Abstract

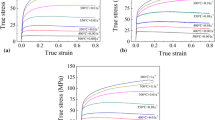

The grain size of materials is significantly reduced by dynamic recrystallization (DRX), which improves the properties and performance of the materials, and it helps to extend the applications further. DRX behavior of the composite materials is greatly affected by the addition of reinforcement to the matrix due to the heterogeneous temperature of the composite. Therefore, the present investigation aims to study the DRX behavior of hot upset sintered Al-B4C composite with various percentages of B4C content (2, 4 and 6 wt.% of B4C) with 90% of initial relative density. Hot upset tests were performed for various temperatures (300-500 °C) and strain rates (0.1-0.3 s−1). The DRX grain size was significantly altered not only with deformation conditions but also with the addition of reinforcement in the matrix. The fracture surface of the sintered composite was analyzed for various compositions. Ductile fracture is observed in the 2 and 4 wt.%B4C content, and ductile and brittle fractures were observed in the 6 wt.%B4C composites. DRX models were established between grain size and deformation conditions for various compositions to predict the grain size, and the developed models were validated. The measured and calculated DRX grain size absolute error and mean absolute error were not exceeding 8.9 and 7.7%, respectively.

Similar content being viewed by others

References

X.J. Wang, X.S. Hu, K.B. Nie, K.K. Deng, K. Wu, and M.Y. Zheng, Dynamic Recrystallization Behavior of Particle Reinforced Mg Matrix Composites Fabricated by Stir Casting, J. Mater. Sci. Eng. A, 2012, 545, p 38–43.

G.E. Kodzhaspirov and M.I. Terentyev, Modeling the Dynamically Recrystallized Grain Size Evolution of a Superalloy, Mater. Phys. Mech., 2012, 13, p 70–76.

M. Shaban and B. Eghbali, Characterization of Austenite Dynamic Recrystallization Under Different Z Parameters in a Microalloyed Steel, J. Mater. Sci. Technol., 2011, 7(4), p 359–363.

Y.C. Lin, S.C. Luo, L.X. Yin, and J. Huang, Microstructural Evolution and High temperature Flow Behaviors of a Homogenized Sr-Modified Al-Si-Mg Alloy, J. Alloys. Compd., 2018, 739, p 590–599.

Y.C. Lin, W.Y. Dong, M. Zhou, D.X. Wen, and D.D. Chen, A Unified Constitutive Model Based on Dislocation Density for an Al-Zn-Mg-Cu Alloy at Time-Variant Hot Deformation Conditions, J. Mater. Sci. Eng. A, 2018, 718, p 165–172.

R. Seetharam, S.K. Subbu, and M.J. Davidson, Analysis of Grain Size Evolution of Sintered Al-4wt.%B4C Preforms Subjected to Hot Compression, Met. Microstruct. Anal., 2018, 7, p 176–183.

Y.L. Liu, N. Hansen, and D.J. Jensen, Effect of Dispersion Parameters and Cold Deformation on Recrystallisation of AI-SiC Composites, Mater. Sci. Technol., 1991, 7, p 270–275.

Y.C. Lin, M.S. Chen, and J. Zhong, Microstructural Evolution in 42CrMo Steel During Compression at Elevated Temperatures, Mater. Lett., 2008, 62, p 2132–2135.

K.R. Ramkumar, S. Ilangovan, S. Sivasankaran, and Abdulaziz S. Alaboodi, Experimental Investigation on Synthesis and Structural Characterization of Cu-Zn- x wt.%Al2O3 (x=0, 3, 6, 9 & 12%) Nanocomposites Powders Through Mechanical Alloying, J. Alloys Compd., 2016, 68, p 518–526.

K.R. Ramkumar, S. Sivasankaran, and A.S. Alaboodi, Effect of Alumina Content on Microstructures, Mechanical, Wear and Machining Behavior of Cu-10Zn Nanocomposite Prepared by Mechanical Alloying and Hot-Pressing, J. Alloys. Compounds, 2017, 709, p 129–141.

K.R. Ramkumar, S. Sivasankaran, and A.S. Alaboodi, Strengthening Mechanisms on (Cu–10Zn)100–x–x wt% Al2O3 (x = 0, 3, 6, 9 and 12) Nanocomposites Prepared by Mechanical Alloying and Vacuum Hot Pressing: Influence of Reinforcement, Trans. Indian Inst. Met., 2017, 70, p 791–800.

M. Ferry and P.R. Munroe, Recrystallization Kinetics and Final Grain Size in a Cold Rolled Particulate Reinforced Al-Based MMC, Compos. Part. A, 2004, 35, p 1017–1025.

