Abstract

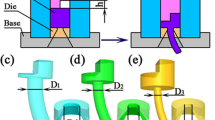

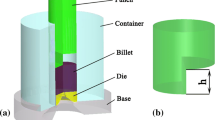

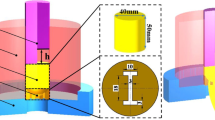

The use of lightweight arc-shaped products is one of the effective ways to realize the lightweight of material and structure. Staggered extrusion (SE) is a new method for short process forming of arc-shaped materials. Due to step-like stem, it has an important influence on extrusion flow behavior and microstructure. Herein, the AZ31 magnesium alloy microstructure evolution during the SE is focused on. By means of metallographic microstructure analysis and electron backscatter diffraction, the microstructure of bending products with staggered distance h of 16 mm and extrusion ratio of 11.11 was analyzed. The results show that with the change of stem structure, the order and amount of shear deformation change at each part, resulting in the difference of average grain size. Compared with the initial billet, the average grain size is refined from 68.38 to 17.15 μm. Complete dynamic recrystallization takes place to form fine and uniform grains. Basal texture {0001} tends to be perpendicular to the extrusion direction (ED) in regions A, B and C. The texture of region A in forward extrusion is shifted counterclockwise, and that of regions B and C in backward extrusion is shifted clockwise. However, the texture in the region D turns parallel to the ED, but there is a small deflection angle α. It provides scientific guidance for the shape control and precision manufacturing of high-quality arc-shaped products.

Similar content being viewed by others

Reference

H. Yang, H. Li, Z. Zhang, M. Zhan, J. Liu and G. Li, Advances and Trends on Tube Bending Forming Technologies, Chin. J. Aeronaut., 2012, 25, p 1–12.

J. Ma and T. Welo, Analytical Springback Assessment in Flexible Stretch Bending of Complex Shapes, Int. J. Mach. Tool Manuf., 2020, 160, p 103653.

I. Oh, S. Han, Y. Woo, J. Ra and Y. Moon, Tubular Blank Design to Fabricate an Elbow Tube by a Push-Bending Process, J. Mater. Process. Technol., 2018, 260, p 112–122.

A. Wang, H. Xue, S. Saud, Y. Yang and Y. Wei, Improvement of Springback Prediction Accuracy for Z-Section Profiles in Four-Roll Bending Process Considering Neutral Layer Shift, J. Manuf. Process., 2019, 48, p 218–227.

S. Chatti, M. Hermes, A. Tekkaya and M. Kleiner, The new TSS Bending Process: 3D Bending of Profiles with Arbitrary Cross-Sections, CIRP Ann., 2010, 59, p 315–318.

Y. Guo, Y. Shi, X. Wang, R. Sun and X. Li, A Method to Realize High-Precision and Large Laser Thermal Bending Angle, J. Manuf. Process., 2021, 62, p 168–178.

B. Li, Z. McClelland, S. Horstemeyer, I. Aslam, P. Wang and M. Horstemeyer, Time Dependent Springback of a Magnesium Alloy, Mater. Des., 2015, 66, p 575–580.

W. Zhou, J. Lin, T. Dean and L. Wang, Analysis and Modelling of a Novel Process for Extruding Curved Metal Alloy Profiles, Int. J. Mech. Sci., 2018, 138–139, p 524.

W. Zhou, Z. Shi and J. Lin, Upper Bound Analysis of Differential Velocity Sideways Extrusion Process for Curved Profiles using a Fan-Shaped Flow Line Model, Int. J. Lightweight Mater. Manuf., 2018, 1, p 21–32.

L. Li, Advanced Extrusion Technology and Application of Aluminium, Chin. J Mech. Eng., 2012, 48, p 35.

Y. Wang, F. Li, W. Shi, X. Li and W. Fang, Microstructure, Bending Behavior and Texture Evolution of AZ31B Magnesium Alloy Bending Products Processed by Staggered Extrusion (SE), Mater. Charact., 2019, 155, p 109842.

Y. Wang, F. Li, X. Li and W. Fang, Effect of Extrusion Ratio on the Bending Behavior, Microstructure and Texture Evolution of AZ31 Magnesium Alloy by the Staggered Extrusion (SE), J. Magnes. Alloys, 2020, 8, p 1304–1313.

Y. Wang, F. Li, W. Shi, X. Li and W. Fang, Dynamic Recrystallization and Metal Flow Behavior of AZ31 Magnesium Alloy Bending Products Processed by Staggered Extrusion, J. Mater. Eng. Perform., 2019, 28, p 3551–3559.

W. Zhou, J. Lin, T. Dean and L. Wang, A Novel Application of Sideways Extrusion to Produce Curved Aluminium Profiles: Feasibility Study, Procedia Eng., 2017, 207, p 2304–2309.

W. Zhou, J. Lin, T. Dean and L. Wang, Feasibility Studies of a Novel Extrusion Process for Curved Profiles: Experimentation and Modelling, Int. J. Mach. Tool Manuf., 2018, 126, p 27–43.

M. Barrnett, Recrystallization During and Following Hot Working of Magnesium Alloy AZ31, Mater. Sci. Forum., 2003, 419–422, p 503.

T. Al-samman, X. Li and S. Chowdhury, Orientation Dependent Slip and Twinning during Compression and Tension of Strongly Textured Magnesium AZ31 Alloy, Mater. Sci. Eng. A, 2010, 527, p 3450–3463.

S. Chen, H. Song, S. Zhang, M. Cheng and M.G. Lee, Effect of Shear Deformation on Plasticity, Recrystallization Mechanism and Texture Evolution of Mg-3Al-1Zn Alloy Sheet: Experiment and Coupled Finite Element-VPSC Simulation, J. Alloy. Compd., 2019, 805, p 138–152.

J. Wu, L. Jin, J. Dong, F. Wang and S. Dong, The Texture and Its Optimization in Magnesium Alloy, J. Mater. Sci. Technol., 2020, 42, p 175–189.

Acknowledgment

This project is supported by the National Natural Science Foundation of China (Grant No. 51975166).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, X., Li, F., Wang, Y. et al. Recrystallization Behavior and Texture Evolution of Magnesium Alloy Bending Products under Staggered Extrusion. J. of Materi Eng and Perform 30, 8108–8116 (2021). https://doi.org/10.1007/s11665-021-06056-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06056-w