Abstract

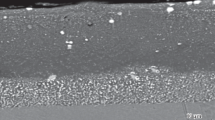

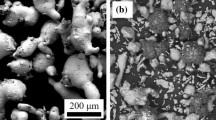

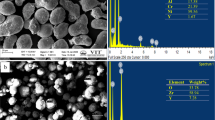

Tribological tests were conducted on thermally sprayed silicon carbide (SiC) coatings to investigate its potential on reducing wear in offshore wind turbine bearings. The tests were carried out under dry conditions, 3.5 wt.% NaCl solution, and polyalfaolefin (PAO)-lubricated conditions. In order to obtain good quality SiC coatings, it is compulsory to modify the feedstock to limit SiC decomposition during atmospheric spraying process. The SiC feedstock used in this research has been modified with yttrium aluminum garnet (Y3Al5O12) oxide additives that originated from its metal salt precursors. High-frequency pulse detonation (HFPD) technique has been utilized to produce coatings of around 100 μm in thickness. The sliding tests have recorded the lowest coefficient of friction (COF) of 0.15 in PAO condition and the highest COF of 0.50 in dry sliding. The wear tracks morphology show that during dry sliding test, the coatings experience abrasive wear accompanied by tribo-oxidation reaction that initiates crack formation along the splat boundaries. On the other two sliding test conditions (NaCl and PAO), polishing of asperities and some grain plowing from the splats were observed in the wear tracks. Tribochemical wear was found to be the main mechanism producing smooth surfaces. Nevertheless, in all cases, the wear losses were negligible.

Similar content being viewed by others

References

M.N. Kotzalas and G.L. Doll, Tribological Advancements for Reliable Wind Turbine Performance, Philos. Trans. R. Soc. A, 2010, 368(1929), p 4829-4850

G.L. Doll, C.R. Ribaudo, and R.D. Evans, Engineered Surfaces for Steel Rolling Element Bearings and Gear, MS&T Conference Proceedings, Curran Associates, Inc., 2004

H. Heshmat, P. Hryniewicz, J.F. Walton, J.P. Willis, S. Jahanmir, and C. DellaCorte, Low-Friction Wear-Resistant Coatings for High-Temperature Foil Bearings, Tribol. Int., 2005, 38(11-12), p 1059-1075

R.D. Evans, E.P. Cooke, C.R. Ribaudo, and G.L. Doll, Nanocomposite Tribological Coatings for Rolling Element Bearings, Mater. Res. Soc. Symp. Proc., 2003, 750, p 407-417

R.B. Heimann and H.D. Lehmann, Recently Patented Work on Thermally Sprayed Coatings for Protection Against Wear and Corrosion of Engineered Structures, Recent Patents on Materials Science, 2008, p 41-55

S. Stewart and R. Ahmed, Rolling Contact Fatigue of Surface Coatings—A Review, Wear, 2002, 253(11-12), p 1132-1144

X. Zhang, F. Xuan, S. Tu, B. Xu, and Y. Wu, Durability of Plasma-Sprayed Cr3C2-NiCr Coatings Under Rolling Contact Conditions, Front. Mech. Eng., 2011, 6(1), p 118-135

K. Miyoshi and D. Buckley, Anisotropic Tribological Properties of SiC, Wear, 1982, 75(2), p 253-268

J. Takadoum, Z. Zsiga, and C. Roques-Carmes, Wear Mechanism of Silicon Carbide: New Observations, Wear, 1994, 174(1-2), p 239-242

D.E. Deckman, C.I. Chen, and S.M. Hsu, Effect of Selected Chemical Compounds on the Lubrication of Silicon Carbide, Tribol. Trans., 1999, 42(3), p 619-625

F.-W. Bach, K. Möhwald, and B. Drößler, Development of a Technique for Hard Coating of Component Parts by Synthesis of Silicon Carbide in Thermal Spray Processes, Thermal Spray 2005: Thermal Spray connects: Explore its surfacing potential!, E. Lugscheider, Ed., DVS-ASM International, 2005, p 1099-1104

B. Wielage, J. Wilden, T. Schnick, A. Wank, J. Beczkowiak, R. Schülein, H. Zoz, and H. Ren, Mechanically Alloyed SiC Composite Powders for HVOF Applications, International Thermal Spray Conference (ITSC 2002), E. Lugscheider and C.C. Berndt, Ed., March 4-6, 2002 (Essen, Germany), DVS Deutscher Verband für Schweißen, 2002, p 1061

B. Wielage, T. Grund, M. Nebelung, S. Thiele, A. Wank, and A. Schwenk, Development and Investigation of SiC-Based Thermal Spray Powders with Alumina-Yttria Binder Matrix, Thermal Spray 2007: Global Coating Solutions, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon Ed., ASM International, Materials Park, OH, 2007, p 1140-1144

M. Tului, B. Giambi, S. Lionetti, G. Pulci, F. Sarasini, and T. Valente, Silicon Carbide Based Plasma Sprayed Coatings, Surf. Coat. Technol., 2012, 207, p 182-189

F. Mubarok and N. Espallargas, Thermally Sprayed Ceramic Materials, IPO-UK, GB1219642.4, 2012

N. Zhang, H. Ru, X. Sun, and Q. Cai, A Coprecipitation Coating Synthesis of SiC/YAG Composites, J. Mater. Sci. Technol., 2004, 20(3), p 323-326

I. Fagoaga, G. Barykin, J. de Juan, T. Soroa, and C. Vaquero, The High Frequency Pulse Detonation (HFPD) Spray Process, Tagungsband Conference Proceedings (2nd UTSC 1999), E. Lugscheider and R.A. Kammer, Ed., March 17-19, 1999 (Düsseldorf, Germany), DVS Deutscher Verband für Schweißen, 1999, p 879

J. Nerz, B. Kushner, and A. Rotolico, Microstructural Evaluation of Tungsten Carbide-Cobalt Coatings, J. Therm. Spray Technol., 1992, 1(2), p 147-152

O. Borrero-López, A.L. Ortiz, F. Guiberteau, and N.P. Padture, Effect of Microstructure on Sliding-Wear Properties of Liquid-Phase-Sintered α-SiC, J. Am. Ceram. Soc., 2005, 88(8), p 2159-2163

M. Matsuda, K. Kato, and A. Hashimoto, Friction and Wear Properties of Silicon Carbide in Water from Different Sources, Tribol. Lett., 2011, 43(1), p 33-41

P. Andersson and A. Blomberg, Instability in the Tribochemical Wear of Silicon Carbide in Unlubricated Sliding Contacts, Wear, 1994, 174(1-2), p 1-7

Acknowledgments

The authors would like to acknowledge the support of TSO Materialer, NTNU (Strategic Area of Materials, NTNU) for funding. Carlos Vaquero and Georgii Barykin (TECNALIA, Spain) are also thanked for helping and advising in the production of the coatings.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 5th Asian Thermal Spray Conference (ATSC 2012) and has been expanded from the original presentation. ATSC 2012 was held at the Tsukuba International Congress Center, Ibaraki, Japan, November 26-28, 2012, and was organized by the Japan Thermal Spray Society and the Asian Thermal Spray Society.

Rights and permissions

About this article

Cite this article

Mubarok, F., Armada, S., Fagoaga, I. et al. Thermally Sprayed SiC Coatings for Offshore Wind Turbine Bearing Applications. J Therm Spray Tech 22, 1303–1309 (2013). https://doi.org/10.1007/s11666-013-9991-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9991-y