Abstract

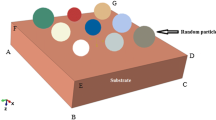

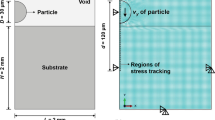

Effective physical and mechanical properties of thermal barrier coatings are strongly dependent on the coating microstructure. The main objective of this study is the coating porosity prediction during the coating formation by simulation. For this purpose, two simulation approaches are presented. The first model takes into account physical impact, deformation, and overlying of powder particles on the solid substrate. Therefore, computational fluid dynamics and the volume of fluid method for this model were used. In the second approach, a faster and therefore more efficient model was developed, hence it was strongly simplified to simulate the formation of coatings and their microstructure. The splat formation was handled by calculating the flattening degree as a function of the Reynolds number. The disc-shaped particles were discretized by cuboids. The neighboring cuboids are moveable against each other at their contact areas. The displacement of those depends on material properties and the Reynolds number as well. Both approaches for predicting the microstructure were mutually compared.

Similar content being viewed by others

References

P. Fauchais, Understanding Plasma Spraying, J. Phys. D: Appl. Phys., 2004, 37, p R86-R108

P. Fauchais, M. Fukumoto, A. Vardelle, M. Vardelle Knowledge Concerning Splat Formation: An invited review, J. Thermal Spray Technolo. 13(3): 337-360 2004

R. Nickel, “Die beschichtungsprozessabhängige Materialmodellierung von EB-PVD- und APS-Wärmedämmschichten,” PhD Thesis, Surface Engineering Institute, RWTH Aachen, 2007, p 3-14

S. Chandra and P. Fauchais, Formation of Solid Splats During Thermal Spray Deposition, J. Therm. Spray Technol., 2009

S. Ahmaniemi, J. Tuominen, M. Vippola, P. Vuoristo,T. Mäntylä, F. Cernuschi, C. Gualco, A. Bonadei, R. Di Maggio, and S. Ahmaniemi, Characterization of Modified Thick Thermal Barrier Coatings, J. Therm. Spray Technol., 2004, 13(3), p 361-369

A. Zagorski, F. Szuecs, V. Balaschenko, S. Siegmann, N. Margandant, and A. Ivanov, Experimental Study of substrate thermal conditions at APS and HVOF, Proceeding of the 2003 International Thermal Spray Conference, Orlando, Florida, USA, 2003, p 1255-1260

H. R. Salimijazi, L. Pershin, T. W. Coyle, J. Mostaghimi, S. Chandra, Y. C. Lau, L. Rosenzweig, E. Moran, Effect of Droplet Characteristics and Substrate Surface Topography on the Final Morphology of Plasma-Sprayed Zirconia Single Splats, J. Thermal Spray Technolo., 16 (2), p 291-299 2007

H. B. Parizi, L. Rosenzweig, J. Mostaghimi, S. Chandra, T. Coyle, L. Pershin, A. McDonald, C. Moreau Numerical Simulation of Droplet Impact on Patterned Surfaces, J. Thermal Spray Technolo. 16 (5): 713-721 2007

T. Steinke and M. Bäcker, Monte Carlo Simulation of Thermal Sprayed Coatings, Proceeding of the 2006 International Thermal Spray Conference, Seattle, Washington, USA, 2006

M. Vardelle, A. Vardelle, A.C. Leger, P. Fauchais, D. Gobin, Influence of Particle Parameters at Impact on Splat Formation and Solidification in Plasma Spraying Processes, J. Therm. Spray Technol. 4: 50-58, 1994

M.R. Barkhudarov and C.W. Hirt, Casting Simulation: Mold Filling and Solidification-Benchmark Calculations Using FLOW-3D, Modeling of Casting, Welding, and Advanced Solidification Processes VII, 1993, p 935-946

M. Pasandideh-Fard, S. Chandra, J. Mostaghimi A three-dimensional model of droplet impact and solidification, Int. J. Heat Mass Transfer 45: 2229-2242 2002

J. Madejski, Solidification of Droplets on a Cold Surface, Int. J. Heat Mass Trans. 19(9): 1009-1013, 1976

C. Mundo, M. Sommerfeld, C. Tropea, Droplet-Wall Collisions: Experimental Studies of the Deformation and Breakup Process, International Journal of Multiphase Flow 21(2):151-173, 1995

C. Mundo, U. Lackermeier, M. Sommerfeld, and C. Tropea, Numerical and Experimental Studies of the Splashing and Deposition of Spray Droplets on Surfaces, 11th ILASS Europe, Nürnberg, Germany, 1995

C. Escure, M. Vardelle, P. Fauchais Experimental and Theoretical Study of the Impact of Alumina Droplets on Cold and Hot Substrates, Plasma Chem. Plasma Process. 23(2): 185-221 2003

M. Fukumoto, E. Nishioka, T. Nishiyama, New Criterion for Splashing in Flattening of Thermal Sprayed Particles onto Flat Substrate Surface, Surf. Coat. Technol. 161(2-3): 103-110, 2002

H. Jones Cooling, Freezing and Substrate Impact of Droplets Formed by Rotary Atomization, Journal of Physics D: Applied Physics 4(11):1657-1660, 1971

H. Guo, S. Kuroda, H. Murakami Microstructures and Properties of Plasma-Sprayed Segmented Thermal Barrier Coatings, J. Am. Ceram. Soc. 89(4): 1432-1439, 2006

Acknowledgment

The authors gratefully acknowledge the financial support of the German Research Foundation (DFG) within the Collaborated Research Centre Transfer Project TFB 63 “Applied modeling tools.”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bobzin, K., Bagcivan, N., Parkot, D. et al. Modeling and Simulation of Microstructure Formation for Porosity Prediction in Thermal Barrier Coatings Under Air Plasma Spraying Condition. J Therm Spray Tech 18, 975–980 (2009). https://doi.org/10.1007/s11666-009-9340-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-009-9340-3