Abstract

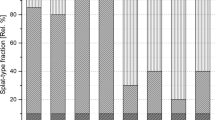

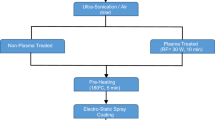

The quality of coatings made using thermal spray processes depends greatly on the degree of adhesion between the substrate and its coating. Yet the bonding mechanisms between a substrate and coating are not well understood. In this study, polyetheretherketone (PEEK) powder was plasma-sprayed to form single splats on aluminum substrates, which had undergone various surface treatments, including boiled (BT), etched (E, ET), and polished (PT), all of which had also been thermally treated to remove water from the substrate surface, with the exception of one etched aluminum substrate. Scanning electron microscopy was used to give an overview of the surface and splat morphology. The splat-substrate interfaces were studied in detail using focused ion beam imaging and transmission electron microscopy, to characterize microstructural features within the splat-substrate interface, including inter/intrasplat pores, pores along the splat-substrate interface, level of contact between the splat and the substrate, etc. The results showed that the splat-substrate interface for the BT and the E substrate surface had poor level of contact, with a high number of small pores (<1 μm) along the splat-substrate interface for the BT splat-substrate interface, and the formation of a near-continuous crevice between the PEEK splat and the aluminum substrate for the E substrate surface. The presence of the fine needle-like network of oxide layer on the BT substrate surface may have restricted the flow of the molten PEEK on the aluminum substrate, and the possible presence of physisorbed and chemisorbed water on the E substrate surface may have reduced the level of contact between the PEEK and the aluminum substrate. In contrast, specimens which had undergone thermal treatment to minimize the presence of water on the substrate surface, such as the ET and PT substrate surface, exhibited high level of contact at the splat-substrate interface. The number of pores for the ET and the PT splat-substrate interfaces were substantially lower than of the BT and E splat-substrate interface.

Similar content being viewed by others

References

G. Zhang, W.Y. Li, M. Cherigui, C. Zhang, H. Liao, J.M. Bordes, and C. Coddet, Structures and Tribological Performances of PEEK (Poly-Ether-Ether-Ketone)-Based Coatings Designed for Tribological Application, Prog. Org. Coat., 2007, 60, p 39-44

H. Herman, Plasma-Sprayed Coatings, Sci. Am., 1988, 259(3), p 112-117

J.M. Guilemany, J. Nutting, V.V. Sobolev, Z. Dong, J.M. de Paco, J.A. Calero, and J. Fernandez, Interface Structures of High Velocity Oxy-Fuel Sprayed WC-Co Coating on a Copper Substrate, Mater. Sci. Eng. A, 1997, 232, p 119-128

M. Mellali, A. Grimaud, A.C. Leger, P. Fauchais, and J. Lu, Alumina Grit Blasting Parameters for Surface Preparation in the Plasma Spraying Operation, J. Therm. Spray Technol., 1997, 6(2), p 217-227

B.P. Withy, M.M. Hyland, and B.J. James, The Effect of Surface Chemistry and Morphology on the Properties of HVAF PEEK Single Splats, J. Therm. Spray Technol., 2008, 17(5-6), p 631-636

S.J. Hitchcock, N.T. Carroll, and M.G. Nicholas, Some Effects of Substrate Roughness on Wettability, J. Mater. Sci., 1981, 16, p 714-723

L.A. Utracki, Commercial Polymer Blends, Chapman & Hall, London, UK, 1998, p 440

J.J. Licari, Coating Materials for Electronic Applications: Polymers, Processes, Reliability, Testing, Chap. 2, Noyes Publications and William Andrew Publishing, New York, 2003, p 187-188

A.T.T. Tran, M.M. Hyland, T. Qiu, B. Withy, and B.J. James, Effects of Surface Chemistry on Splat Formation During Plasma Spraying, J. Thermal Spray Technol., 2008, 17(5-6), p 637-645

B. Withy, M. Hyland, and B. James, Pretreatment Effects on the Surface Chemistry and Morphology of Aluminum, Int. J. Modern Phys. B, 2006, 20(25-27), p 3611-3616

J. Mayer, L.A. Giannuzzi, T. Kamino, and J. Michael, TEM Sample Preparation and FIB-Induced Damage, Mater. Res. Bull., 2007, 32, p 400-407

N.Z. Mehdizadeh, S. Chandra, and J. Mostaghimi, Adhesion of Tin Droplets Impinging on a Stainless Steel Plate: Effect of Substrate Temperature and Roughness, Sci. Technol. Adv. Mater., 2003, 4, p 173-181

S.D. Siegmann and C.A. Brown, Investigation of Substrate Roughness in Thermal Spraying by a Scale-Sensitive 3-D Fractal Analysis, Thermal Spray: Meeting the Challenges of the 21st Century, C. Coddet, Ed., May 25-29, 1998 (Nice, France), ASM International, 1998, p 831-836

Y.Y. Wang, C.J. Li, and A. Ohmori, Influence of Substrate Roughness on the Bonding Mechanisms of High Velocity Oxy-Fuel Sprayed Coatings, Thin Solid Films, 2005, 485, p 141-147

T. Palathai, J. Tharajak, and N. Sombatsompop, Hardness, Adhesion Index and Microstructure of PEEK Coating on Al or Fe Substrate by LVOF Flame spray, Mater. Sci. Eng. A, 2008, 485, p 66-73

G. Zhang, H. Liao, M. Cherigui, J.P. Davim, and C. Coddet, Effect of Crystalline Structure on the Hardness and Interfacial Adherence of Flame Sprayed Poly(Ether-Ether-Ketone) Coatings, Eur. Polym. J., 2007, 43, p 1077-1082

N.A. Thorne, P. Thuery, A. Frichet, P. Gimenez, and A. Sartre, Hydration of Oxide Films on Aluminum and its Relation to Polymer Adhesion, Surf. Inter. Anal., 1990, 16, p 236-240

Acknowledgments

The authors thank the Australian Research Council for financial support. J. Wu would like to thank all the authors for providing all the specimens, feedback and resources.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2009 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Expanding Thermal Spray Performance to New Markets and Applications: Proceedings of the 2009 International Thermal Spray Conference, Las Vegas, Nevada, USA, May 4-7, 2009, Basil R. Marple, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and Ghislain Montavon, Ed., ASM International, Materials Park, OH, 2009.

Rights and permissions

About this article

Cite this article

Wu, J., Munroe, P.R., Withy, B. et al. Study of the Splat-Substrate Interface for a PEEK Coating Plasma-Sprayed onto Aluminum Substrates. J Therm Spray Tech 19, 42–48 (2010). https://doi.org/10.1007/s11666-009-9430-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-009-9430-2