Abstract

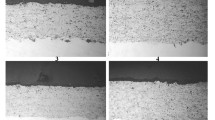

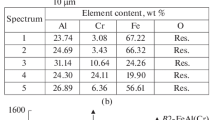

Atmospheric plasma spraying parameters were studied to understand their influence on the splat stacking and the porosity formation in coatings made from commercial Schott 45S5 Bioglass® powder onto AISI 304 L stainless steel substrate. The spraying parameters were established from numerical simulation carried out by the Jets&Poudres software. The plasma spraying was performed by using an Oerlikon Metco F4 MB gun with a 6-mm-internal-diameter nozzle. Three Ar/H2 mixtures were used as plasma-forming gas (95/5, 88/12 and 84/16 vol.%), and the current intensity was varied from 450 to 650 A and the spray distance from 60 to 100 mm. The cooling of the samples during spraying was controlled by air jet pressure. The x-ray diffraction and the scanning electron microscopy were used to determine phases and structural characteristics of coatings, respectively. The numerical simulation results for each set of spray parameters have shown suitable Sommerfeld number for proper splat stacking. However, Na2O and P2O5 evaporation occurred experimentally during spraying of 45S5 Bioglass® promoted the porosity formation into the coating structure. Low porosity was obtained for 45S5 Bioglass coatings manufactured under the appropriate relationship between plasma-forming gas mixture ratio, current intensity, spray distance and cooling air jet pressure to achieve thermal energy input enough to overcome the glass transition temperature and to avoid the evaporation of volatile oxides.

Similar content being viewed by others

References

J.R. Jones et al., Bio-Glasses An Introduction, Wiley, Oxford, 2012, p 1-28

R.B. Heimann et al., Bioceramics Coatings for Medical Implants, Wiley, Weinheim, 2015, p 253-298

L.L. Hench et al., Bonding Mechanisms at the Interface of Ceramic Prosthetic Materials, J. Biomed. Mater. Res., 1971, 5, p 117-141

L.L. Hench et al., Biomaterials: A Forecast for the Future, Biomaterials, 1998, 19, p 1419-1423

A.R. Boccaccini et al., Bioactive Glasses. Fundamentals Technology and Applications, Royal Society of Chemistry, London, 2017, p 1-53

I.D. Xynos et al., Gene-Expression Profiling of Human Osteoblasts Following Treatment with the Ionic Products of Bioglass® 45S5 Dissolution, J. Biomed. Mater. Res., 2001, 55, p 151-157

M. Vollenweider et al., Remineralization of Human Dentin Using Ultrafine Bioactive Glass Particles, Acta Biomater., 2007, 3, p 936-943

L.C. Gerhardt et al., The Pro-angiogenic Properties of Multi-Functional Bioactive Glass Composite Scaffolds, Biomaterials, 2011, 32, p 4096-4108

M.N. Rahaman et al., Bioactive Glass in Tissue Engineering, Acta Biomater., 2011, 7, p 2355-2373

I.D. Thompson et al., Mechanical Properties of Bioactive Glasses, Glass-Ceramics and Composites, Proc. Inst. Mech. Eng. Part H J. Eng. Med., 1998, 212, p 127-136

L.L. Hench, An Introduction to Bioceramics, Imperial College Press, London, 2013

J.Y. Wong et al., Biomaterials, CRC Press, Boca Raton, 2012, p 1-34

H.O. Ylänen et al., Bioactive Glasses—Materials Properties and Applications, Woodhead Publishing Limited, Cambridge, 2011, p 87-116

S. Lopez-Esteban et al., Bioactive Glass Coatings for Orthopedic Metallic Implants, J. Eur. Ceram. Soc., 2003, 23, p 2921-2930

V. Cannillo et al., Different Approaches to Produce Coatings with Bioactive Glasses: Enamelling vs Plasma Spraying, J. Eur. Ceram. Soc., 2010, 30, p 2031-2039

