Abstract

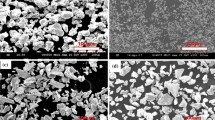

Copper-based composites for thermal conductive components were prepared via the cold spray process, and the deposition efficiency and adhesion morphology of feedstock powders on Cu substrate were evaluated. Cu-based composites were fabricated using Cu-Cr mixed powders with their mixture ratio of 20, 35, 50, and 65 mass% Cr onto oxygen-free copper substrate with N2 carrier gas. Cu-Cr composite coatings were investigated for their Cr content ratio, microstructures, and thermal conductivity. The Cr content ratio in the coating was approximately 50-60% of feedstock mixture ratio due to the low formability of the hard particles. Transmission electron microscopy characterizations revealed that an oxygen-rich layer exists at the Cr particle/Cu substrate interface, which contributes to the deposition of the Cr particles. After the heat treatment at 1093 K, the coatings showed denser cross-sectional structures than those before the heat treatment, and the thermal conductivity was improved as a result of the recrystallization of Cu matrix.

Similar content being viewed by others

References

K. Sakaki, Promising Field in New Thermal Spray Technology “Cold Spray”, J. Jpn. Therm. Spray. Soc., 2010, 47, p 113-119

J. Vlcek, L. Gimeno, H. Huber, and E. Lugscheider, A Systematic Approach to Material Eligibility for the Cold Spray Process, Thermal Spray 2003; Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Eds., May 5-8, 2003 (Orlando, FL), ASM International, 2003, p 37-44

H. Kang and S.B. Kang, Tungsten/Copper Composite Deposits Produced by a Cold Spray, Scr. Mater., 2003, 49, p 1169-1174

F. Sevillano, P. Poza, C.J. Munez, S. Vezzu, S. Rech, and A. Trentin, Influence of the Powder Morphology and Alumina Content in Cold-Sprayed Ni-Al2O3 Coating, International Thermal Spray Conference & Exposition 2011, Sep 27-29, 2011 (Hamburg, Germany), DVS Media, 2011, p 373-378

K. Mihara, Y. Ohyama, and H. Suzuki, Development of Cu-Cr In-Situ Composite, J. Jpn. Copp. Brass Res. Assoc., 2000, 39, p 227-232

D. Ulmer, Application of Oxidation/Corrosion Resistant Coatings to Rocket Engine Combustion Chamber Liners Using Kinetic Metallization, AeroMat 2004 Conf., Seattle, WA, Jun 2004

W.-Y. Li and C.-J. Li, Effect of Annealing Treatment on the Microstructure and Properties of Cold-Sprayed Cu Coatings, Thermal Spray 2005: Explore Its Surfacing Potential!, E. Ligscheider, Ed., May 2-4, 2005 (Basel, Switzerland), AMS International, 2005, p 1258-1263

J. Lagerbom, H. Makinen, and P. Vuoristo, Effect of Heat Treatment on Properties of Cold Sprayed Coatings, Thermal Spray 2005: Explore its surfacing potential!, E. Ligscheider, Ed., May 2-4, 2005 (Basel, Switzerland), AMS International, 2005, p 240-244

K.H. Kim, M. Watanabe, S. Kuroda, and N. Kawano, Observation of High Resolution Microstructures in Thermal Sprayed Coatings and Single Deposited Splats Using Ion Beam Milling, Mater. Trans., 2011, 52, p 439-446

H. Fukanuma and R. Huang, Development of High Pressure and Temperature Cold Spray System and the Current of its Application, Funct. Mater., 2009, 29, p 35-44

D. Zhang, P.H. Shipway, and D.G. McCartney, Particle-Substrate Interactions in Cold Gas Dynamic Spraying, Thermal Spray 2003; Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Eds., May 5-8, 2003 (Orlando, FL), ASM International, 2003, p 45-52

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfricht, Adiabatic Shear Instability Based Mechanism for Particle/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25, p 681-688

H. Assadi, F. Gaertner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Spraying, Acta Mater., 2003, 51, p 4379-4394

K.H. Kim and S. Kuroda, Amorphous Oxide Film Formed by Dynamic Oxidation During Kinetic Spraying of Titanium at High Temperature and Its Role in Subsequent Coating Formation, Scr. Mater., 2010, 63, p 215-218

M. Fukumoto, Particle Deposition Mechanism in Both Thermal Spray and Cold Spray, Funct. Mater., 2009, 29, p 24-34

W.Y. Li, C. Zhang, H.-T. Wang, X.P. Guo, H.L. Liao, C.-J. Li, and C. Coddet, Significant Influences of Metal Reactivity and Oxide Films at Particle Surfaces on Coating Microstructure in Cold Spraying, Appl. Surf. Sci., 2007, 253, p 3557-3562

E. Calla, D.G. McCartney, and P.H. Shipway, Effect of Heat Treatment on the Structure and Properties of Sprayed Copper, Thermal Spray 2005: Explore Its Surfacing Potential!, E. Ligscheider, Ed., May 2-4, 2005 (Basel, Switzerland), AMS International, 2005, p 170-176

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kikuchi, S., Yoshino, S., Yamada, M. et al. Microstructures and Thermal Properties of Cold-Sprayed Cu-Cr Composite Coatings. J Therm Spray Tech 22, 926–931 (2013). https://doi.org/10.1007/s11666-013-9926-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9926-7