Abstract

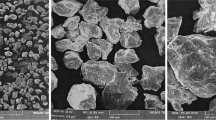

Abradable coatings in compressor and high-pressure stages of gas turbines must provide specific hardness and porosity values to achieve an optimal cut-in of the blade tips. A fractional factorial experimental plan was designed to investigate the influence of the plasma spraying parameters argon flow rate, current, spraying distance and powder feed rate on these properties of magnesia spinel. Based on the results, magnesia spinel coatings with low (~400 HV0.5), medium (~600 HV0.5) and high hardness (~800 HV0.5) could be reliably manufactured. Further incursion rig tests confirmed the dependence of the rub-in behavior and abradability on the coating characteristics and process parameters, respectively. Process monitoring was also applied during plasma spraying of magnesia spinel abradables on batches of turbine components. The recorded particle characteristics and coating properties showed a good reproducibility of the spraying process.

Similar content being viewed by others

References

R.K. Schmid, F. Ghasripoor, M. Dorfman, and X. Wei, An Overview of Compressor Abradables, Thermal Spray: Surface Engineering via Applied Research, C.C. Berndt, Ed., May 8-11, 2000 (Montréal, QC, Canada), ASM International, 2000, p 1087-1093

D. Sporer, S. Wilson, I. Giovannetti, A. Refke, and M. Giannozzi, On the Potential of Metal and Ceramic Based Abradables in Turbine Seal Applications, Proceedings of the Thirty-Sixth Turbomachinery Symposium, Sept 11-13, 2007 (Texas A&M University, College Station, TX), 2007, p 79-86

D. Sporer, M. Dorfman, L. Xie, A. Refke, I. Giovannetti, and M. Giannozzi, Processing and Properties of Advanced Ceramic Abradable Coatings, Thermal Spray 2007: Global Coating Solutions, M.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed., May 14-16, 2007 (Beijing, Japan), ASM International, 2007, p 495-500

R.S. Lima, B.R. Marple, A. Dadouche, W. Dmochowski, and B. Liko, Nanostructured Abradable Coatings for High Temperature Application, Thermal Spray 2006: Building on 100 Years of Success, M.R. Marple, M.M. Hyland, Y.-C. Lau, R.S. Lima, and J. Voyer, Ed., May 15-18, 2006 (Seattle, WA, USA), ASM International, 2006

R. Schmid, “New High Temperature Abradables for Gas Turbines,” Ph.D. Thesis, Swiss Federal Institute of Technology Zurich, 1997

F. Ghasripoor, R. Schmid, and M. Dorfman, Abradable Coatings Increase Gas Turbine Efficiency, Mater. World, 1997, 5(6), p 328-330

R. Vaßen, F. Traeger, and D. Stöver, New Thermal Barrier Coatings Based on Pyrochlore/YSZ Double-Layer Systems, Int. J. Appl. Ceram. Technol., 2004, 1(4), p 351-361

R. Vaßen, A. Stuke, and D. Stöver, Recent Developments in the Field of Thermal Barrier Coatings, J. Therm. Spray Technnol., 2009, 18(2), p 181-186

Shroud Segment for a Turbomachine, U.S. Patent US 2005/0276688 A1

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, 2. ed., Wiley, Chichester, 2008

A. Kulkarni, A. Vaidya, A. Goland, S. Sampath, and H. Herman, Processing Effects on Porosity-Property Correlations in Plasma Sprayed Yttria-Stabilized Zirconia Coatings, Mater. Sci. Eng. A, 2003, A359(1-2), p 100-111

M. Friis and C. Persson, Process Window for Plasma Spray Processes, Thermal Spray 2001: New Surfaces for a New Millennium, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., May 28-30, 2001 (Singapore), ASM International, 2001, p 1313-1319

C. Pierlot, L. Pawlowski, M. Bigan, and P. Chagnon, Design of Experiments in Thermal Spraying: A Review, Surf. Coat. Technol., 2008, 202(18), p 4483-4490

G. Mauer, R. Vaßen, and D. Stöver, Comparison and Applications of DPV-2000 and Accuraspray-g3 Diagnostic Systems, J. Therm. Spray Technol., 2007, 16(3), p 414-424

Advanced Technical Ceramics—Mechanical Properties of Monolithic Ceramics at Room Temperature—Part 4: Vickers, Knoop and Rockwell Superficial Hardness; German Version EN 843-4:2005, DIN Deutsches Institute für Normung e.V., p 1-22

J. Malzbender and R.W. Steinbrech, Determination of the Stress-Dependent Stiffness of Plasma-Sprayed Thermal Barrier Coatings Using Depth-Sensitive Indentation, J. Mater. Res., 2003, 18(8), p 1975-1984

G. Bertrand, P. Bertrand, P. Roy, C. Rio, and R. Mevrel, Low Conductivity Plasma Sprayed Thermal Barrier Coating Using Hollow PSZ Spheres: Correlation Between Thermophysical Properties and Microstructure, Surf. Coat. Technol., 2008, 202(10), p 1994-2001

J. Matějíček, B. Kolman, J. Dubský, K. Neufuss, N. Hopkins, and J. Zwick, Alternative Methods for Determination of Composition and Porosity in Abradable Materials, Mater. Charact., 2006, 57(1), p 17-29

J. Ilavsky, C.C. Berndt, and J. Karthikeyan, Mercury Intrusion Porosimetry of Plasma-Sprayed Ceramic, J. Mater. Sci., 1997, 32(15), p 3925-3932

Acknowledgments

The authors gratefully acknowledge the support of Dr. Jürgen Malzbender (Forschungszentrum Jülich GmbH, IEF-2) who carried out the hardness and Young’s modulus measurements with instrumented microindentation technique. Mr. Mark Kappertz (IEF-1) kindly prepared the cross-sections of the samples and Dr. Doris Sebold (IEF-1) did the SEM work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Steinke, T., Mauer, G., Vaßen, R. et al. Process Design and Monitoring for Plasma Sprayed Abradable Coatings. J Therm Spray Tech 19, 756–764 (2010). https://doi.org/10.1007/s11666-010-9468-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-010-9468-1