C. Gabbi et al., Bioactive Glass Coating: Physicochemical Aspects and Biological Findings, Biomaterials, 1995, 16, p 515-520

T.M. Lee et al., Characteristics of Plasma-Sprayed Bioactive Glass Coatings on Ti-6A1-4V Alloy: An In-vitro Study, Surf. Coat. Technol., 1996, 79, p 170-177

G. Goller et al., The Effect of Bond Coat on Mechanical Properties of Plasma Sprayed Bioglass-Titanium Coatings, Ceram. Int., 2004, 30, p 351-355

M. Monsalve et al., Bioactivity and Mechanical Properties of Plasma-Sprayed Coatings of Bioglass Powders, Surf. Coat. Technol., 2013, 220, p 60-66

V. López Calvo et al., 45S5 Bioactive Glass Coatings by Atmospheric Plasma Spraying Obtained from Feedstocks Prepared by Different Routes, J. Mater. Sci., 2014, 49, p 7933-7942

M. Monsalve et al., Bioactivity and Mechanical Properties of Bioactive Glass Coatings Fabricated by Flame Spraying, Surf. Coat. Technol., 2015, 268, p 142-146

G. Bolelli et al., Comparison between Suspension Plasma Sprayed and High Velocity Suspension Flame Sprayed Bioactive Coatings, Surf. Coat. Technol., 2015, 280, p 232-249

E. Cañas et al., Effect of Particle Size on Processing of Bioactive Glass Powder for Atmospheric Plasma Spraying, J. Eur. Ceram. Soc., 2016, 36, p 837-845

A.C. Popa et al., Nanomechanical Characterization of Bioglass Films Synthesized by Magnetron Sputtering, Thin Solid Films, 2014, 553, p 166-172

A.C. Popa et al., Superior Biofunctionality of Dental Implant Fixtures Uniformly Coated with Durable Bioglass Films by Magnetron Sputtering, J. Mech. Behav. Biomed. Mater., 2015, 51, p 313-327

A. Balamurugan et al., Electrochemical and Structural Evaluation of Functionally Graded Bioglass-Apatite Composites Electrophoretically Deposited onto Ti-6Al-4V Alloy, Electrochim. Acta, 2009, 54, p 1192-1198

K.P. Ananth et al., Electrophoretic Bilayer Deposition of Zirconia and Reinforced Bioglass System on Ti-6Al-4V for Implant Applications: An in vitro investigation, Mater. Sci. Eng. C, 2013, 3, p 4160-4166

P. Kiran et al., Effective Role of CaO/P2O5 Ratio on SiO2-CaO-P2O5 Glass System, Journal of Advanced Research, 2017, 8, p 279-288

T.H. Qazi et al., Comparison of the Effects of 45S5 and 1303 Bioactive Glass Microparticles on hMSC Behavior, J. Biomed. Mater. Res. Part A, 2017, 10, p 2772-2782

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, 2nd ed., Wiley, Paris, 2008, p 167-219

A. Cattini, Coatings of Bioactive Glasses and Hydroxyapatite and Their Properties, University of Limoges and University of Modena and Reggio Emilia, Limoges, 2013, p 1-122

A.R. Boccaccini et al., Bioactive Glasses. Fundamentals Technology and Applications, Royal Society of Chemistry, London, 2017, p 169-173

J.A. Epinette et al., Fifteen Years of Clinical Experience with Hydroxyapatite Coatings in Joint Arthroplasty, Springer, Paris, 2004, p 1-24

P.L. Fauchais et al., Thermal Spray Fundamentals, Springer, New York, 2014, p 807-980

G. Delluc et al., Jet & Poudres, Université de Limoges, Limoges, 2003

M. Vicent et al., Preparation of High Solids content Nano-Titania Suspensions to Obtain Spray-Dried Nanostructured Powders for Atmospheric Plasma Spraying, J. Eur. Ceram. Soc., 2012, 32, p 185-194

