Abstract

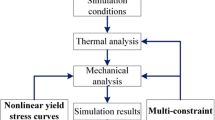

In the past decades, thin-plate weldments have been increasingly used in various engineering structures to meet the requirements of lightweight. However, deformation induced by welding process has a negative effect on assembly accuracy and structural integrity. Therefore, it is critical to predict welding deformation and then to control or reduce the total deformation. Because the thermal elastic plastic FEM has the advantage of high computational accuracy, an attempt was made to predict the welding deformation of a large-scale thin-plate welded structure in this study. Based on the commercial software MSC. Marc, a thermal elastic plastic FEM with the consideration of material nonlinearity, geometrical nonlinearity, and boundary nonlinearity was developed to simulate the welding deformation of large-scale welded structures. The effectiveness of the developed computational approach was verified by the experimental measurements. Moreover, the mechanism of buckling distortion in a large-scale stiffened panel structure was investigated based on the simulated results. In addition, the influences of heat input, welding procedures, and constraint condition on welding deformation were also examined numerically.

Similar content being viewed by others

References

D. Deng and H. Murakawa, FEM Prediction of Buckling Distortion Induced by Welding in Thin Plate Panel Structures, Comput. Mater. Sci., 2008, 43(4), p 591–607. https://doi.org/10.1016/j.commatsci.2008.01.003

W. Liang and D. Deng, Influences of Heat Input, Welding Sequence and External Restraint on Twisting Distortion in an Asymmetrical Curved Stiffened Panel, Adv. Eng. Softw., 2018, 115, p 439–451. https://doi.org/10.1016/j.advengsoft.2017.11.002

W. Liang, X. Hu, Y. Zheng, and D. Deng, Determining Inherent Deformations of HSLA Steel T-Joint under Structural Constraint by Means of Thermal Elastic Plastic FEM, Thin-Walled Struct., 2020, 147, p 106568. https://doi.org/10.1016/j.tws.2019.106568

Z. Li, J. Liu, S. Ren, S. Li, and D. Deng, Influences of Dimension Factors on Residual Stress and Welding Distortion in SUS304 Stainless Steel Butt Joint, J. Mech. Eng., 2018, 54(10), p 59.

C.A. Fernandes, N.L. do Vale, T.F. de Abreu Santos, and S.L. Urtiga Filho, Investigation of Transverse Shrinkage and Angular Distortion Caused by Hybrid Laser-Arc Welding, Int. J. Adv. Manuf. Technol., 2020, 107(11–12), p 4705–4711, doi:https://doi.org/10.1007/s00170-020-05343-5.

D. Deng, Y. Zhou, T. Bi, and X. Liu, Experimental and Numerical Investigations of Welding Distortion Induced by CO2 Gas Arc Welding in Thin-Plate Bead-on Joints, Mater. Des., 2013, 52(24), p 720–729. https://doi.org/10.1016/j.matdes.2013.06.013

M. Hashemzadeh, Y. Garbatov, and C. Guedes soares, Analytically Based Equations for Distortion and Residual Stress Estimations of Thin Butt-Welded Plates, Eng. Struct., 2017, 137, p 115–124. https://doi.org/10.1016/j.engstruct.2017.01.041

W. Zhao, S. Li, J. Ding, Y. Wei, X. Liu, and S. Song, Building Framework for Selecting Finite Element Models of Complex Large Welded Structure of Railway Vehicles, Simul. Model. Pract. Theory, 2019, 97, p 101950. https://doi.org/10.1016/j.simpat.2019.101950

Y. Ye, J. Cai, X. Jiang, D. Dai, and D. Deng, Influence of Groove Type on Welding-Induced Residual Stress, Deformation and Width of Sensitization Region in a SUS304 Steel Butt Welded Joint, Adv. Eng. Softw., 2015, 86, p 39–48. https://doi.org/10.1016/j.advengsoft.2015.04.001

