Abstract

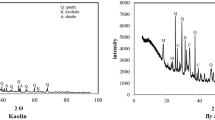

In this study, the effect of nano-TiO2 on the thermomechanical properties of fly ash-based geopolymer prepared by using alkali activator solution in an SiO2/Na2O ratio of 1.1, cured at 80ºC for 24 h, is investigated. The integrity of geopolymer mortars at an elevated temperature was determined by estimating the retention of compressive strength and weight loss of sample subjected to elevated temperatures (30–800°C). Analytical tests such as x-ray diffraction (XRD), attenuated total reflection Fourier transform infrared spectroscopy (ATR FT-IR), dilatometry and thermogravimetric and differential thermal analysis (TGA/DTA) were performed on the geopolymer to ascertain structural and phase changes when the geopolymer is subjected to higher temperatures up to 800ºC. We observed that 2% n-TiO2 admixed mortars (M2) showed enhanced engineering properties at all temperatures studied. TGA/DTA studies confirmed the thermal stability of geopolymers up to 1200°C and the major mass loss occurs due to evaporation of water below 200°C. The mass loss was 7% for M2 and 12% for the control mortars (M1). The thermal expansion values are 1.1% for M1 and 0.04% for M2, respectively. This negligible thermal expansion value for M2 indicated the matrix thermal compatibility between the gel and aggregate to be good so as to retain structural integrity. n-TiO2 stimulates the nucleating sites during gel formation reaction by increasing the dissolution of Si4+ and Al3+ from the original fly ash, resulting in the generation of more amount of binding gel, as confirmed by ATR-FT-IR, XRD and SEM analysis, which may be the reason for the increase in the material’s strength on adding n-TiO2. Fly ash-based geopolymers can therefore be used as a fire-resistant binder, and fire resistance can be further enhanced by addition of n-TiO2. So these binders have a great potential for fire-resistant construction applications.

Graphical Abstract

Similar content being viewed by others

References

J.L. Provis, A. Palomo and C. Shi, Advances in Understanding Alkali-Activated Materials, Cem. Concr. Res., 2015, 78A, p 110–125. https://doi.org/10.1016/j.cemconres.2015.04.013

J.L. Provis, J.S.J. Van Deventer, Alkali-Activated Materials: State-of-the-Art Report, RILEMTC 224-AAM, Springer/RILEM, 2014

C. Shi and J. Qian, High Performance Cementing Materials From Industrial Slags—A Review, Resour. Conserv. Recycle., 2014, 29, p 195–207. https://doi.org/10.1016/S0921-3449(99)00060-9

C. Shi, A. FernAndez-JimEnez and A. Palomo, New Cements for the 21st Century: The Pursuit of an Alternative to Portland Cement, Cem. Concr. Res., 2011, 41, p 750–763. https://doi.org/10.1016/j.cemconres.2011.03.016

S.D. Wang, X.C. Pu, K.L. Scrivener and P.L. Pratt, Alkali-Activated Slag Cement and Concrete: A Review of Properties and Problems, Adv. Cem. Res., 2005, 7, p 93–102. https://doi.org/10.1680/adcr.1995.7.27.93

J Davidovits, Geopolymer Chemistry and Applications, Institut Géopolymère, Saint-Quentin, France, 28, 2008.

P. Duxon, A. Fernandez-Jimenez, J. Provis, G. Luckey, A. Palomo and J. Van Deventer, Geopolymer Technology: The Current State of the Art, J. Mater. Sci., 2007, 42, p 2917–2933. https://doi.org/10.1007/s10853-006-0637-z

D.L.Y. Kong, J.G. Sanjayan and K.S. Crentsil, Comparative Performance of Geopolymers Made with Metakaolin and Fly Ash After Exposure to Elevated Temperatures, Cem. Concr. Res., 2007, 37, p 1583–1589. https://doi.org/10.1016/j.cemconres.2007.08.021

