Abstract

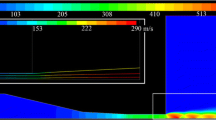

Cold spray is a green additive manufacturing method that accelerates micron-size particles to supersonic speeds. At these high speeds, the particles deposit upon impact with a desired surface. High-density polyethylene, polyurethane, polyamide-12, polystyrene, and ultra-high molecular weight polyethylene particles were cold-sprayed onto a low-density polyethylene substrate under different process conditions. Glass beads with diameters between 20 and 120 µm were added to each batch to study the effect of non-adhesive peening particles on the deposition efficiency and the quality of the final deposited layer of a series different polymeric powders. The successful deposition window was compared for the cold spray process with and without the addition of glass beads. Adding the glass beads to the polymer powders was found to widen the successful windows of deposition to both higher and lower impact velocities at a given temperature for all the polymer powder studied. In addition, adding peening particles were found to make deposition possible at lower particle temperatures where deposition had not been successful previously. This was especially important for ultra-high molecular weight polyethylene particles for which deposition in the absence of peening particles was not possible below 60 °C, but with peening particles was successful even at room temperature. Peening particles were found to increase deposition efficiency by as much as 50% for a given set of deposition conditions. The appropriate size of the added glass beads to maximize the deposition efficiency was found to be comparable to the size of the depositing particles. The addition of glass beads was also found to reduce the surface roughness of the deposited layer by more than 50%. Finally, for processing conditions with particle velocities below a Mach number of one, no glass beads were found to adhere to the resulting cold-sprayed substrates.

Similar content being viewed by others

References

F.S. da Silva, N. Cinca, S. Dosta, I.G. Cano, J.M. Guilemany, C.S.A. Caires, A.R. Lima, C.M. Silva, S.L. Oliveira, A.R.L. Caires, and A.V. Benedetti, Corrosion Resistance and Antibacterial Properties of Copper Coating Deposited by Cold Gas Spray, Surf. Coat. Technol., 2019, 361, p 292-301

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkhimov, and V.M. Fomin, Cold Spray Technology, Elsevier, Amsterdam, 2007

T.P. Bush, Z. Khalkhali, V.K. Champagne, D.P. Schmidt, and J.P. Rothstein, Optimization of Cold Spray Deposition of High-Density Polyethylene Powders, Therm. Spray Technol., 2017, 26(7), p 1548-1564

Z. Khalkhali, W. Xie, V.K. Champagneb, J.-H. Lee, and J.P. Rothstein, A Comparison of Cold Spray Technique to Single Particle Micro-ballistic Impacts for the Deposition of Polymer Particles on Polymer Substrates, Surf. Coat. Technol., 2018, 351, p 99-107

A. Astarita, L. Boccarusso, M. Durante, A. Viscusi, R. Sansone, and L. Carrino, Study of the Production of a Metallic Coating on Natural Fiber Composite Through the Cold Spray Technique, Mater. Eng. Perform., 2018, 27(2), p 739-750

G. Archambault, B. Jodoin, S. Gaydos, and M. Yandouzi, Metallization of Carbon Fiber Reinforced Polymer Composite by Cold Spray and Lay-Up Molding Processes, Surf. Coat. Technol., 2016, 300, p 78-86

H. Assadi, T. Schmidt, H. Richter, J.-O. Kliemann, K. Binder, F. Gartner, T. Klassen, and H. Kreye, On parameter Selection in Cold Spraying, J. Therm. Spray Technol., 2011, 20(6), p 1161-1176

M. Gardon, A. Latorre, M. Torrell, S. Dosta, J. Fernandez, and J.M. Guilemany, Cold Gas Spray Titanium Coatings Onto a Biocompatible Polymer, Mater. Lett., 2013, 106, p 97-99

A.M. Vilardell, N. Cinca, A. Concustell, S. Dosta, I.G. Cano, and J.M. Guilemany, Cold Spray as an Emerging Technology for Biocompatible and Antibacterial Coatings: State of Art, Mater. Sci., 2015, 50, p 4441-4462

X. Zhou and P. Mohanty, Electrochemical Behavior of Cold Sprayed Hydroxyapatite/Titanium Composite in Hanks’ Solution, Electrochim. Acta, 2012, 65, p 134-140