T. Bajpei, H. Chelladurai, and M.Z. Ansari, Experimental Investigation and Numerical Analyses of Residual Stresses and Distortions in GMA Welding of Thin Dissimilar AA5052-AA6061 Plates, J. Manuf. Process., 2017, 25, p 340–350. https://doi.org/10.1016/j.jmapro.2016.12.017

J. Liu, Z. Li, S. Ren, W. Liang, and D. Deng, Investigating the Mechanism of Out-of-Plane Deformation in Q345 Steel Single-Pass Bead-on Welded Joint with External Restraint, J. Mech. Eng., 2018, 54(14), p 90–97. https://doi.org/10.3901/JME.2018.14.090

G. Fu, S.F. Estefen, T. Gurova, and M.I. Lourenco, Effect of Material Model on Residual Stress and Distortion in T-Joint Welding, Ships Offshore Struct., 2018, 13(1), p 56–64. https://doi.org/10.1080/17445302.2017.1342894

M.S. Yi, D.H. Lee, H.H. Lee, and J.K. Paik, Direct Measurements and Numerical Predictions of Welding-Induced Initial Deformations in a Full-Scale Steel Stiffened Plate Structure, Thin-Walled Struct., 2020, 153, p 106786. https://doi.org/10.1016/j.tws.2020.106786

S. Suman, A. Tiwari, P. Pankaj, P. Biswas, B. Kuriachen, and A. Sinha, Modelling of Welding Sequences for Minimization of Weld-Induced Distortions and Residual Stresses, Adv. Addit. Manuf. Join., 2020 https://doi.org/10.1007/978-981-32-9433-2_53

S. Suman and P. Biswas, Numerical Study of Welding Distortion in SAW Welded Creep Strength Enhanced Ferrite Steel Joint, Adv. Mech. Eng., 2020 https://doi.org/10.1007/978-981-15-0124-1_57

D. Deng, H. Murakawa, and W. Liang, Numerical Simulation of Welding Distortion in Large Structures, Comput. Methods Appl. Mech. Eng., 2007, 196(45–48), p 4613–4627. https://doi.org/10.1016/j.cma.2007.05.023

D. Deng, H. Murakawa, and M. Shibahara, Investigations on Welding Distortion in an Asymmetrical Curved Block by Means of Numerical Simulation Technology and Experimental Method, Comput. Mater. Sci., 2010, 48(1), p 187–194. https://doi.org/10.1016/j.commatsci.2009.12.027

J. Wang, S. Rashed, H. Murakawa, and Y. Luo, Numerical Prediction and Mitigation of Out-of-Plane Welding Distortion in Ship Panel Structure by Elastic FE Analysis, Mar. Struct., 2013, 34(4), p 135–155. https://doi.org/10.1016/j.marstruc.2013.09.003

J. Wang, N. Ma, and H. Murakawa, An Efficient FE Computation for Predicting Welding Induced Buckling in Production of Ship Panel Structure, Mar. Struct., 2015, 41, p 20–52. https://doi.org/10.1016/j.marstruc.2014.12.007

X. Pu, C. Zhang, S. Li, and D. Deng, Simulating Welding Residual Stress and Deformation in a Multi-Pass Butt-Welded Joint Considering Balance between Computing Time and Prediction Accuracy, Int. J. Adv. Manuf. Technol., 2017, 93(5–8), p 2215–2226. https://doi.org/10.1007/s00170-017-0691-5

J. Goldak, A. Chakravarti, and M. Bibby, A New Finite Element Model for Welding Heat Sources, Metall. Trans. B, 1984, 15(2), p 299–305. https://doi.org/10.1007/BF02667333

D. Deng and H. Murakawa, Prediction of Welding Distortion and Residual Stress in a Thin Plate Butt-Welded Joint, Comput. Mater. Sci., 2008, 43(2), p 353–365. https://doi.org/10.1016/j.commatsci.2007.12.006

D. Deng, X. Liu, J. He, and W. Liang, Investigating the Influence of External Restraint on Welding Distortion in Thin-Plate Bead-on Joint by Means of Numerical Simulation and Experiment, Int. J. Adv. Manuf. Technol., 2016, 82(5–8), p 1049–1062.

