Abstract

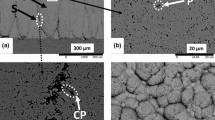

Effects of the ceramic powder size used for suspension as well as several processing parameters in suspension plasma spraying of YSZ were investigated experimentally, aiming to fabricate highly segmented microstructures for thermal barrier coating (TBC) applications. Particle image velocimetry (PIV) was used to observe the atomization process and the velocity distribution of atomized droplets and ceramic particles travelling toward the substrates. The tested parameters included the secondary plasma gas (He versus H2), suspension injection flow rate, and substrate surface roughness. Results indicated that a plasma jet with a relatively higher content of He or H2 as the secondary plasma gas was critical to produce highly segmented YSZ TBCs with a crack density up to ~12 cracks/mm. The optimized suspension flow rate played an important role to realize coatings with a reduced porosity level and improved adhesion. An increased powder size and higher operation power level were beneficial for the formation of highly segmented coatings onto substrates with a wider range of surface roughness.

Similar content being viewed by others

References

N.P. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296, p 280-284

R. Vassen, M. Jarligo, T. Steinke, D.E. Mack, and D. Stöver, Overview on Advanced Thermal Barrier Coatings, Surf. Coat. Technol., 2010, 205, p 938-942

X.Q. Cao, R. Vassen, and D. Stöver, Ceramic Materials for Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2004, 24, p 1-10

D.R. Clarke and S.R. Phillpot, Thermal Barrier Coating Materials, Mater. Today, 2005, 8, p 22-29

D.R. Clarke, M. Oechsner, and N.P. Padture, Thermal-Barrier Coatings for More Efficient Gas-Turbine Engines, MRS Bull., 2012, 37, p 891-898

S. Sampath, U. Schulz, M.O. Jarligo, and S. Kuroda, Processing Science of Advanced Thermal-Barrier Systems, MRS Bull., 2012, 37, p 903-910

H.B. Guo, R. Vaßen, and D. Stöver, Atmospheric Plasma Sprayed Thick Thermal Barrier Coatings with High Segmentation Crack Density, Surf. Coat. Technol., 2004, 186(3), p 353-363

M. Karger, R. Vaßen, and D. Stöver, Atmospheric Plasma Sprayed Thermal Barrier Coatings with High Segmentation Crack Densities: Spraying Process, Microstructure and Thermal Cycling Behavior, Surf. Coat. Technol., 2011, 206(1), p 16-23

P. Fauchais, Understanding Plasma Spraying, J. Phys. D Appl. Phys., 2004, 37, p R86-106

P. Fauchais, R. Etchart-Salas, V. Rat, J.F. Coudert, N. Caron, and K. Wittmann-Ténèze, Parameters Controlling Liquid Plasma Spraying: Solutions, Sols, or Suspensions, J. Therm. Spray Technol., 2008, 7(1), p 31-59

P. Fauchais, V. Rat, J.-F. Coudert, R. Etchart-Salas, and G. Montavon, Operating Parameters for Suspension and Solution Plasma-Spray Coatings, Surf. Coat. Technol., 2008, 202, p 4309-4317

P. Blazdell and S. Kuroda, Plasma Spraying of Submicron Ceramic Suspensions Using a Continuous Ink Jet Printer, Surf. Coat. Technol., 2000, 123, p 239-246

A. Joulia, W. Duarte, S. Goutier, M. Vardelle, A. Vardelle, and S. Rossignol, Tailoring the Spray Conditions for Suspension Plasma Spraying, J. Therm. Spray Technol., 2014, 24(1-2), p 24-29

K. VanEvery, M.J.M. Krane, R.W. Trice, H. Wang, W. Porter, W. Besser, D. Sordelet, I. Llavsky, and J. Almer, Column Formation in Suspension Plasma Sprayed Coating and Resultant Thermal Properties, J. Therm. Spray Technol., 2011, 20, p 817-828

N. Curry, Z. Tang, N. Markocsan, and P. Nylén, Influence of Bond Coat Surface Roughness on the Structure of Axial Suspension Plasma Spray Thermal Barrier Coatings-Thermal and Lifetime Performance, Surf. Coat. Technol., 2015, 268, p 15-23

P. Sokołowski, S. Kozerski, L. Pawłowski, and A. Ambroziak, The Key Process Parameters Influencing Formation of Columnar Microstructure in Suspension Plasma Sprayed Zirconia Coatings, Surf. Coat. Technol., 2014, 260, p 97-106

B. Bernarda, L. Bianchia, A. Maliéb, A. Jouliac, and B. Rémyd, Columnar Suspension Plasma Sprayed Coating Microstructural Control for Thermal Barrier Coating Application, J. Eur. Ceram. Soc., 2016, 36(4), p 1081-1089

M. Marr and O. Kesler, Influence of Plasma Heat Flux on Segmentation Cracking and Permeability of Thin Suspension Plasma Sprayed Coatings, Surf. Coat. Technol., 2013, 216, p 289-296

Y. Zhao, D. Li, X. Zhong, H. Zhao, L. Wang, F. Shao, C. Liu, and S. Tao, Thermal Shock Behaviors of YSZ Thick Thermal Barrier Coatings Fabricated by Suspension and Atmospheric Plasma Spraying, Surf. Coat. Technol., 2014, 249, p 48-55

A. Guignard, G. Mauer, R. Vassen, and D. Stöver, Deposition and Characteristics of Submicrometer Structured Thermal Barrier Coatings by Suspension Plasma Spraying, J. Therm. Spray Technol., 2012, 21(3-4), p 416-424

H. Kaßner, R. Siegert, D. Hathiramani, R. Vaßen, and D. Stöver, Application of Suspension Plasma Spraying (SPS) for Manufacture of Ceramic Coatings, J. Therm. Spray Technol., 2008, 17(1), p 115-123

S. Kuroda, M. Watanabe, K. Kim, and H. Katanoda, Current Status and Future Prospects of Warm Spray Technology, J. Therm. Spray Technol., 2011, 20(4), p 653-676

J. Oberste Berghaus, S. Bouaricha, J.-G. Legoux, and C. Moreau, Injection Conditions and In-Flight Particle States in Suspension Plasma Spraying of Alumina and Zirconia Nano-Ceramics, International Thermal Spray Conference, C. Berndt, E. Lugsheider, Ed., ASM International, Basel, 2005, p 512-518

U. Schulz and M. Schmücker, Microstructure of ZrO2 Thermal Barrier Coatings Applied by EB-PVD, Mater. Sci. Eng. A, 2000, 276, p 1-8

T.A. Taylor, U.S. Patent 5, 073, 433, 1989

S. Sampath, X.Y. Jiang, J. Matejicek, A.C. Leger, and A. Vardelle, Substrate Temperature Effects on Splat Formation, Microstructure Development and Properties of Plasma Sprayed Coatings. Part I: Case Study for Partially Stabilized Zirconia, Mater. Sci. Eng. A, 1999, 272, p 181-188

P. Bengtsson and C. Persson, Modelled and Measured Residual Stresses in Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 1997, 92, p 78-86

Acknowledgments

The authors thank Mr. Hiraoka for the SPS coatings preparation. Thanks also to Prof. A. Vardelle and Prof. M. Vardelle for their valuable discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Honda, H., Kuroda, S. et al. Highly Segmented Thermal Barrier Coatings Deposited by Suspension Plasma Spray: Effects of Spray Process on Microstructure. J Therm Spray Tech 25, 1638–1649 (2016). https://doi.org/10.1007/s11666-016-0469-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0469-6