Abstract

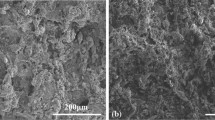

This paper reports the oxidation behavior of TiAl3/Al composite coating deposited by cold spray. The substrate alloy was orthorhombic-Ti-22Al-26Nb (at.%). The oxidation kinetics of the coating was tested at 650, 800, and 950 °C, respectively. The parabolic rate constant for the coating oxidized at 650 °C was k p = 7.2 × 10−2 mg·cm−2·h−1/2 for the tested 1200 h. For the coating oxidized at 800 °C, the oxidation kinetics could be separated into two stages with k p value of 39.8 × 10−2 mg·cm−2·h−1/2 for the initial 910 h and 17.7 × 10−2 mg·cm−2·h−1/2 for the stage thereafter. For the coating oxidized at 950 °C, the oxidation kinetics can be separated into three stages with k p of 136.9 × 10−2 mg·cm−2·h−1/2 in the first 100 h, followed by 26.9 × 10−2 mg·cm−2·h−1/2 from 100 to 310 h, and 11.8 × 10−2 mg·cm−2·h−1/2 from 310 to 1098 h. XRD, SEM, and EPMA were used to study the microstructure of the coating. The results indicated that the oxidation took place throughout the entire coating instead of only at the surface. The aluminum phase in the composite coating was soon oxidized to Al2O3 in all tested cases. The aluminum in TiAl3 phase was depleted gradually and oxidized to Al2O3 along with the degradation of TiAl3 to TiAl2 and TiAl as the temperature increased and time proceeded. AlTi2N was also a typical oxidation product at temperature higher than 800 °C. The experimental results also indicated that the protection of the coating was attributed greatly to the interlayer formed between the coating and the substrate.

Similar content being viewed by others

References

J.C. Willianms, Intermetallics for Structural Applications Potential, Reality and the Road Ahead, Structural Intermetallics 1997, M.V. Nathal, R. Darolia, C.T. Liu, P.L. Martin, D.B. Miracle, R. Wagner, and M. Yamaguchi, Ed., TMS, Warrendale, PA, 1997, p 3-8

F.C. Dary and T.M. Pollock, Effects of High Temperature Air and Vacuum Exposures on the Room Temperature Tensile Behavior of the (O+B2) Titanium Aluminide Ti-22Al-23Nb, Mater. Sci. Eng., 1996, 208, p 182-202

L. Gauer, S. Alperine, P. Steinmetz, and A. Vassel, Influence of Niobium Additions on High-Temperature-Oxidation Behavior of Ti3Al Alloys and Coatings, Oxid. Met., 1994, 42(1-2), p 49-74

C. Leyens, Environmental Effects on Orthorhombic Alloy Ti-22Al-26Nb in Air Between 650 and 1000 °C, Oxid. Met., 1999, 52(5-6), p 475-503

C. Leyens and M. Peters, Titanium and Titanium Alloys, Wiley-VCH, Weinheim, 2003

S.G. Warrier, S. Krishnamurtby, and P.R. Smith, Oxidation Protection of Ti-Aluminide Orthorhombic Alloys: An Engineered Multilayer Approach, Metal. Mater. Trans., 1998, 29(4), p 1279-1288

R. Braun and C. Leyens, Protective Coatings on Orthorhombic Ti2AlNb Alloys, Mater. High Temp., 2005, 22(3-4), p 437-447

Q.M. Wang, K. Zhang, J. Gong, Y.Y. Cui, C. Sun, and L.S. Wen, NiCoCrAlY Coatings with and Without an Al2O3/Al Interlayer on an Orthorhombic Ti2AlNb-Based Alloy: Oxidation and Interdiffusion Behaviors, Acta. Mater., 2007, 55, p 1427-1439

S.C. Kung, High-Temperature Coating for Titanium Aluminides Using the Pack-Cementation Technique, Oxid. Met., 1990, 24(3-4), p 217-228

K. Zhang, C. Sun, and F.H. Wang, Preparation and Protection of Al Diffusion Coatings on Matrix r-TiAl, Acta. Met. Sin., 2006, 42, p 355-360

V. Gauthier, F. Dettenwanger, M. Schütze, V. Shemet, and W.J. Quadakkers, Oxidation-Resistant Aluminide Coatings on r-TiAl, Oxid. Met., 2003, 59, p 233-254

Z.D. Xiang, S.R. Rose, and P.K. Datta, Pack Formatin and Long Term Oxidation Kinetics of TiAl3 Coating on r-TiAl, Mater. Sci. Technol., 2005, 21, p 1111-1118

L. Shen, L.Y. Kong, T.Y. Xiong, H. Du, and T.F. Li, Preparation of TiAl-Al Composite Coating by Cold Spraying, Trans. Nonferrous Met. Soc. China, 2009, 19, p 879-882

L.Y. Kong, J.Z. Qi, B. Lu, X.Y. Cui, H. Du, T.F. Li, and T.Y. Xiong, Oxidation Resistance of TiAl3-Al Composite Coating on Ti-22Al-26Nb Alloy, Surf. Coat. Technol. (submitted)

B. Pieraggi, Calculations of Parabolic Reaction Rate Constants, Oxid. Met., 1987, 24(3/4), p 177-185T

Novoselova, P. Fox, R. Morgan, and W. O’Neill, Experimental Study of Titanium/Aluminium Deposits Produced by Cold Gas Dynamic Spray, Surf. Coat. Technol., 2006, A433, p 139-143

Acknowledgment

The financial support of the National Natural Science Foundation of China (No. 50971127) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kong, L., Lu, B., Cui, X. et al. Oxidation Behavior of TiAl3/Al Composite Coating on Orthorhombic-Ti2AlNb Based Alloy at Different Temperatures. J Therm Spray Tech 19, 650–656 (2010). https://doi.org/10.1007/s11666-010-9473-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-010-9473-4