Abstract

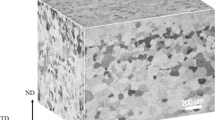

In the present study, effect of multistep cross rolling (MSCR) on microstructure, texture, and magnetic properties has been investigated for UNS S32101 steel. UNS S32101 steel consisting of almost equal proportion of ferrite and austenite was 80% cold cross rolled in multiple steps. The microstructures were characterized using optical microscopy (OM), scanning electron microscopy (SEM), and electron backscattered diffraction (EBSD), while crystallographic texture was determined by x-ray diffraction (XRD). Microstructure showed decrease in band thickness and spacing for both austenite and ferrite with increased cold-rolling reduction. Lenticular bulges were the main feature of microstructure after 80% cold rolling, indicating the presence of strain-induced martensite (SIM). Hysteresis loops were also measured in order to characterize other parameters associated with deformation and SIM. The magnetic anisotropy decreased, while coercivity (Hc), area under the B-H loop and magnetic losses increased with an increase in cold-rolling reduction. Hc was found to be directly proportional to the amount of reduction during cold rolling and inversely proportional to equivalent circle grain size. As-received sample showed strong cube ({100}< 100 >) with strong Brass ({110}< 112 >) in austenite and strong α (rolling direction, RD//< 110 >) and γ (normal direction, ND//< 111 >) fibers in ferrite. For 80% rolling, strong Brass and Goss ({110}< 001 >) were developed in austenite, while strong rotated cube ({100)< 110 >) and γ-fiber were obtained in ferrite.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

M. Breda, K. Brunelli, F. Grazzi, A. Scherillo and I. Calliari, Effects of Cold Rolling and Strain-Induced Martensite Formation in a SAF 2205 Duplex Stainless Steel, Metall. Mater. Trans. A, 2015, 46, p 577–586.

J. Michalska and M. Sozańska, Qualitative and Quantitative Analysis of σ and χ Phases in 2205 Duplex Stainless Steel, Mater. Charact., 2006, 56, p 355–362.

A. Kashiwar, N.P. Vennela, S.L. Kamath and R.K. Khatirkar, Effect of Solution Annealing Temperature on Precipitation in 2205 Duplex Stainless Steel, Mater. Charact., 2012, 74, p 55–63.

R. Gunn, Duplex Stainless Steels- Microstructure, Properties and Applications, Abington Publishing, Cambridge, 1997.

J. Charles, Duplex Stainless Steels, a Review After DSS’07 in Grado, Steel Res. Int., 2008, 79, p 455–465.

I. Alvarez-Armas, Duplex Stainless Steels: Brief History and Some Recent Alloys, Recent Patents Mech. Eng., 2008, 1, p 51–57.

H. Sieurin, R. Sandström and E.M. Westin, Fracture Toughness of the Lean Duplexstainless Steel LDX 2101, Metall. Mater. Trans. A, 2006, 37, p 2975–2981.

S. Baldo and I. Mészáros, Effect of Cold Rolling on Microstructure and Magnetic Properties in a Metastable Lean Duplex Stainless Steel, J. Mater. Sci., 2010, 45, p 5339–5346.

A. Kumar, R.K. Khatirkar, D. Chalapathi, G. Kumar and S. Suwas, Microstructure and Texture Development during Cold Rolling in UNS S32205 and UNS S32760 Duplex Stainless Steels, Metall. Mater. Trans. A, 2017, 48(5), p 2349.

A. Kumar, R.K. Khatirkar, A. Gupta, S.K. Shekhawat and S. Suwas, Deciphering the Possible Role of Strain Path on the Evolution of Microstructure, Texture, and Magnetic Properties in a Fe-Cr-Ni Alloy, Metall. Mater. Trans. A, 2018, 49(8), p 3402.

T.H. Chen and J.R. Yang, Effects of Solution Treatment and Continuous Cooling on σ-Phase Precipitation in a 2205 Duplex Stainless Steel, Mater. Sci. Eng. A, 2001, 311(1–2), p 28–41.

S.S.M. Tavares, M.R. da Silva, J.M. Pardal, H.F.G. Abreu and A.M. Gomes, Microstructural Changes Produced by Plastic Deformation in the UNS S31803 Duplex Stainless Steel, J. Mater. Process. Technol., 2006, 180(1–3), p 318–322.

S. Pramanik, S. Bera and S.K. Ghosh, Influence of Cold Rolling on Microstructural Evolution in 2205 Duplex Stainless Steel, Steel Res. Int., 2013, 85, p 776–783.

R.K. Ray and S. Suwas, Crystallographic Texture of Materials, Springer, Manchester, 2014.

B. Verlinden, J. Driver, I. Samajdar and R. Doherty, Thermo-Mechanical Processing of Metallic Materials, Elsevier, New York, 2007.