K.K. Deng, K. Wu, X.J. Wang, Y.W. Wu, X.S. Hu, M.Y. Zheng, W.M. Gan, and H.G. Brokmeier, Mater. Microstructure Evolution and Mechanical Properties of a Particulate Reinforced Magnesium Matrix Composites Forged at Elevated Temperatures, Sci. Eng. A, 2010, 527, p 1630–1635.

A. El-Sabbagha, M. Solimanb, M. Tahaa, and H. Palkowski, Hot Rolling Behaviour of Stir-Cast Al6061 and Al6082 Alloy–SiC Fine Particulates Reinforced Composites, J. Mater. Process. Technol., 2012, 212, p 497–508.

A. Patel, S. Das, and B.K. Prasad, Hot Deformation Behaviour of AA2014–10 wt.% SiC Composite, Trans. Indian. Inst. Met., 2014, 67(4), p 521–530.

X. Xia, P. Sakaris, and H. Mcqueen, Hot Deformation, Dynamic Recovery, and Recrystallisation Behaviour of Aluminium 6061-SiCp Composite, Mater. Sci. Technol., 1994, 10(6), p 487–496.

M. Ferry and P.R. Munroe, Microstructure and Kinetics of Recrystallisation of Hot Deformed Al-Al2O3 Particulate Reinforced Metal Matrix Composite, Mater. Sci. Technol., 1995, 11(8), p 734–740.

X. Xia and H.J. McQueen, Deformation Behaviour and Bicrostructure of a 20% Al2O3 Reinforced 6061 Al Composite, Appl. Composite. Mater., 1997, 4(6), p 333–347.

R.M. Mohanty and K. Balasubramanian, Boron Rich Boron Carbide: An Emerging High-Performance Material, Key. Eng. Mater., 2009, 395, p 125–142.

J. Abenojar, F. Velasco, and M.A. Martinez, Optimization of Processing Parameters for the Al+10% B4C System Obtained by Mechanical Alloying, J. Mater. Process. Technol., 2007, 184, p 441–446.

T. Thevenot, Boron Carbide—A Comprehensive Review, J. Eur. Ceram. Soc., 1990, 6(4), p 205–225.

D. Patidar and R.S. Rana, Effect of B4C Particle Reinforcement on the Various Properties of Aluminium Matrix Composites: A Survey Paper Mater, Today. Proc., 2017, 4(2), p 2981–2988.

M.O. Bodunrin, K.K. Alaneme, and L.H. Chown, Aluminium Matrix Hybrid Composites: A Review of Reinforcement Philosophies; Mechanical, Corrosion and Tribological Characteristics, J. Mater. Resear. Technol., 2015, 4(4), p 434–445.

R. Seetharam, S.K. Subbu, and M.J. Davidson, Hot Workability and Densification Behavior of Sintered Powder Metallurgy Al-B4C Preforms During Upsetting, J. Manuf. Process., 2017, 28, p 309–318.

R. Clinktan, V. Senthil, K.R. Ramkumar, S. Sivasankaran, and F.A. Al-Mufadi, Effect of Boron Carbide Nano Particles in CuSi4Zn14 Silicone Bronze Nanocomposites on Matrix Powder Surface Morphology and Structural Evolution via Mechanical Alloying, Ceram. Int., 2019, 45, p 3492–3501.

R. Clinktan, V. Senthil, K.R. Ramkumar, S. Sivasankaran, and Fahad A. Al-Mufadi, Influence of B4C Nanoparticles on Mechanical Behaviour of Silicon Brass Nanocomposite Through Mechanical Alloying and Hot Pressing, Ceram. Int., 2019, 45, p 3492–3501.

R. Seetharam, S.K. Subbu, and M.J. Davidson, Microstructure Modeling of Dynamically Recrystallization Grain Size of Al-4%B4C Composite During Hot Upsetting, J. Eng. Mater. Techno., 2018, 1401(2), p 021003.

F. Chen, Z. Cui, and S. Chen, Recrystallization of 30Cr2Ni4MoV Ultra-Super-Critical Rotor Steel During Hot Deformation. Part I: Dynamic Recrystallization, Mater. Sci. Eng. A, 2011, 528, p 5073–5080.

M. Zhou, Y.C. Lin, J. Deng, and Y.Q. Jiang, Hot Tensile Deformation Behaviors and Constitutive Model of an al–zn–mg–cu Alloy, Mater. Des., 2014, 59, p 141–150.

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, and M. He, Dynamic Recrystallization Behavior of a Typical Nickel-Based Superalloy During Hot Deformation, Mater. Des., 2014, 57, p 568–577.

