Abstract

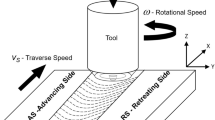

The mechanical and corrosion characteristics of the friction stir welds (FSW) are defined by the heat generated throughout the process. The backing plate material is crucial for effective temperature control during the FSW process. The detailed examination comprehends how the backing plate material influences the mechanical and corrosion characteristics of AA6061 FSW joints. In this investigation, FSW process variables such as backing plate, the rotation speed of the tool, and traverse speed were varied to obtain a suitable combination of parameters to achieve high corrosion resistance of joints along with satisfactory mechanical properties. An exfoliation corrosion test is carried out to determine the welds' corrosion resistance. An electrical conductivity test was performed to identify the relationship between hardness and electrical conductivity. The results demonstrated that the lowest corrosion rate, 0.8174 mm per year (mm/year), was achieved by a weld produced using an aluminum backing plate at 1200 rpm and 60 mm/min. The weld with the composite backing plate at 1200 rpm, 30 mm/min exhibits the highest corrosion rate of 1.559 mm/year. The maximum ultimate tensile strength (UTS) is found in joints with an aluminum backing plate. Visual observations indicate that post-weld machining improves the corrosion resistance of FSW samples.

Similar content being viewed by others

References

J. He, Z. Ling, and H. Li, Effect of Tool Rotational Speed on residual Stress, Microstructure, and Tensile Properties of Friction Stir Welded 6061–T6 Aluminium Alloy Thick Plate, Int. J. Adv. Manuf. Technol., 2016, 84, p 1953–1961. https://doi.org/10.1007/s00170-015-7859-7

A.K. Kadian and P. Biswas, Effect of Tool Pin Profile on the Material Flow Characteristics of AA6061, J. Manuf. Process., 2017, 26, p 382–392. https://doi.org/10.1016/j.jmapro.2017.03.005

F.C. Liu and Z.Y. Ma, Influence of Tool Dimension and Welding Parameters on Microstructure and Mechanical Properties of Friction Stir Welded 6061–T651 Aluminium Alloy, Metall. Mater. Trans., 2008, 39A, p 2378–2388. https://doi.org/10.1007/s11661-008-9586-2

S. Rajakumar, C. Murlidharan, and V. Balsubramanian, Establishing Empirical Relationship to Predict Grain Size and Tensile Strength of Friction Stir Welded AA6061-T6 Aluminium Alloy Joints, Trans. Nonferrous Met. Soc. China., 2010, 20(10), p 1863–1872. https://doi.org/10.1016/S1003-6326(09)60387-3

V. Fahimpour, S.K. Sadrnezhaad, and F. Kaimzadeh, Corrosion Behaviour of Aluminium 6061 Alloy Joined by Friction Stir Welding and Gas Tungsten Arc Welding Methods, Mater. Des., 2011, 39, p 329–333. https://doi.org/10.1016/j.matdes.2012.02.043

A. Heidarzadeh, H. Khodaverdizadeh, A. Mahmoudi, and E. Nazari, Tensile Behaviour of Friction Stir Welded AA 6061–T4 Aluminium Alloy Joints, Mater. Des., 2012, 37, p 166–173. https://doi.org/10.1016/j.matdes.2011.12.022

S. Ugender and A. Kumar, A Somi Reddy, Influence of Friction Stir Welding Parameters on Mechanical Properties of 6061–T6 Aluminium Alloy, Res. Rev.: J. Eng. Technol., 2014, 3, p 9–13.

G. Elatharasan and V.S. Senthil Kumar, An Experimental Analysis and Optimization Of Process Parameters on Friction Stir Welding of AA 6061–T6 Aluminium Alloy Using RSM, Procedia Eng., 2013, 64, p 1227–1234. https://doi.org/10.1016/j.proeng.2013.09.202

D. Raghvendra and S. Ugender, Optimizing the Process Parameters of Friction Stir Welded AA 6061–T6 Alloy Using Taguchi Orthogonal Technique, Int. J. Curr. Eng. Sci. Res., 2014, 1, p 48–55.

K. Ashwani, S.S. Gautam, and K. Alok, Heat Input and Joint Efficiency of Three Welding Processes TIG, MIG and FSW using AA6061, Int. J. Mech. Eng. Robot. Res., 2014, 1, p 89–94.

S.A. Kh, F.A. Hashim, and A.O. Al-Rouba, Mechanical Properties and Microstructure of 6061–T651 Aluminium Alloy Welded by Friction Stir Welding, Int. J. Mech. Mater. Eng., 2012, 12, p 723–734.