C. Herrera, D. Ponge and D. Raabe, Design of a Novel Mn-Based 1 GPa Duplex Stainless TRIP Steel with 60% Ductility by a Reduction of Austenite Stability, Acta Mater., 2011, 59, p 4653–4664.

E.A. Calnan, Deformation Textures of Face-Centred Cubic Metals, Acta Metall., 1954, 2, p 865–874.

M. Holscher, D. Raabe and K. Lucke, Rolling and Recrystallization Textures of Bcc Steels, Steel Res., 1991, 62, p 567–575.

I. Samajdar, B. Verlinden and P. Van Houtte, Development of Recrystallization Texture in IF-Steel an Effort to Explain Developments in Global Texture from Microtextural Studies, Acta Mater., 1998, 46, p 2751–2763.

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, Elsevier, Oxford, 2015.

P.P. Bhattacharjee and R.K. Ray, Effect of Processing Variables on Cube Texture Formation in Powder Metallurgically Prepared Ni and Ni-W Alloy Tapes for Use as Substrates for Coated Conductor Applications, Mater. Sci. Eng. A, 2007, 459, p 309–323.

R.K. Ray and P.P. Bhattacharjee, Enhancement of Cube Texture in Ni by the Addition of W or Mo, Phil. Mag., 2007, 87, p 2417–2426.

T. Leffers and R.K. Ray, The Brass-Type Texture and its Deviation from the Copper-Type Texture , Prog. Mater. Sci., 2009, 54, p 351–396.

E. El-Danaf, S.R. Kalidindi, R.D. Doherty and C. Necker, Deformation Texture Transition in Brass-Critical Role of Micro-Scale Shear Bands, Acta Mater., 2000, 48, p 2665–2673.

R. Madhavan, R.K. Ray and S. Suwas, Texture Transition in Cold-Rolled Nickel–40 wt.% Cobalt Alloy, Acta Mater., 2014, 78, p 222–235.

N. Jia, F. Roters, P. Eisenlohr, C. Kords and D. Raabe, Non-crystallographic Shear Banding in Crystal Plasticity FEM Simulations: Example of Texture Evolution in α-Brass, Acta Mater., 2012, 60, p 1099–1115.

S. Suwas and A.K. Singh, Role of Strain Path Change in Texture Development , Mater. Sci. Eng. A, 2003, 356, p 368–371.

N.P. Gurao, S. Sethuraman and S. Suwas, Effect of Strain Path Change on the Evolution of Texture and Microstructure During Rolling of Copper and Nickel , Mater. Sci. Eng. A, 2011, 528, p 7739–7750.

S. Wronski, M. Wrobel, A. Baczmanski and K. Wierzbanowski, Effects of Cross-Rolling on Residual Stress, Texture and Plastic Anisotropy in Fcc and Bcc Metals, Mater. Charact., 2013, 77, p 116–126.

A. Bocker, H. Klein and H.J. Bunge, Development of Cross-Rolling Textures in Armco-Iron, Textures Microstruct., 1970, 12, p 155–174.

Standard practice for preparation of metallographic specimens 1995 E3-95 (PA, USA: ASTM)

D. Aliya, B. L. Adams, and D. Alman, ASM Handbook Volume 9 Metallography and Microstructures. ASM International, 2018

OIM: Analysis Version 7.2. User Manual, TexSEM Laboratories Inc., Draper, 2013

M.M. Nowell and S.I. Wright, Orientation Effects on Indexing of Electron Backscatter Diffraction Patterns, Ultramicroscopy, 2005, 103(1), p 41–58.

F. Xlong and B.A. Parker, The Determination of Complete Pole Figures Using the Reflection Method, Textures Microstruct., 1984, 6, p 125–135.

F. Bachmann, R. Hielscher and H. Schaeben, Texture Analysis with MTEX–Free and Open Source Software Toolbox Solid State Phenomena, Trans. Tech. Publ., 2010, 5, p 39.

J. Niagaj and Ł Mazur, Ferrite Content Measurements in S32101 Lean Duplex Stainless Steel and Its Welded Joints, Archiv. Metall. Mater., 2012, 57(3), p 780–787.

M. Calcagnotto, D. Ponge, E. Demir and D. Raabe, Orientation Gradients and Geometrically Necessary Dislocations in Ultrafine Grained Dual-Phase Steels Studied by 2D and 3D EBSD, Mater. Sci. Eng. A, 2010, 527(10–11), p 2738–2746.

R. Kim, C. Bae and J. Kim, Initial Deformation Behaviors in Lean Duplex Stainless Steel, Metals, 2020, 10, p 936.

G. Wassermann, The Influence of Mechanical Twinning on the Formation of the Texture in Cubic Metals, Z. Met., 1963, 54, p 61–65.