K.S. Tun, W.L. Wong, Q.B. Nguyen, and M. Gupta, Tensile and Compressive Responses of Ceramic and Metallic Nanoparticle Reinforced Mg Composites, Materials, 2013, 6(5), p 1826–1839.

Y.C. Lin, X.Y. Jianga, C.J. Shuai, C.Y. Zhao, D.G. He, M.S. Chen, and C. Chen, Effects of Initial Microstructures on Hot Tensile Deformation Behaviors and Fracture Characteristics of Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2018, 711, p 293–302.

Y.C. Lin, L. Li, D.G. He, M.S. Chen, and G.Q. Liu, Effects of Pre-Treatments on Mechanical Properties and Fracture Mechanism of a Nickel-Based Superalloy, Mater. Sci. Eng. A, 2017, 679, p 401–409.

C. Zener and J.H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–32.

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des, 2011, 32, p 1733–1759.

W.F. Gale and T.C. Totemeier, Smithells metals reference book, 7th ed. Butterworth-Heinemann, Burlington, VT, 1992, p 1929

K.K. Alaneme, E.A. Okotete, V.A. Fajemisin, and M.A. Bodunrin, Applicability of Metallic Reinforcements for Mechanical Performance Enhancement in Metal Matrix Composites: A Review, Arab. J. Basic Appl. Sci., 2019, 26, p 311–330.

W.A. Bryant, Correlation of Data on the Hot Deformation of Ti-6Al-4V, J. Mater. Sci., 1975, 10, p 1793–1797.

A. Momeni and S.M. Abbasi, Effect of Hot Working on Flow Behavior of Ti-6Al-4V alloy in Single Phase and Two-Phase Regions, Mater. Des., 2010, 31, p 3599–3604.

S. Hao et al., Hot Deformation Behaviors of 35%SiCp/2024Al Metal Matrix Composites, Trans. Nonferrous Met. Soc. China., 2014, 24, p 2468–2474.

E. Cerri, S. Spigarelli, E. Evangelista, and P. Cavaliere, Hot Deformation and Processing Maps of a Particulate-Reinforced 6061+20% Al2O3 Composite, Mater. Sci. Eng., 2002, 324, p 157–161.

S. Spigarelli, E. Cerri, P. Cavaliere, and E. Evangelista, An Analysis of Hot Formability of the 6061+20% Al2O3 Composite by Means of Different Stability Criteria, Mater. Sci. Eng. A., 2002, 327, p 144–154.

X.X. Xia, H.J. McQueen, and P. Sakaris, Hot Deformation Mechanisms in a 10 vol% Al2O3 Particle Reinforced 6061 Al Matrix Composite, Scr. Metall. Mater., 1995, 32, p 1185–1190.

Z.Y. Huang, X.X. Zhang, B.L. Xiao, and Z.Y. Ma, Hot Deformation Mechanisms and Microstructure Evolution of SiCp/2014Al Composite, J. Alloys Compd., 2017, 722, p 145–157.

M. Ferry and P.R. Munroe, Hot Working Behaviour of Al-Al2O3 Particulate Reinforced Metal Matrix Composite, Mater. Sci. Technol., 1995, 11(7), p 633.

L. Xiaopu, L. Chongyu, L. Kun, M. Mingzhen, and L. Riping, Hot Deformation Behaviour of SiC/AA6061 Composites Prepared by Spark Plasma Sintering, J. Mater. Sci. & Tech., 2016, 32, p 291–297.

X.X. Xia and H.J. McQueen, Deformation Behaviour and Microstructure of a 20% Al2O3 Reinforced 6061 Al Composite, Appl. Compos. Mater., 1997, 4(6), p 333–347.

X. Wenchen, J. Xueze, X. Wendeng, Z. Xiangqian, and S. Debin, Study on Hot Deformation Behavior and Workability of Squeeze-Cast 20 vol% SiCw/6061Al Composites Using Processing Map, Mater. Charac., 2018, 135, p 154–166.

Matsui T, Takizawa H, Kikuchi H, et al. The Microstructure Prediction of Alloy 720LI for Turbine Disk Applications. 9th International Symposium on Superalloys, Champion, PA, 9–13 Sept 2000, pp. 127–133

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Seetharam, R., Subbu, S.K., Davidson, M.J. et al. Influence of Reinforcement Particles on Dynamically Recrystallized Grain of Hot Upset Sintered Al-B4C Composites. J. of Materi Eng and Perform 31, 9083–9096 (2022). https://doi.org/10.1007/s11665-022-06955-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06955-6