M. Ilangovan, S. Rajendra Boopathy and V. Balasubramanian, Effect of Tool Pin Profile on Microstructure and Tensile Properties of Friction Stir Welded Dissimilar AA 6061–AA 5086 Aluminium Alloy Joints, Defence Technology, 2015, 11(2), p 174–184. https://doi.org/10.1016/j.dt.2015.01.004

R. Palanivel, P. Koshy Mathews and N. Murugan, Development of Mathematical Model to Predict the Mechanical Properties of Friction Stir Welded AA6351 Aluminum Alloy, J. Eng. Sci. Technol. Rev., 2011, 4(1), p 25–31. https://doi.org/10.25103/jestr.041.03

A.H. Lotfi and S. Nourouzi, Predictions of the Optimized Friction Stir Welding Process Parameters For Joining AA 7075–T6 Aluminium Alloy Using Preheating System, Int. J. Adv. Manuf. Technol., 2014, 73, p 1717–1737. https://doi.org/10.1007/s00170-014-5963-8

M.K. Kulekci, E. Kaluc, A. Sik, and O. Basturk, Experimental Comparison of Mig and Friction Stir Welding Processes for AA6061-T6 Aluminium alloy, Arab. J. Sci. Eng., 2010, 35, p 321–330.

L. Zhou, G.H. Li, C.L. Liu, J. Wang, Y.X. Huang, J.C. Feng, and F.X. Meng, Effects of Rotation Speed on Microstructure and Mechanical Properties of Self Reacting Friction Stir Welded Al-Mg-Si Alloy, Int. J. Adv. Manuf. Technol., 2017, 9, p 3509–3516. https://doi.org/10.1007/s00170-016-9318-5

P. Upadhyay and A.P. Reynolds, Effect of Backing Plate Thermal Property on Friction Stir Welding of 25 mm Thick AA 6061, Metall. Mater. Trans. A, 2014, 45A, p 2091–2100. https://doi.org/10.1007/s11661-013-2121-0

B.S. Kulkarni, S.B. Pankade, S.R. Andhale, and C.L. Gogte, Effect of Backing Plate Material Diffusivity on Microstructure, Mechanical Properties of Friction Stir Welded Joints: A Review, Procedia Manufact., 2018, 20, p 59–64. https://doi.org/10.1016/j.promfg.2018.02.008

A. Mishra, A.K. Sharma, H. Kapoor, J. Singh, and K. Kumar, Investigation on the Tensile Strength of the Friction Stir Welded similar joint of Al/Al alloy using high thermal diffusivity backing plate material., Inter. J. Therm. Technol., 2018 https://doi.org/10.14741/ijtt/v.8.2.1

P. Upadhyay and A.P. Reynolds, Thermal Management in Friction Stir Welding of Precipitation Hardened Aluminium Alloys, JOM, 2015, 67, p 1022–1031. https://doi.org/10.1007/s11837-015-1381-0

P. Upadhay and A.P. Reynolds, Effect of Forge Axis Force and Backing Plate Boundary Condition on FSW of AA6056, Mater. Sci. Eng. A, 2012, 558, p 394–402. https://doi.org/10.1016/j.msea.2012.08.018

M. Imam, V. Racherla and K. Biswas, Effect of Backing Plate Material in Friction Stir Butt and Lap Welding of 6063–T4 Aluminium Alloy, J. Adv. Manuf. Technol., 2015, 77, p 2181–2195. https://doi.org/10.1007/s00170-014-6617-6

Z. Zhang, J. Wenya Li, Y.J. Shen, J Li. Chao, and Yu.-E. Ma, Effect of Backplate Diffusivity on Microstructure and Mechanical Properties of Friction Stir Welded Joints, Mater. Des., 2013, 50, p 551–557. https://doi.org/10.1016/j.matdes.2013.03.034

SeongHwan Park, YoungHwan Joo, and M. Kang, Effect of Backing Plate Materials in Micro Friction Stir Butt Welding of Dissimilar AA6061-T6 and AA5052-H32 Aluminium Alloy, Metals, 2020, 10(7), p 933. https://doi.org/10.3390/met10070933

S. Raja, R. Manikumar, R. Benruben, and S. Raghunathan, Effect of Backing Plate on Strength and Microstructural Characteristics of Friction Stir Welded AA2014-T6 Aluminium Alloy Joints, Mater. Today: Proceed., 2020, 45(2), p 895–899. https://doi.org/10.1016/j.matpr.2020.02.938

M. Paider, D. Bokov, S. Mehrez, M. Nasution, O. Ojo, and A. Zain, The Influence of the Backing Plate Materials on Microstructure and Mechanical Properties of Friction Stir Spot Extrusion Brazing of AA 2024–T3 Aluminium Alloy and Brass Sheet, J. Manuf. Process., 2022, 4, p 28–39. https://doi.org/10.1016/j.jmapro.2021.12.002

F. Liu, Fu. Li, and H. Chen, High Speed Friction Stir Welding of Ultra Thin AA6061-T6 Sheets Using Different Backing Plates, J. Manuf. Process., 2018, 33, p 219–227. https://doi.org/10.1016/j.jmapro.2018.05.020

T. Srinivasa Rao, G. Madhusudhan Reddy, G. Srinivasa Rao, and S.R. Koteswara Rao, Studies on Salt Fog Corrosion Behaviour of Friction Stir Welded AA7075-T651 Aluminium Alloy, Inter. J. Mater. Res., 2014, 105(4), p 375–385. https://doi.org/10.3139/146.111033

