Deng, and T. Li, Microstructure Evolution and Wear Behavior of the Laser Cladded CoFeNi2V0.5Nb0.75 and CoFeNi2V0.5Nb High-Entropy Alloy Coatings, J. Therm. Spray Technol., 2016, 25(4), p 806-814

C.L. Wu, S. Zhang, C.H. Zhang, H. Zhang, and S.Y. Dong, Phase Evolution and Properties in Laser Surface Alloying of FeCoCrAlCuNix High-Entropy Alloy on Copper Substrate, Surf. Coat. Technol., 2017, 315, p 368-376

Y.Q. Jiang, J. Li, Y.F. Juan, Z.J. Lu, and W.L. Jia, Evolution in Microstructure and Corrosion Behavior of AlCoCrxFeNi High-Entropy Alloys Coatings Fabricated by Laser Cladding, J. Alloy Compd., 2019, 775, p 1-14

Y. Guo, X. Shang, and Q. Liu, Microstructure and Properties of In-Situ TiN Reinforced Laser Cladding CoCr2FeNiTix High-Entropy Alloy Composite Coatings, Surf. Coat. Technol., 2018, 344, p 353-358

F.Y. Shu, S. Liu, H.Y. Zhao, W.X. He, S.H. Sui, J. Zhang, P. He, and B.S. Xu, Structure and High-Temperature Property of Amorphous Composite Coating Synthesized by Laser Cladding FeCrCoNiSiB High-Entropy Alloy Powder, J. Alloys Compd., 2018, 731, p 662-666

P. Schoderböck, Investigation of Complex Residual Stress States in the Near-Surface Region: Evaluation of the Complete Stress Tensor by X-Ray Diffraction Pattern Decomposition, Appl. Surf. Sci., 2019, 466, p 151-164

X. Gao, X. Lin, J. Yu, Y. Li, Y. Hu, W. Fan, S. Shi, and W. Huang, Selective Laser Melting (SLM) of In-Situ Beta Phase Reinforced Ti/Zr-Based Bulk Metallic Glass Matrix Composite, Scr. Mater., 2019, 171, p 21-25

L. Yang, T. Ge, G.Q. Guo, C.L. Huang, X.F. Meng, S.H. Wei, D. Chen, and L.Y. Chen, Atomic and Cluster Level Dense Packing Contributes to the High Glass-Forming Ability in Metallic Glasses, Intermetallics, 2013, 34, p 106-111

B. Fultz, Vibrational Thermodynamics of Materials, Prog. Mater. Sci., 2010, 55(4), p 247-352

Z.J. Yan, J.F. Li, S.R. He, and Y.H. Zhou, Evaluation of the Optimum Solute Concentration for Good Glass Forming Ability in Multicomponent Metallic Glasses, Mater. Res. Bull., 2003, 38(4), p 681-689

F. Shu, B. Yang, S. Dong, H. Zhao, B. Xu, F. Xu, B. Liu, P. He, and J. Feng, Effects of Fe-to-Co Ratio on Microstructure and Mechanical Properties of Laser Cladded FeCoCrBNiSi High-Entropy Alloy Coatings, Appl. Surf. Sci., 2018, 450, p 538-544

F. Shu, B. Zhang, T. Liu, S. Sui, Y. Liu, P. He, B. Liu, and B. Xu, Effects of Laser Power on Microstructure and Properties of Laser Cladded CoCrBFeNiSi High-Entropy Alloy Amorphous Coatings, Surf. Coat. Technol., 2019, 358, p 667-675

Acknowledgments

This study was supported by National Natural Science Foundation of China (Grant No. 51905126), State Key Lab of Advanced Welding and Joining, Harbin Institute of Technology, the China Postdoctoral Science Foundation-General Program (Grant No. 2018M641822), and National Natural Science Foundation of China (General Program, Grant No. 51875129).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shu, F., Wang, B., Zhao, H. et al. Effects of Line Energy on Microstructure and Mechanical Properties of CoCrFeNiBSi High-Entropy Alloy Laser Cladding Coatings. J Therm Spray Tech 29, 789–797 (2020). https://doi.org/10.1007/s11666-020-01004-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01004-x