Abstract

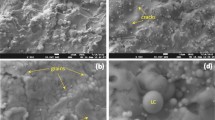

High Cr content Ni-Cr-Ti arc-spray coatings have proven successful in resisting the high temperature sulfidizing conditions found in black liquor recovery boilers in the pulp and paper industry. The corrosion resistance of the coatings is dependent upon the coating composition, to form chromium sulfides and oxides to seal the coating, and on the coating microstructure. Selection of the arc-spray parameters influences the size, temperature and velocity of the molten droplets generated during spraying, which in turn dictates the coating composition and formation of the critical coating microstructural features—splat size, porosity and oxide content. Hence it is critical to optimize the arc-spray parameters in order to maximize the corrosion resistance of the coating. In this work the effect of key spray parameters (current, voltage, spray distance and gas atomizing pressure) on the coating splat thickness, porosity content, oxide content, microhardness, thickness, and surface profile were investigated using a full factorial design of experiment. Based on these results a set of oxidized, porous and optimized coatings were prepared and characterized in detail for follow-up corrosion testing.

Similar content being viewed by others

References

Technical Bulletin 2.3.19-Metallisation Wire 88E—Nickel Based Boiler Alloy (Issue 8/99)

Technical Data Bulletin—Praxair and TAFA TAFALOY 45CT Wire (File 1.9.1.2-45CT Issue 010928), 2000

R. Luding, R. Thorpe, and R.V. Hinckley, The Development of Twin Wire Arc and HP/HVOF Sprayed Coatings for Coal-Fired Steam Generation Boiler, Adv. Mater. Process., 2010, 168(2), p 34-36

W. Zanchuk, The Use of Tafaloy 45CT, an Ni-Cr-Ti Alloy as an Arc Sprayed Corrosion Barrier in High Temperature Sulfurous Environments, Surf. Coat. Technol., 1989, 39(40), p 65-69

C.R. Hubbard, R.A. Peascoe, and J.R. Keiser, Pulp and Paper Plant Materials Issues Addressed by X-ray and Neutron Diffraction Methods, Adv. X-ray Anal., 2003, 46, p 278-284

R.A. Peascoe, J.R. Keiser, J.G. Hemrick, M.P. Brady, P. Sachenko, C.R. Hubbard, R.D. Ott, C.A. Blue, and J.P. Gorog, Materials Issues in High Temperature Black Liquor Gasification, TAPPI Fall Technical Conference, 2003, p 5037-5045

S. Al-Hassan, P.M. Singh, and G.J. Fonder, Effect of Smelt/Gas Interaction on SA-210 Carbon Steel Corrosion, Proceedings of the 1998 International Chemical Recovery Conference, June 1-4, 1998, Institute of Paper Science and Technology, p 901-908

W.B.A. Sharp, Corrosion and Cracking in Recovery Boilers, TAPPI Kraft Recovery Course 2007, January 8-11, 2007, p 729-759

G.E.P. Box, W.G. Hunter, and J.S. Hunter, Statistics for Experimenters—An Introduction to Design, Data Analysis and Model Building, Wiley, Hoboken, 1978

M. Axente and V. Geamăn, Characterization of Ni-5Al and Sprasteel Coatings Deposited by Electric Arc Wire Thermal Spraying, Metal. Int., 2011, 16(5), p 89-92

K. Cooke, G. Oliver, V. Buchanan, and N. Palmer, Optimization of the Electric Wire Arc-Spraying Process for Improved Wear Resistance of Sugar Mill Roller Shells, Surf. Coat. Technol., 2007, 202(1), p 185-188

S. Dallaire, H. Levert, and J.G. Legoux, Erosion Resistance of Arc-Sprayed Coatings to Iron Ore at 25 and 315 °C, J. Therm. Spray Technol., 2001, 10(2), p 337-350

G. Jandin, H. Liao, Z.Q. Feng, and C. Coddet, Correlations Between Operating Conditions, Microstructure and Mechanical Properties of Twin Wire Arc Sprayed Steel Coatings, Mater. Sci. Eng., A, 2003, 349(1-2), p 298-305

M.P. Planche, H. Liao, and C. Coddet, Relationships Between In-Flight Particle Characteristics and Coating Microstructure with a Twin Wire Arc Spray Process and Different Working Conditions, Surf. Coat. Technol., 2004, 182(2-3), p 215-226

H.D. Steffens and K. Nassenstein, Influence of the Spray Velocity on Arc-Sprayed Coating Structures, J. Therm. Spray Technol., 1999, 8(3), p 454-460

D.J. Varacalle, G.C. Wilson, R.W. Johnson, T.J. Steeper, G. Irons, W.R. Kratochvil, and W.L. Riggs, Taguchi Experimental Design Study of Twin-Wire Electric Arc Sprayed Aluminum Coatings, J. Therm. Spray Technol., 1994, 3(1), p 69-74

D.J. Varacalle, Jr., D.P. Zeek, V. Zanchuck, E. Sampson, K.W. Couch, D. Benson, and G.S. Cox, Experimental Studies of Twin-Wire Electric Arc Sprayed Zinc/Aluminum Alloy Coatings, J. Therm. Spray Technol., 1998, 7(4), p 513-520

T. Watanabe, X. Wang, E. Pfender, and J. Heberlein, Correlations Between Electrode Phenomena and Coating Properties in Wire Arc Spraying, Thin Solid Films, 1998, 316(1-2), p 169-173