N. Cinca, A.M. Vilardell, S. Dosta, A. Concustell, I. Garcia Cano, J.M. Guilemany, S. Estrade, A. Ruiz, and F. Peiro, A New Alternative for Obtaining Nanocrystalline Bioactive Coatings: Study of Hydroxyapatite Deposition Mechanisms by Cold Gas Spraying, Am. Ceram. Soc., 2016, 99, p 1420-1428

M. Robotti, S. Dosta, C. Fernandez-Rodriguez, M.J. Hernandez-Rodriguez, I.G. Cano, E.P. Melian, and J.M. Guilemany, Photocatalytic Abatement of NOx by CTiO2/Polymer Composite Coatings Obtained by Low Pressure Cold Gas Spraying, Appl. Surf. Sci., 2016, 362, p 274-280

L. Wang, F. Wang, S. Li, and Y. Wang, Microstructure and Application of Alumina-Supported Cu-Based Coating Prepared by Cold Spray, Surf. Coat. Technol., 2019, 362, p 113-123

M.J. Vucko, P.C. King, A.J. Poole, Y. Hu, M.Z. Jahedi, and R. de Nys, Assessing the Antifouling Properties of Cold-Spray Metal Embedment Using Loading Density Gradients of Metal Particles, Biofouling, 2014, 30, p 651-666

C. Stenson, K.A. McDonnell, S. Yin, B. Aldwell, M. Meyer, D.P. Dowling, and R. Lupoi, Cold Spray Deposition to Prevent Fouling of Polymer Surfaces, Surf. Eng., 2018, 34(3), p 1-11

H. Che, P. Vo, and S. Yue, Investigation of Cold Spray on Polymers by Single Particle ImpactExperiments, Therm. Spray Technol., 2019, 28, p 135-143

P.A. Podrabinnik and I.V. Shishkovsky, Laser Post Annealing of Cold-Sprayed Al-Ni Composite Coatings for Green Energy Tasks, Procedia IUTAM, 2017, 23, p 108-113

F. Robitaille, M. Yandouzi, S. Hind, and B. Jodoin, Metallic Coating of Aerospace Carbon/Epoxy Composites by the Pulsed Gas Dynamic Spraying Process, Surf. Coat. Technol., 2009, 203(19), p 2954-2960

H. Che, M. Gagne, P.S.M. Rajesh, J.E. Sapieha, F. Sirois, D. Therriault, and S. Yue, Metallization of Carbon Fibre Reinforced Polymer for Lightning Strike Protection, Mater. Eng. Perform., 2018, 27(10), p 5205-5211

H. Che, P. Vo, and S. Yue, Metallization of Carbon Fibre Reinforced Polymers by Cold Spray, Surf. Coat. Technol., 2017, 313, p 236-247

H. Che, X. Chu, P. Vo, and S. Yue, Cold Spray of Mixed Metal Powders on Carbon Fibre Reinforced Polymers, Surf. Coat. Technol., 2017, 329, p 232-243

J. Affi, H. Okazaki, M. Yamada, and M. Fukumoto, Fabrication of Aluminum Coating onto CFRP Substrate by Cold Spray, Mater. Trans., 2011, 52(9), p 1759-1763

P.S.M. Rajesh, F. Sirois, and D. Therriault, Damage Response of Composites Coated with Conducting Materials Subjected to Emulated Lightning Strikes, Mater. Des., 2018, 139, p 45-55

R. Kromer, Y. Danlos, E. Aubignat, C. Verdy, and S. Costil, Coating Deposition and Adhesion Enhancements by Laser Surface Texturing—Metallic Particles on Different Classes of Substrates in Cold Spraying Process, Mater. Manuf. Process., 2017, 32(14), p 164

B.K. Pant, A.H.V. Pavan, R.V. Prakash, and M. Kamaraj, Effect of Laser Peening and Shot Peening on Fatigue Striations During FCGR Study of Ti6Al4 V, Int. J. Fatigue, 2016, 93, p 38-50

G.-Q. Chen, Y. Jiao, T.-Y. Tian, X.-H. Zhang, Z.-Q. Li, and W.-L. Zhou, Effect of Wet Shot Peening on Ti-6Al-4 V Alloy Treated by Ceramic Beads, Trans. Nonferrous Metals Soc. China, 2014, 24, p 690-696