F. Gharavi, K.A. Matori, R. Yunus and N.K. Othman, Corrosion Behaviour of Friction Stir Welded Lap Joints of AA6061 T-6 Aluminium Alloy, Mater. Res., 2015, 17(3), p 672–681. https://doi.org/10.1590/S1516-14392014005000053

H. Qin, H. Zhang, D.-T. Sun, and Q.-Y. Zhuang, Corrosion Behavior of the Friction-Stir-Welded Joints of 2A14-T6 Aluminum Alloy, Inter. J. Miner., Metall. Mater., 2015, 22(6), p 627–638. https://doi.org/10.1007/s12613-015-1116-9

K.S. Hassan, M. Abbass, and M.T. Mohammed, Effect of Surface Finishing on Microstructure and Corrosion behaviour of Friction Stir Welded Joints for Dissimilar Aluminium Alloys AA2024 with AA6061-T6, IOP Conference Series: Mater. Sci. Eng., 2021, 1105(1), p 012047. https://doi.org/10.1088/1757-899X/1105/1/012047

A. Laska, M. Szkodo, D. Koszelow, and P. Cavaliere, Effects of Processing Parameters on Strength and Corrosion Resistance of Friction Stir Welded AA6082, Metals, 2022, 12(2), p 192. https://doi.org/10.3390/met12020192

M. Raturi and A. Bhattacharya, Mechanical Strength, and Corrosion Behavior of Dissimilar Friction Stir Welded AA7075-AA2014 Joints, Mater. Chem. Phys., 2021, 262, p 124338. https://doi.org/10.1016/j.matchemphys.2021.124338

V. Haribalaji, G. Venkatesan, M. Asif, M. Pandian, R. Subbiah, and S. Boopathi, Investigation on Corrosion and Tensile Characteristics: Friction Stir Welding of AA7075 and AA2014, Mater. Today: Proceed., 2022, 66, p 743. https://doi.org/10.1016/j.matpr.2022.04.037

Y. Xie, X. Meng, F. Wang, Y. Jiang, X. Ma, L. Wan, and Y. Huang, Insight on Corrosion Behaviour of Friction Stir Welded AA 2219/AA 2195 Joints in Astronautical Engineering, Corros. Sci., 2021 https://doi.org/10.1016/j.corsci.2021.109800

C. Rathinasuriyan, V.S. Senthil Kumar, and A.G. Shanbhag, Radiography and Corrosion Analysis of Sub-merged Friction Stir Welding of AA6061-T6 alloy, Procedia Eng., 2014, 97, p 810–818. https://doi.org/10.1016/j.proeng.2014.12.355

T.G. Santos, P. Vilaca, and R.M. Miranda, Electrical Conductivity Field Analysis for Evaluation of FSW Joints in AA6013 and AA7075 Alloys, J. Mater. Process. Technol., 2011, 211, p 174–180. https://doi.org/10.1016/j.jmatprotec.2010.08.030

H. Huang, M. Huang, W. Zhang, S. Pospisil, and Wu. Tao, Experimental Investigation on Rehabilitation of Corroded RC Columns with BSP and HPFL under Combined Loadings, J. Struct. Eng., 2020 https://doi.org/10.1061/(ASCE)ST.1943-541X.0002725

Z. Guo, X. Tian, Z. Wu, J. Yang, and Q. Wang, Heat Transfer of Granular Flow Around Aligned Tube Bank in Moving bed: Experimental Study and Theoretical Prediction by Thermal Resistance Model, Energy Convers. Manag, 2022, 257, p 115435. https://doi.org/10.1016/j.enconman.2022.115435

J. Xie, J. Zhang, Z. Zhang, Q. Yang, Kai Guan, Ru. Yuying He, H. Z. Wang, X. Qiu, and Wu. Ruizhi, New Insights on the Different Corrosion Mechanisms of Mg Alloys with Solute-Enriched Stacking Faults or Long Period Stacking Ordered Phase, Corros. Sci., 2022, 198, p 110163. https://doi.org/10.1016/j.corsci.2022.110163

E. Hoyos and M. C. Serna, Basic Tool Design Guidelines for Friction Stir Welding of Aluminum Alloys, Metals, 2021, 11(12), p 2042. https://doi.org/10.3390/met11122042

D. McNaughtan, M. Worsfold, and M.J. Robinson, Corrosion Product Force Measurement in the Study of Exfoliation and Stress Corrosion Cracking in High Strength Aluminium Alloys, Corros. Sci., 2003, 45(10), p 2377–2389. https://doi.org/10.1016/S0010-938X(03)00050-7

J.D. Damborenea and A. Conde, Comparison of Accelerated and Atmospheric Exposure Tests for Corrosion’of Aluminium Alloys, Br. Corros. J., 1995, 30(4), p 292–296.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kulkarni, B., Pankade, S., Tayde, S. et al. Corrosion and Mechanical Aspects of Friction Stir Welded AA6061 Joints: Effects of Different Backing Plates. J. of Materi Eng and Perform 32, 10817–10833 (2023). https://doi.org/10.1007/s11665-023-07900-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07900-x