N. Jia, P. Eisenlohr, F. Roters, D. Raabe and X. Zhao, Orientation Dependence of Shear Banding in Face-Centered-Cubic Single Crystals, Acta Mater., 2012, 60, p 3415–3434.

L. Anand and C. Su, A Theory for Amorphous Viscoplastic Materials Undergoing Finite Deformations, with Application to Metallic Glasses, J. Mech. Phys. Solids., 2005, 53, p 1362–1396.

T. Leffers and A.G. Jensen, Development of Rolling Texture in Copper and Brass, Trans. Met. Soc. AIME, 1968, 242, p 314.

K. Wierzbanowski, M. Wroński and T. Leffers, FCC Rolling Textures Reviewed in the Light of Quantitative Comparisons Between Simulated and Experimental Textures FCC Rolling Textures Reviewed in the Light of Quantitative Comparisons Between Simulations, Crit. Rev. Solid State Mater. Sci., 2014, 39, p 391–422.

J.G. Sevillano, The Contribution of Macroscopic Shear Bands to the Rolling Texture of Fcc Metals, Science, 1977, 11, p 581–585.

B.J. Duggan, M. Hatherly, W.B. Hutchinson and P.T. Wakefield, Deformation Structures and Textures in Cold-Rolled 70: 30 Brass, Met. Sci., 1978, 12, p 343–351.

W.B. Hutchinson, B.J. Duggan and M. Hatherly, Development of Deformation Texture and Microstructure in Cold-Rolled Cu-30Zn, Met. Technol., 1979, 6, p 398–403.

S.R. Kalidindi, R.D. Doherty and C. Necker, Deformation Texture Transition in Brass: Critical Role of Micro-Scale Shear Bands, Acta Mater., 2000, 48, p 2665–2673.

S.R. Kalidindi, Modelling Anisotropic Strain Hardening and Deformation Textures in Low Stacking Fault Energy Fcc Metals, Int. J. Plast., 2001, 17, p 837–860.

S.-H. Hong and D.N. Lee, Deformation and Recrystallization Textures in Cross-Rolled Copper Sheet, Trans. ASME, 2002, 124(1), p 13–22.

P.P. Bhattacharjee, S. Saha and J.R. Gatti, Effect of Change in Strain Path During Cold Rolling on the Evolution of Microstructure and Texture in Al and Al-2.5%Mg, J. Mater. Eng. Perform., 2014, 23, p 458–468.

P.P. Bhattacharjee, M. Joshi, V.P. Chaudhary, J.R. Gatti and M. Zaid, Texture Evolution During Cross-Rolling and Annealing of High Purity Nickel, Metall. Mater. Trans. A, 2013, 44, p 2707–2716.

P.P. Bhattacharjee, M. Joshi, V.P. Chaudhary and M. Zaid, The Effect of Starting Grain Size on the Evolution of Microstructure and Texture in Nickel During Processing by Cross-Rolling, Mater. Charact., 2013, 76, p 2127.

A. Kumar, R.K. Khatirkar, D. Chalapathi, N. Bibhanshu and S. Suwas, Texture Development During Cold Rolling of Fe-Cr-Ni Alloy-Experiments and Simulations, Phil. Mag., 2017, 97, p 1939–1962.

A. Kumar, A. Gupta, R.K. Khatirkar and S. Suwas, Texture Development During Cross Rolling of a Dual Phase Fe-Cr-Ni Alloy: Experiments and Simulations, Philos. Mag. Lett., 2018, 98, p 17–26.

E.J. Gutierrez-Castaneda and A. Salinas-Rodrıguez, Effect of Annealing Prior to Cold Rolling on Magnetic and Mechanical Properties of Low Carbon Non-oriented Electrical Steels, J. Mag. Mag. Mater., 2011, 323, p 2524–2530.

K. Verbeken, E. Gomes, J. Schneider and Y. Houbaert, Correlation Between the Magnetic Properties and the Crystallographic Texture During the Processing of Non Oriented Electrical Steel, Solid State Phenom., 2010, 160, p 189–194.

A Martinez-de-Guerenu, F Arizti, I Gutiérrez, , Recovery during annealing in a cold rolled low carbon steel. Part II: Modelling the kinetics, Acta Mater., 2004, 52(12), p 3665–3670.

Acknowledgments

The authors are thankful to Director, VNIT Nagpur for providing the necessary facilities and constant encouragement to publish this paper. The authors would like to acknowledge the use of National Facility for Texture and OIM (A DST-IRPHA project), IIT, Bombay for EBSD, and bulk texture measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dandekar, T.R., Kumar, A., Khatirkar, R.K. et al. Multistep Cross Rolling of UNS S32101 Steel: Microstructure, Texture, and Magnetic Properties. J. of Materi Eng and Perform 30, 2916–2929 (2021). https://doi.org/10.1007/s11665-021-05510-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05510-z