S. Donatello, C. Kuenzel, A. Palomo and A. Fernandez-Jimenez, High Temperature Resistance of a Very High Volume Fly Ash Cement Paste, Cem. Concrete. Comp., 2014, 45, p 234–242. https://doi.org/10.1016/j.cemconcomp.2013.09.010

F. Qu, W. Li, Z. Tao et al., High Temperature Resistance of Fly Ash/GGBFS-Based Geopolymer Mortar with Load-Induced Damage, Mater Struct, 2020, 53, p 111. https://doi.org/10.1617/s11527-020-01544-2

A.M. Rashad and S.R. Zeedan, The Effect of Activator Concentration on the Residual Strength of Alkali Activated Fly Ash Pastes Subjected to Thermal Load, Constr. Build. Mater., 2011, 25, p 3098–3107. https://doi.org/10.1016/j.conbuildmat.2010.12.044

S.A. Bernal, D.E. Mejía, R. Gutierrez and J.L. Provis, Engineering and Durability Properties of Concretes Based on Alkali-Activated Granulated Blast Furnace Slag/Metakaolin Blends, Constr. Build. Mater., 2012, 33, p 99–108. https://doi.org/10.1016/j.conbuildmat.2012.01.017

S.J. Chithambaram, S. Kumar and M.M. Prasad, Thermo-Mechanical Characteristics of Geopolymer Mortar, Constr. Build. Mater., 2019, 213, p 100–108.

S.M. Park, J.G. Jang, N.K. Lee and H.K. Lee, Physiochemical Properties of Binder Gel in Alkali Activated Fly Ash/Slag Exposed to High Temperature, Cem. Concr. Res., 2016, 89, p 72–79. https://doi.org/10.1016/j.cemconres.2016.08.004

L.Y.K. Daniel and J.G. Sanjayan, Damage Behavior of Geopolymer Composites Exposed to Elevated Temperatures, Cem. Concrete. Comp., 2008, 30, p 986–991. https://doi.org/10.1016/j.cemconcomp.2008.08.001

C. Shi, P.V. Krivenko and D.M. Roy, Alkali-Activated Cements and Concrete, Taylor & Francis, London, 2006.

A. Fernández-Jiménez, A. Palomo and M. Criado, Microstructure Development of Alkali-Activated Fly Ash Cement: A Descriptive Model, Cem. Concr. Res., 2005, 35(6), p 1204–1209.

H.T. Nguyen, S.M. Gallardo, T. Bacanif, Q.M. Hirofumi Hinode, M.H. Do, M.A Do Promentilla, Evaluating Thermal Properties of Geopolymer Produced from Red Mud, Rice Husk Ash and Diatomaceous Earth, 6th Regional Conference on Chemical Engineering 49 (2013).

M. RashadAlaa, Effects of ZnO2, ZrO2, CuO3, CuO, CaCO3, SF, FA, Cement and Geothermal Silica Waste Nanoparticles on Properties of Cementitious Materials—A Short Guide for Civil Engineer, Constr. Build. Mater., 2013, 48, p 1120–1123. https://doi.org/10.1016/j.conbuildmat.2013.06.083

A. Nazari and S. Riahi, The Role of SiO2 Nanoparticles and Ground Granulated Blast Furnace Slag Admixtures on Physical, Thermal and Mechanical Properties of Self Compacting Concrete, Mater. Sci. Eng.: A, 2011, 528, p 2149–2157.

Z. Min-Hong, I. Jahidul and P. Sulapha, Use of Nano-Silica to Increase Early Strength and Reduce Setting Time of Concretes with high Volumes of Slag, Cem. Concr. Compos., 2012, 34, p 650–662. https://doi.org/10.1016/j.cemconcomp.2012.02.005

O. Meral and S. Remzi, Effect of Nano-SiO2, Nano-Al2O3 and Nano-Fe2O3 Powders on Compressive Strengths and Capillary Water Absorption of Cement Mortar Containing Fly Ash: A Comparative Study, Energy Build., 2013, 58, p 292–301. https://doi.org/10.1016/j.enbuild.2012.12.014

F. Shaikh and S. Haque, Behaviour of Carbon and Basalt Fibres Reinforced Fly Ash Geopolymer at Elevated Temperatures, Int. J. Concr. Struct. Mater., 2018, 12(1), p 1–12.