E. Sánchez et al., Preparation and Spray Drying of Al2O3-TiO2 nanoparticle suspensions to obtain nanostructured coatings by APS, Surf. Coat. Technol., 2010, 205, p 987-992

L. Strmungsmechanik et al., Droplet-Wall Collisions: Experimental Studies of the Deformation and Breakup Process, Int. J. Multiph. Flow, 1995, 21, p 151-173

S. Chandra et al., Formation of Solid Splats During Thermal Spray Deposition, ASM Int., 2009, 18, p 148-180

H. Copete et al., Improvement of the Adhesion on Hydroxyapatite Coatings Produced by Oxyfuel Thermal Spray from Results of Numerical Simulation • Mejoramiento de la Adherencia en Recubrimientos de Hidroxiapatita Elaborados Mediante Proyección Térmica Oxiacetilénica, DYNA, 2017, 84, p 170-176

K. Mori et al., Charge States of Ca Atoms in β-Dicalcium Silicate, J. Solid State Chem., 2006, 179, p 3286-3294

J. Qian et al., Fabrication and Characterization of Biomorphic 45S5 Bioglass Scaffold from Sugarcane, Mater. Sci. Eng. C, 2009, 29, p 1361-1364

M. Khorami et al., In-vitro Bioactivity and Biocompatibility of Lithium Substituted 45S5 Bioglass, Mater. Sci. Eng. C, 2011, 31, p 1584-1592

O. Bretcanu et al., Sintering and Crystallisation of 45S5 Bioglass® Powder, J. Eur. Ceram. Soc., 2009, 29, p 3299-3306

X. Chatzistavrou et al., Following Bioactive Glass Behavior Beyond Melting Temperature by Thermal and Optical Methods, Phys. Status Solidi, 2004, 201, p 944-951

J.M. Oliveira et al., Effects of Si Speciation on the In-vitro Bioactivity of Glasses, Biomaterials, 2002, 23, p 371-379

M. Mozafari et al., Applied Surface Science Biomimetic Formation of Apatite on the Surface of Porous Gelatin/Bioactive Glass Nanocomposite Scaffolds, Appl. Surf. Sci., 2010, 257, p 1740-1749

H. Peterlik et al., Structural Characterization of Gel-Derived Calcium Silicate Systems, J. Phys. Chem. A, 2010, 114, p 10403-10411

Z. Gou et al., Synthesis and In-vitro Bioactivity of Dicalcium Silicate Powders, J. Eur. Ceram. Soc., 2004, 24, p 93-99

Z. Gou et al., Preparation and Characterization of Novel Bioactive Dicalcium Silicate Ceramics, J. Eur. Ceram. Soc., 2005, 25, p 1507-1514

A. Dey et al., Development of Hydroxyapatite Coating by Microplasma Spraying, Mater. Manuf. Process., 2009, 24, p 1321-1330

T. Poirier et al., Formation of Hollow Vitreous and Semi-Crystalline Microspheres in Slag Flame Spraying, Ceram. Int., 2014, 41, p 369-377

L.L. Hench, The Story of Bioglass®, J. Mater. Sci. Mater. Med., 2006, 17, p 967-978

Acknowledgments

The authors want to acknowledge financial support from COLCIENCIAS—the Administrative Department of Science, Technology and Innovation (727 doctoral scholarship and code Project 1115745-57862), Limousin Administrative Region and University of Limoges for Cotutelle Scholarship. Authors many thank Dayana Meza, Eloïse Hyvernaud and Richard Mayet for their help in the SEM and XRD characterizations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited paper selected from presentations at the 2019 International Thermal Spray Conference, held May 26-29, 2019 in Yokohama, Japan and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Rojas, O., Prudent, M., López, M.E. et al. Influence of Atmospheric Plasma Spraying Parameters on Porosity Formation in Coatings Manufactured from 45S5 Bioglass® powder. J Therm Spray Tech 29, 185–198 (2020). https://doi.org/10.1007/s11666-019-00952-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00952-3