J. Wilden, J.P. Bergmann, S. Jahn, S. Knapp, F. Rodijnen, and G. Fischer, Investigation about the Chrome Steel Wire Arc Spray Process and the Resulting Coating Properties, J. Therm. Spray Technol., 2007, 16(5-6), p 759-767

W.S. Rasband, ImageJ, US National Institute of Health, http://imagej.nih.gov/ij/, p 1997-2012

I. Gedzevicius and A.V. Valiulis, Analysis of Wire Arc Spraying Process Variables on Coatings Properties, J. Mater. Process. Technol., 2006, 175(1-3), p 206-211

N. Lebrun, Cr-Ni-Ti (Chromium-Nickel-Titanium), Light Metal Ternary Systems: Phase Diagrams, Crystallographic and Thermodynamic Data, G. Effenberg and S. Ilyenko, Ed., Springer, Berlin, 2008,

R.J. Damani and P. Makroczy, Heat Treatment Induced Phase and Microstructural Development in Bulk Plasma Sprayed Alumina, J. Eur. Ceram. Soc., 2000, 20, p 867-888

I. Levin and D. Brandon, Metastable Alumina Polymorphs: Crystal Structures and Transition Sequences, J. Am. Ceram. Soc., 1998, 81(8), p 1995-2012

R. McPherson, On the Formation of Thermally Sprayed Alumina Coatings, J. Mater. Sci., 1980, 15, p 3141-3149

X. Wang, J. Heberlein, E. Pfender, and W. Gerberich, Effect of Nozzle Configuration, Gas Pressure, and Gas Type on Coating Properties in Wire Arc Spray, J. Therm. Spray Technol., 1999, 8(4), p 565-575

A.P. Newbury and P.S. Grant, Oxidation During Electric Arc Spray Forming of Steel, J. Mater. Process. Technol., 2006, 178, p 259-269

A.P. Newbury and P.S. Grant, Droplet Splashing During Arc Spraying of Steel and the Effect on Deposit Microstructure, J. Therm. Spray Technol., 2000, 9(2), p 250-258

D. Young, High Temperature Oxidation and Corrosion of Metals, Elsevier Corrosion Series, T. Burstein, Ed., Elsevier, Oxford, 2008

T.M. Besmann, N.S. Kulkarni, and K.E. Spear, Thermochemical Analysis and Modeling of the Al2O3-Cr2O3, Cr2O3-SiO2 and Al2O3-Cr2O3-SiO2 Systems Relevant to Refractories, J. Am. Ceram. Soc., 2006, 89(2), p 638-644

S. Somiya, S. Hirano, and S. Kamiya, Phase Relations of the Cr2O3-TiO2 System, J. Solid State Chem., 1978, 25, p 273-284

K. El-Menshawy, H.P. Buchkremer, F. Tietz, and D. Stoever, Electrical Conductivity of Sintered Chromia Mixed with TiO2, CuO and Mn-Oxides, J. Mater. Sci. Technol., 2006, 22(2), p 245-251

H. Nagai and K. Ohbayashi, Effect of TiO2 on the Sintering and the Electrical Conductivity of Cr2O3, J. Am. Ceram. Soc., 1989, 72(3), p 400-403

H. Nagai and M. Okabayashi, Deleterious Effect of Ti Addition on the Oxidation Resistance of Ni-20Cr Alloy, Trans. Jpn. Inst. Met., 1981, 22(10), p 691-698

H. Nagai, M. Okabayashi, and T. Murakami, High Temperature Oxidation of Ni-20Cr-xTiO2 Alloys, Trans. Jpn. Inst. Met., 1982, 23(8), p 473-479

S. Deshpande, S. Sampath, and H. Zhang, Mechanisms of Oxidation and Its Role in Microstructural Evolution of Metallic Thermal Spray Coatings—Case Study for Ni-Al, Surf. Coat. Technol., 2006, 200, p 5396-5406

R.A. Neiser, M.F. Smith, and R.C. Dykhuizen, Oxidation in Wire HVOF-Sprayed Steel, J. Therm. Spray Technol., 1998, 7(4), p 537-545

H. Okamoto, Ni-O (Nitrogen-Oxygen), JPE, 1997, 18(4), p 404

G.H. Aylward and T.J.V. Findlay, SI, Chemical Data, 2nd ed., Wiley, Australasia Pty. Ltd, New York, 1971

A.P. Newbury, P.S. Grant, and R.A. Neiser, The Velocity and Temperature of Steel Droplets During Electric Arc Spraying, Surf. Coat. Technol., 2005, 195, p 91-101

S. Matthews and M. Schweizer, High Temperature Oxidation and Smelt Deposit Corrosion of Ni-Cr-Ti Arc-Sprayed Coatings, J. Therm. Spray Technol. (this issue)

Acknowledgments

The authors are thankful for the valuable information and support provided by Warren Blakemore on the operation and maintenance of black liquor recovery boilers. The support from Holster Engineering Ltd (NZ) in spraying the coatings for this work is also gratefully acknowledged. The support provided by Professor Margaret Hyland in facilitating this work is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matthews, S., Schweizer, M. Optimization of Arc-Sprayed Ni-Cr-Ti Coatings for High Temperature Corrosion Applications. J Therm Spray Tech 22, 538–550 (2013). https://doi.org/10.1007/s11666-013-9914-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9914-y