Abstract

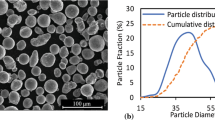

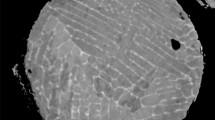

The degree of bonding between particles within cold-sprayed deposits is of great importance as it affects their mechanical and physical properties. This article describes a method for characterizing the bonding between aluminum and copper particles following deposition by cold spraying. Aluminum and copper powders were blended in the ratio 1:1 by volume, deposited onto a copper substrate and subsequently heat treated at 400 °C for 15 min. An intermetallic layer formed along some regions of the aluminum-copper boundaries, believed to be where true metal to metal contact had occurred. In other regions, metal to metal contact was inhibited by the presence of oxide films. Image analysis was employed to measure the fraction of the aluminum-copper interface covered with intermetallic phases and to estimate intermetallic thicknesses. By increasing the primary gas pressure in the cold-spray process, an increase in the degree of inter-particle bond formation was observed.

Similar content being viewed by others

References

R.C. Dykhuizen, M.F. Smith, Gas Dynamic Principles of Cold Spray. J. Therm. Spray Technol., 1998, 7, 205–212

T. Schmidt, F. Gartner, H. Assadi, H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition. Acta Mater., 2006, 54, 729–742

S.V. Klinkov, V.F. Kosarev, M. Rein, Cold Spray Deposition: Significance of Particle Impact Phenomena. Aerosp. Sci. Technol., 2005, 9, 582–591

H. Assadi, F. Gartner, T. Stoltenhoff, H. Kreye, Bonding Mechanism in Cold Gas Spraying. Acta Mater., 2003, 51, 4379–4394

T.H. Van Steenkiste, J.R. Smith, R.E. Teets, Aluminum Coatings Via Kinetic Spray with Relatively Large Powder Particles. Surf. Coat. Technol., 2002, 154, 237–252

M. Grujicic, C.L. Zhao, W.S. DeRosset, D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process. Mater. Design, 2004, 25, 681–688

R.C. Dykhuizen, M.F. Smith, D.L. Gilmore, R.A. Neiser, X. Jiang, S. Sampath, Impact of High Velocity Cold Spray Particles. J. Therm. Spray Technol., 1999, 8, 559–564

T. Stoltenhoff, C. Borchers, F. Gartner, H. Kreye, Microstructures and Key Properties of Cold-Sprayed and Thermally Sprayed Copper Coatings. Surf. Coat. Technol., 2006, 200, 4947–4960

V.K. Champagne, D. Helfritch, P. Leyman, S.G. Ahl, B. Klotz, Interface Material Mixing Formed by the Deposition of Copper on Aluminum by Means of the Cold Spray Process. J. Therm. Spray Technol., 2005, 14, 330–334

C. Borchers, F. Gartner, T. Stoltenhoff, H. Kreye, Microstructural Bonding Features of Cold Sprayed Face Centered Cubic Metals. J. Appl. Phys., 2004, 96, 4288–4292

J.W. Wu, H.Y. Fang, S. Yoon, H. Kim, C. Lee, The Rebound Phenomenon in Kinetic Spraying Deposition. Scripta Mater., 2006, 54, 665–669

T. Stoltenhoff, H. Kreye, H.J. Richter, An Analysis of the Cold Spray Process and its Coatings. J. Therm. Spray Technol., 2002, 11, 542–550

A. Bolesta, V.M. Fomin, M.R. Sharafutdinov, B.P. Tolochko, Investigation of Interface Boundary Occurring During Cold Gas-Dynamic Spraying of Metallic Particles. Nucl. Instrum. Meth. Phys. Res. Sec. A-Accelerat. Spectrom. Detect. Assoc. Equip., 2001, 470, 249–252

R.C. McCune, W.T. Donlon, O.O. Popoola, E.L. Cartwright, Characterization of Copper Layers Produced by Cold Gas-Dynamic Spraying. J. Therm. Spray Technol., 2000, 9, 73–82

R. Morgan, P. Fox, J. Pattison, C. Sutcliffe, W. O’Neill, Analysis of Cold Gas Dynamically Sprayed Aluminium Deposits. Mater. Lett., 2004, 58, 1317–1320

K. Balani, A. Agarwal, S. Seal, J. Karthikeyan, Transmission Electron Microscopy of Cold Sprayed 1100 Aluminum Coating. Scripta Mater., 2005, 53, 845–850

I. Manna, J.D. Majumdar, Enhanced Kinetics of Diffusion Coating of Aluminum on Copper by Boundary Diffusion. J. Mater. Sci. Lett., 1993, 12, 920–922

Y. Funamizu, K. Watanabe, Interdiffusion in Al-Cu System. Trans. Jpn. Inst. Metals, 1971, 12, 147–152

F.A. Calvo, A. Urena, J.M.G. Desalazar, F. Molleda, Special Features of the Formation of the Diffusion Bonded Joints between Copper and Aluminum. J. Mater. Sci., 1988, 23, 2273–2280

E. Calla, D.G. McCartney, and P.H. Shipway. Effect of heat treatment on the structure and properties of cold sprayed copper. In Thermal Spray 2005: Advances in Technology and Application. DVS, Basel, Switzerland, 2005

Acknowledgments

T.S. Price acknowledges financial support from the Nottingham Innovative Manufacturing Research Centre (NIMRC) and the EPSRC in the form of a Ph.D. studentship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Price, T.S., Shipway, P.H., McCartney, D.G. et al. A Method for Characterizing the Degree of Inter-particle Bond Formation in Cold Sprayed Coatings. J Therm Spray Tech 16, 566–570 (2007). https://doi.org/10.1007/s11666-007-9070-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-007-9070-3