P. Behera, V. Baheti, J. Militky and P. Louda, Elevated Temperature Properties of Basalt Microfibril Filled Geopolymer Composites, Constr. Build. Mater., 2018, 163, p 850–860.

S. Ishak, H.S. Lee, J.K. Singh, M.A.M. Ariffin, N.H.A.S. Lim and H.M. Yang, Performance of Fly Ash Geopolymer Concrete Incorporating Bamboo Ash at Elevated Temperature, Materials, 2019, 12(20), p 3404.

H. Assaedi, F. Shaikh and I. Low, Characterizations of Flax Fabric Reinforced Nanoclay-Geopolymer Composites, Compos. B Eng., 2016, 95, p 412–422. https://doi.org/10.1016/j.compositesb.2016.04.007

M. Oltulu and R. Shahin, Single and Combined Effects of Nano-SiO2, Nano-Al2O3 and Nano-Fe2O3 Powders on Compressive Strength and Capillary Permeability of Cement Mortar Containing Silica Fume, Mater. Sci. Eng A., 2011, 528, p 7012–7019. https://doi.org/10.1016/j.msea.2011.05.054

H. Assaedi, F.U.A. Shaikh and I. Low, Effect of Nano-Clay on Mechanical and Thermal Properties of Geopolymer, Integr. Med. Res., 2016, 4, p 19–28. https://doi.org/10.1016/j.jascer.2015.10.004

P. Duan, C. Yan, W. Luo and W. Zhou, Effects of Adding Nano-TiO2 on Compressive Strength, Drying Shrinkage, Carbonation and Microstructure of Fluidized Bed Fly Ash Based Geopolymer Paste, Constr. Build. Mater., 2016, 106, p 115–125. https://doi.org/10.1016/j.conbuildmat.2015.12.095

P. Timakul, W. Rattanaprasit and P. Aungkavattana, Enhancement of Compressive Strength and Thermal Shock resistance of Fly Ash-Based Geopolymer Composites, Constr. Build. Mater., 2016, 121, p 653–658. https://doi.org/10.1016/j.conbuildmat.2016.06.037

Z. Zidi, M. Ltifi and I. Zafar, Synthesis and Attributes of Nano-SiO2 Local Metakaolin Based-Geopolymer, J. Build. Eng., 2021, 33, p 101586.

Z. Zidi, M. Ltifi, Z. Ben Ayadi, L. EL Mir and X.R. Nóvoa, Effect of Nano-ZnO on Mechanical and Thermal Properties of Geopolymer, J. Asian Ceram. Soc., 2020, 8(1), p 1–9. https://doi.org/10.1080/21870764.2019.1693682

O.H. Li, L. Yun-Ming, H. Cheng-Yong, R. Bayuaji, M.M.A.B. Abdullah, F.K. Loong, T.S. Jin, N.H. Teng, M. Nabiałek, B. Jeż and N.Y. Sing, Evaluation of the Effect of Silica Fume on Amorphous Fly Ash Geopolymers Exposed to Elevated Temperature, Magnetochemistry, 2021, 7(1), p 9.

M. Sivasakthi, R. Jeyalakshmi, N.P. Rajamane and R. Jose, Thermal and structural micro analysis of micro silica blended fly ash based geopolymer composites, J. Non-Crystall. Solids, 2018, 499, p 117–130. https://doi.org/10.1016/j.jnoncrysol.2018.07.027

ASTM E 831-03. Standard test method for linear thermal expansion of solid materials by thermomechanical analysis. ASTM International, 2003, 15.