Z. Li, J. Li, Z. Chen, J. Guo, Y. Zhu, and Y. Luo, Experimental and Computational Study on Thermo-mechanical Fatigue Life of Aluminium Alloy Piston, Fatigue Fract. Eng. Mater. Struct., 2021, 44(1), p 141–155. https://doi.org/10.1111/ffe.13342

Y. Ueda, H. Murakawa, and N. Ma, Welding Deformation and Residual Stress of the Numerical Calculation Methods and Procedures, (Chengdu), Sichuan University Press, Sichuan, 2008.

D. Deng, Influence of Deposition Sequence on Welding Residual Stress and Deformation in an Austenitic Stainless Steel J-Groove Welded Joint, Mater. Des., 2013, 49, p 1022–1033. https://doi.org/10.1016/j.matdes.2013.02.065

Z. Li, Study on Prediction of Welding Deformation in Thin-Plate Q235 Steel Structure and Prevention of Buckling Distortion, Chongqing University, Chongqing, 2018.

J. Wang, X. Yin, and H. Murakawa, Experimental and Computational Analysis of Residual Buckling Distortion of Bead-on-Plate Welded Joint, J. Mater. Process. Technol., 2013, 213(8), p 1447–1458. https://doi.org/10.1016/j.jmatprotec.2013.02.009

D. Sun and H. Chen, “New Marc Example Tutorials and Common Problem Analysis,” second ed, (Beijing City), China Water Conservancy and Hydropower Press, (2016).

S.P. Timoshenko and J.M. Gere, Theory of Elastic Stability, Courier Corporation, North Chelmsford, 2009.

P. Mollicone, D. Camilleri, and T. Gray, Procedural Influences on Non-Linear Distortions in Welded Thin-Plate Fabrication, Thin-Walled Struct., 2008, 46(7–9), p 1021–1034. https://doi.org/10.1016/j.tws.2008.01.044

J.-U. Park, H.-W. Lee, and H.-S. Bang, Effects of Mechanical Constraints on Angular Distortion of Welding Joints, Sci. Technol. Weld. Join., 2002, 7(4), p 232–239. https://doi.org/10.1179/136217102225004266

N. Ma, H. Huang, and H. Murakawa, Effect of Jig Constraint Position and Pitch on Welding Deformation, J. Mater. Process. Technol., 2015, 221, p 154–162. https://doi.org/10.1016/j.jmatprotec.2015.02.022

N. Ma and H. Huang, Efficient Simulation of Welding Distortion in Large Structures and Its Reduction by Jig Constraints, J. Mater. Eng. Perform., 2017, 26(11), p 5206–5216. https://doi.org/10.1007/s11665-017-3000-4

A.R. Gharib, F.R. Biglari, M. Shafaie, and A.H. Kokabi, Experimental and Numerical Investigation of Fixture Time on Distortion of Welded Part, Int. J. Adv. Manuf. Technol., 2019, 104(1–4), p 1121–1131. https://doi.org/10.1007/s00170-019-03874-0

Acknowledgments

This work was supported by the National Natural Science Foundation of China [Grant numbers 51875063, 51905055] and the Fundamental Research Funds for the Central Universities Project [Grant numbers 2019CDXYCL0031, 2020CDJ-LHZZ-086].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Z., Feng, G., Deng, D. et al. Investigating Welding Distortion of Thin-Plate Stiffened Panel Steel Structures by Means of Thermal Elastic Plastic Finite Element Method. J. of Materi Eng and Perform 30, 3677–3690 (2021). https://doi.org/10.1007/s11665-021-05646-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05646-y