R. Ramos, N. Ferreira, J.A.M. Ferreira, C. Capela, and A.C. Batista, Improvement in Fatigue Life of Al 7475-T7351 Alloy Specimens by Applying Ultrasonic and Microshot Peening, Int. J. Fatigue, 2016, 92, p 87-95

H. Kovaci, Y.B. Bozkurt, A.F. Yetim, M. Aslan, and A. Celik, The Effect of Surface Plastic Deformation Produced by Shot Peening on Corrosion Behavior of a Low-Alloy Steel, Surf. Coat. Technol., 2019, 360, p 78-86

Q. Wu, D.-J. Xie, Z.-M. Jia, Y.-D. Zhang, and H.-Z. Zhang, Effect of Shot Peening on Surface Residual Stress Distribution of SiCp/2024Al, Compos. B, 2018, 154, p 382-387

C. Wang, C. Jiang, F. Cai, Y. Zhao, K. Zhu, and Z. Chai, Effect of Shot Peening on the Residual Stresses and Microstructure of Tungsten Cemented Carbide, Mater. Des., 2016, 95, p 159-164

A. Moridi, S.M. Hassani-Gangaraj, S. Vezzu, L. Trsko, and M. Guagliano, Fatigue Behavior of Cold Spray Coatings: The Effect of Conventional and Severe Shot Peening as Pre-/Post-treatment, Surf. Coat. Technol., 2015, 283, p 247-254

X.-T. Luo, Y.-K. Wei, Y. Wang, and C.-J. Li, Microstructure and Mechanical Property of Ti and Ti6Al4V Prepared by an In-Situ Shot Peening Assisted Cold Spraying, Mater. Des., 2015, 85, p 527-533

H. Lee, H. Shin, S. Lee, and K. Ko, Effect of Gas Pressure on Al Coatings by Cold Gas Dynamic Spray, Mater. Lett., 2008, 62(10–11), p 1579-1581

K. Ravi, T. Deplancke, K. Ogawa, J.-Y. Cavaille, and O. Lame, Understanding Deposition Mechanism in Cold Sprayed Ultra High Molecular Weight Polyethylene Coatings on Metals by Isolated Particle Deposition Method, Addit. Manuf., 2018, 21, p 191-200

Z. Khalkhali and J.P. Rothstein, Characterization of the Cold Spray Deposition of a Wide Variety of Polymeric Powders, Surf. Coat. Technol., 2019, 383, p 125251

A.S. Alhulaifi, G.A. Buck, and W.J. Arbegast, Numerical and Experimental Investigation of Cold Spray Gas Dynamic Effects for Polymer Coating, Therm. Spray Technol., 2012, 21, p 852-862

A. Shapiro, The Dynamics and Thermodynamics of Compressible Fluid Flow, The Ronald Press Company, New York, 1953

V.K. Champagne, D.J. Helfritch, S.P.G. Dinavahi, and P.F. Leyman, Theoretical and Experimental Particle Velocity in Cold Spray, Therm. Spray Technol., 2011, 20, p 425-431

Acknowledgments

This research was accomplished through a cooperative research agreement with the US Army Research Laboratory, Contract: W911NF-15-2-0024, P00003 ‘Intelligent Processing of Materials by Design.’ The authors would also like to thank Peter van Puyvelde of KU Leuven for kindly supplying us with the PS, PA, and PU powders used in this study. The contributions from Zimu Zhu who provided the AFM studies are also appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Figure 9 shows the optical microscopy of deposition of HDPE particles (a) on HDPE substrate with smooth surface and (b) on a roughened HDPE surface. The experiment of depositing HDPE particles on a smooth and a roughened surface of HDPE showed that the deposition efficiency was improved by 22% when depositing on a smooth surface compared to depositing on a rough surface of HDPE substrate. This information is not visible the optical images. Rather, the measurement was done by weighing the substrate before an after deposition to calculate the deposition efficiency. Therefore, as a response to the reviewer’s comment, we provided these images in the Appendix not in the results and discussion section.

Rights and permissions

About this article

Cite this article

Khalkhali, Z., Rajan, K.S. & Rothstein, J.P. Peening Effect of Glass Beads in the Cold Spray Deposition of Polymeric Powders. J Therm Spray Tech 29, 657–669 (2020). https://doi.org/10.1007/s11666-020-01001-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01001-0