C. Alonso and L. Fernandez, Dehydration and Rehydration Processes of Cement Paste Exposed to High Temperature Environments, J. Mater. Sci., 2004, 39, p 3015–3024. https://doi.org/10.1023/B:JMSC.0000025827.65956.18

G. Debicki, R. Haniche and F. Delhomme, An Experimental Method for Assessing the Spalling Sensitivity of Concrete Mixture Submitted to High Temperature, Cem. Concr. Compos., 2012, 34, p 958–963. https://doi.org/10.1016/j.cemconcomp.2012.04.002

S. Donatello, C. Kuenzel, A. Palomo and A. Fernandez-Jimenez, High Temperature Resistance of a Very High Volume Fly Ash Cement Paste, Cem. Concr. Compos., 2014, 45, p 234–242. https://doi.org/10.1016/j.cemconcomp.2013.09.010

J. Temuujin, A. Van Riessen and K.J.D. MacKenzie, Preparation and Characterization of Fly Ash Based Geopolymer Mortars, Constr. Build. Mater., 2010, 24, p 1906–1910. https://doi.org/10.1016/j.conbuildmat.2010.04.012

K.K. Mandal, S. Thokchom and M. Roy, Effect of Na2O Content on Performance of Fly Ash Geopolymers at Elevated Temperature, Int. J. Environ. Chem. Ecol. Geol. Geophys. Eng., 2011, 5, p 7–13.

D.L. Kong and J.G. Sanjayan, Effect of Elevated Temperatures on Geopolymer Paste, Mortar and Concrete, Cem. Concr. Res., 2010, 40(2), p 334–339. https://doi.org/10.1016/j.cemconres.2009.10.017

J.G.S. Van Jaarsveld, J.S.J. Van Deventer and G.C. Lukey, The Characterisation of Source Materials in Fly Ash-Based Geopolymers, Mater. Lett., 2003, 57(7), p 1272–1280. https://doi.org/10.1063/1.5003524

D. Hou, Y. Zhang, T. Yang, J. Zhang, H. Pei, J. Zhang, J. Jiang and T. Li, Molecular Structure, Dynamics, and Mechanical Behavior of Sodium Aluminosilicate Hydrate (NASH) Gel at Elevated Temperature: A Molecular Dynamics Study, Phys. Chem. Chem. Phys., 2018, 20(31), p 20695–20711.

J.G.S. Van Jaarsveld, J.S.J. Van Deventer and A. Schwartzman, The potential use of geopolymeric materials to immobilise toxic metals: Part II Material and Leaching Characteristics, Miner. Eng., 1999, 12(1), p 75–91. https://doi.org/10.1016/S0892-6875(98)00121-6

A. Fernández-Jiménez and A. Palomo, Characterisation of fly ashes. Potential Reactivity as Alkaline Cements, Fuel, 2003, 82, p 2259–2265. https://doi.org/10.1016/S0016-2361(03)00194-7

A. Palomo, P.F.G. Banfill, A. Fernandéz-Jiménez and D.S. Swift, Properties of Alkali-Activated Fly Ashes Determined from Rheological Measurements, Adv. Cem. Res., 2005, 17, p 143–151. https://doi.org/10.1680/adcr.2005.17.4.143

A. Fernandez-Jimenez, A.G. de la Torre, A. Palomo, G. Lopez-Olmo, M.M. Alonso and M.A.G. Aranda, Alkali Activated Fly Ash Binders. Part II the degree of reaction, Fuel, 2006, 85, p 625–634.

