Abstract

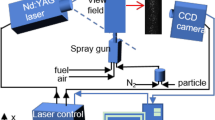

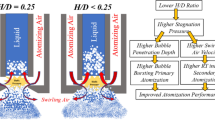

The formation of single splats is the foundation for any thermal spray coating. Therefore, this study focuses on the investigation of single splat morphologies to determine the influence of spray parameters on the morphological distribution of particles inside the flame. A new method to create a footprint of a spray jet with an extremely short exposure time was used. The resulting field of splats enabled the assignment of each splat to its radial position in the spray jet. The footprints were analyzed and the quantities and morphologies of the splats were correlated to particle in-flight measurements and coating properties. A strong correlation between the particle velocity, the percentage of the so-called pancake-like splats, and the porosity of the coating could be revealed. The influence of the particle temperature was found to be of minor importance to the splat form and the porosity of the coatings. Still, the particle temperature had a good correlation with the coating hardness and the dissolving of the WC. Measurements of the splat size in different areas of the footprints revealed that the percentage of splats larger than 40 μm in diameter was generally higher in the center of the footprint than in the outer regions.

Similar content being viewed by others

References

T. Sahraoui, S. Guessasma, M. Jeridane et al., HVOF Sprayed WC-Co Coatings: Microstructure, Mechanical Properties and Friction Moment Prediction, Mater. Des., 2010, 31(3), p 1431-1437

D.A. Stewart, P.H. Shipway, and D.G. McCartney, Abrasive Wear Behavior of Conventional and Nanocomposite HVOF-Sprayed WC-Co Coatings, Wear, 1999, 225-229(2), p 789-798

J. He and J.M. Schoenung, A Review on Nanostructured WC-Co Coatings, Surf. Coat. Technol., 2002, 157, p 72-79

S. Zimmermann, W. Tillmann, E. Vogli et al., Supervision and Measuring of Particle Parameters During the Wire-Arc Spraying Process with the Diagnostic System Accuraspray-g3 and LDA, J. Therm. Spray Technol., 2010, 19, p 745-755

J.A. Picas, M. Punset, M.T. Baile, et al., Effect of Oxygen/Fuel Ratio on the In-Flight Particle Parameters and Properties of HVOF WC-CoCr Coatings, Surf. Coat. Technol., 2011, 205(2), p 364-368

A. Elsebaei, J. Heberlein, M. Elshaer et al., Comparison of In-Flight Particle Properties, Splat Formation and Coating Microstructure for Regular and Nano-YSZ Powders, J. Therm. Spray Technol., 2010, 19, p 2-10

K.H. Kim, M. Watanabe, S. Kuroda, et al., Observation of Microstructures in Thermal Sprayed Coatings and Single Deposited Splats Using Ion Beam Milling, DVS-reports, Vol. 264, 2010, p 1-5

H. Li, S. Costil, H.-L. Liao et al., Effects of Surface Conditions on the Flattening Behavior of Plasma Sprayed Cu Splats, Surf. Coat. Technol., 2006, 200, p 5435-5446

C. Li and J.-L. Li, Evaporated-Gas-Induced Splashing Model for Splat Formation During Plasma Spraying, Surf. Coat. Technol., 2004, 184, p 13-23

M. Fukumoto, E. Nishioka, and T. Matsubara, Flattening and Solidification Behavior of a Metal Droplet on a Flat Substrate Surface Held at Various Temperatures, Surf. Coat. Technol., 1999, 120-121, p 131-137

S. Amada, K. Imagawab, and S. Aokic, Splat Profile of Impinging Droplets on Rough Substrates: Influence of Surface Roughness, Surf. Coat. Technol., 2002, 154, p 27-33

W. Tillmann, B. Hussong, S. Kuhnt, et al., Modeling Properties of HVOF Thermally Sprayed WC-Co Coatings Based on Particle-in-Flight Characteristics, DVS-reports, Vol. 276, 2011, p 732-738

H.F. Voggenreiter, Optimization of the HVOF-Spraying Process for the Manufacturing of Load-Bearing Structures from 316L and Inconel 718, Dissertation, Freiberg, 1996 (in German)

P. Chivavibul, M. Watanabe, S. Kuroda et al., Effects of Carbide Size and Co Content on the Microstructure and Mechanical Properties of HVOF-Sprayed WC-Co Coatings, Surf. Coat. Technol., 2007, 202, p 509-521

R. Dhiman, A.G. McDonald, and S. Chandra, Predicting Splat Morphology in a Thermal Spray Process, Surf. Coat. Technol., 2007, 201, p 7789-7801

S. Sampath and X. Jiang, Splat Formation and Microstructure Development During Plasma Spraying: Deposition Temperature Effects, Mater. Sci. Eng., 2001, A304-306, p 144-150

S. Amada, K. Tomoyasu, and M. Haruyama, Splat Formation of Molten Sn, Cu and Ni Droplets, Surf. Coat. Technol., 1997, 96, p 176-183

W. Liu, L. Lu, and Y. Li, Preferential Spreading of Molten Metal over an Anisotropically Microstructured Surface, EPL, 2012, 97(46003), p 1-6

M. Pasandideh-Fard, V. Pershin, S. Chandra et al., Splat Shapes in a Thermal Spray Coating Process: Simulations and Experiments, J. Therm. Spray Technol., 2002, 11(2), p 206-217

Acknowledgments

The authors gratefully acknowledge the financial support of the DFG (German Science Foundation) within the collaborative research center SFB 823 B1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tillmann, W., Hussong, B., Priggemeier, T. et al. Influence of Parameter Variations on WC-Co Splat Formation in an HVOF Process Using a New Beam-Shutter Device. J Therm Spray Tech 22, 250–262 (2013). https://doi.org/10.1007/s11666-012-9881-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-012-9881-8