S. Kumar, R. Kumar, T.C. Alex, A. Bandopadhyay and S.P. Mehrotra, Influence of Reactivity of Fly Ash on Geopolymerisation, Adv. Appl. Ceram., 2007, 106, p 120–127. https://doi.org/10.1179/174367607X159293

J.L. Provis, R.M. Harrex, S.A. Bernal, P. Duxson and J.S.J. Van Deventer, Dilatometry of Geopolymers as a Means of Selecting Desirable Fly Ash Sources, J. Non-Cryst. Solids., 2012, 358, p 1930–1937. https://doi.org/10.1016/j.jnoncrysol.2012.06.001

J.L. Provis, C.Z. Yong, P. Duxson and J.S.J. Van Deventer, Correlating Mechanical and Thermal Properties of Sodium Silicate-fly Ash Geopolymers, Colloids. Surf A: Physicochem. Eng. Aspects, 2009, 336, p 57–63. https://doi.org/10.1016/j.colsurfa.2008.11.019

W.D. Rickard, J. Temuujin and A. Van Riessen, Thermal Analysis of Geopolymer Pastes Synthesised from Five Fly Ashes of Variable Composition, J. Non-Cryst. Solids., 2012, 358, p 1830–1839. https://doi.org/10.1016/j.jnoncrysol.2012.05.032

K.Onaran Materials science (Malzeme Bilimi). I˙ stanbul, Turkey: Science Technical Press; 1993 (p. 174) [In Turkish].

A.G. London, The Thermal Properties of Lightweight Concretes, Int. J. Cem. Compos. Lightw. Concr., 1979, 1, p 71–85. https://doi.org/10.1016/0262-5075(79)90013-7

X. Fu and D.D.L. Chung, Effect of admixtures on the thermal and thermomechanical behavior of cement paste, ACI Mater. Jour., 1999, 96, p 455–461.

K. Zheng, L. Chen and M. Gbozee, Thermal Stability of Geopolymers used as Supporting Materials for TiO2 Film Coating Through Sol-gel Process: Feasibility and Improvement, Const. Build. Mater., 2016, 25, p 1114–1126. https://doi.org/10.1016/j.conbuildmat.2016.09.007

W.K.W. Lee and J.S.J. Van Deventer, The Use of Infrared Spectroscopy to Study Geopolymerisation of Heterogeneous Amorphous Aluminosilicates, Langmuir, 2003, 19, p 8726–8734. https://doi.org/10.1021/la026127e

F. Skvara, L. Kopecky, V. Amilauer and Z. Bitnaar, Material and Structural Characterization of Alkali Activated Low-Calcium Brown Coal Fly Ash, J. Hazard. Mater., 2009, 168, p 711–720. https://doi.org/10.1016/j.jhazmat.2009.02.089

A. Palomo, M.W. Grutzeck and M.T. Blanco, Alkali-Activated Fly Ashes: A Cement for the Future, Cem. Concr. Res., 1999, 29, p 1323–1329. https://doi.org/10.1016/S0008-8846(98)00243-9

E. Prud’homme, P. Michaud, E. Joussein, A. Smith, C. Peyratout, I. Sobrados, J. Sanz and S. Rossignol, Geomaterial Foams: Role Assignment of Raw Materials in the Network Formation, J. Sol-gel Sci. Technol., 2012, 61(2), p 436–448. https://doi.org/10.1007/s10971-011-2644-z

M. Criado, A. Fernández-Jiménez and A. Palomo, Alkali Activation of Fly Ash: Effect of the SiO2/Na2O ratio: Part I: FTIR study, Microp. Mesop. Mater., 2007, 106(1–3), p 180–191. https://doi.org/10.1016/j.micromeso.2007.02.055

J.L. Provis, G.C. Lukey and J.S.J. Van Deventer, Do Geopolymers Actually Contain Nanocrystalline Zeolites? A Reexamination of Existing Results, Chem. Mater., 2005, 2005(17), p 3075–3085. https://doi.org/10.1021/cm050230i

Acknowledgments

This work was supported by Department of Science and Technology under TDP section [Grant no DST/TSG/STS/2012/20].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sivasakthi, M., Jeyalakshmi, R. & Rajamane, N.P. Investigation of Microstructure and Thermomechanical Properties of Nano-TiO2 Admixed Geopolymer for Thermal Resistance Applications. J. of Materi Eng and Perform 30, 3642–3653 (2021). https://doi.org/10.1007/s11665-021-05708-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05708-1