Abstract

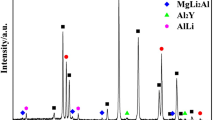

In this study, Mg-3Al-1Sn-1Nd-Mn alloy was produced by low-pressure die casting method and homogenization heat treated (HHT) at 400 °C for 16 hrs. Microstructural characterization of the alloy was done by XRF, XRD, LOM and SEM–EDS analyses. The microstructure of the alloy was composed of α-Mg, Al2Nd and Al11Nd3 phases. Hot rolling was applied to the HHT alloy at two different speeds 13.78 rpm [low speed rolling (LSR)] and 26.96 rpm [high-speed rolling (HSR)] at 350 °C. Microstructural changes were also carried out by LOM and SEM analyses. Mechanical properties (hardness and tensile properties) and wear performances of HHT, LSR and HSR samples were compared. SEM fractography was conducted on tension test samples to visualize the deformation and fracture behaviors. Also, worn surfaces of samples were investigated by SEM–EDS analysis. Abrasive, oxidation and delamination mechanisms were observed for worn surfaces of samples. To sum up, the mechanical properties of the HSR sample were higher compared to the HHT and LSR samples, and the wear rate was lower than HHT and LSR samples.

Similar content being viewed by others

References

J. Song, J. She, D. Chen, and F. Pan, Latest Research Advances on Magnesium and Magnesium Alloys Worldwide, J. Magnes. Alloys, 2020, 8(1), p 1–41.

D.S. Kumar, C.T. Sasanka, K. Ravindra and K.N.S. Suman, Magnesium and Its Alloys in Automotive Applications—A Review, Am. J. Mater. Sci. Technol., 2015, 4(1), p 12–30.

A. Jena, N. Naskar, N. Kumar, and M. Paliwal, Investigation of As-Cast and Homogenized Microstructure in Mg-6 Wt% Sn-1 Wt% Al Alloy: An Experimental and Modelling Study, Met. Mater. Int., 2020. https://doi.org/10.1007/s12540-020-00718-5.

C.-Y. Zhao, X.-H. Chen, P. Peng, T. Tu, A. Atrens and F.-S. Pan, Microstructures and Mechanical Properties of Mg-x Al-1Sn-0.3 Mn (X= 1, 3, 5) Alloy Sheets, Acta Metall. Sin. Engl. Lett., 2020, 33, p 1–9.

J. She, F. Pan, J. Zhang, A. Tang, S. Luo, Z. Yu, K. Song and M. Rashad, Microstructure and Mechanical Properties of Mg-Al-Sn Extruded Alloys, J. Alloys Compd., 2016, 657, p 893–905.

X. Liu, D. Shan, Y. Song, R. Chen and E. Han, Influences of the Quantity of Mg2Sn Phase on the Corrosion Behavior of Mg-7Sn Magnesium Alloy, Electrochim. Acta, 2011, 56(5), p 2582–2590.

H.-Y. Wang, N. Zhang, C. Wang and Q.-C. Jiang, First-Principles Study of the Generalized Stacking Fault Energy in Mg-3Al-3Sn Alloy, Scr. Mater., 2011, 65(8), p 723–726.

D. Luo, H.-Y. Wang, L. Zhang, G.-J. Liu, J.-B. Li and Q.-C. Jiang, Microstructure Evolution and Tensile Properties of Hot Rolled Mg–6Al–3Sn Alloy Sheet at Elevated Temperatures, Mater. Sci. Eng. A, 2015, 643, p 149–155.

S.Q. Zhu and S.P. Ringer, On the Role of Twinning and Stacking Faults on the Crystal Plasticity and Grain Refinement in Magnesium Alloys, Acta Mater., 2018, 144, p 365–375.

F.-W. Bach, M. Rodman, A. Rossberg, B.-A. Behrens and G. Kurzare, Macroscopic Damage by the Formation of Shear Bands during the Rolling and Deep Drawing of Magnesium Sheets, JOM, 2005, 57(5), p 57–61.

A.S.H. Kabir, M. Sanjari, J. Su, I.-H. Jung and S. Yue, Effect of Strain-Induced Precipitation on Dynamic Recrystallization in Mg-Al-Sn Alloys, Mater. Sci. Eng. A, 2014, 616, p 252–259.

B.-C. Suh, J.H. Kim, J.H. Bae, J.H. Hwang, M.-S. Shim and N.J. Kim, Effect of Sn Addition on the Microstructure and Deformation Behavior of Mg-3Al Alloy, Acta Mater., 2017, 124, p 268–279.

L. Wen, P. Chen, Z.-F. Tong, B.-Y. Tang, L.-M. Peng and W.-J. Ding, A Systematic Investigation of Stacking Faults in Magnesium Via First-Principles Calculation, Eur. Phys. J. B, 2009, 72(3), p 397.

K.M. Asl, Improving the Properties of Magnesium Alloys for High Temperature Applications, Magnesium Alloys: Design, Processing and Properties, vol. 1, F. Czerwinski, Ed., Intech Open, 2011, p 265–280

J. Wang, L. Wang, J. An and Y. Liu, Microstructure and Elevated Temperature Properties of Die-Cast AZ91-XNd Magnesium Alloys, J. Mater. Eng. Perform., 2008, 17(5), p 725–729.

S. Polat, Y. Sun, E. Çevik, H. Colijn and M.E. Turan, Investigation of Wear and Corrosion Behavior of Graphene Nanoplatelet-Coated B4C Reinforced Al-Si Matrix Semi-Ceramic Hybrid Composites, J. Compos. Mater., 2019, 53(25), p 3549–3565.

J. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24(8), p 981–988.

J. Wang, J. Fu, X. Dong and Y. Yang, Microstructure and Mechanical Properties of As-Cast Mg-Al-Sn-Y-Nd Alloy, Mater. Des. 1980-2015, 2012, 36, p 432–437.

H. Simsir, Y. Akgul and M.A. Erden, Hydrothermal Carbon Effect on Iron Matrix Composites Produced by Powder Metallurgy, Mater. Chem. Phys., 2020, 242, p 122557.

D. Tian, H. Yan, J. Chen, W. Xia, S.U. Bin and Z. Yu, Dynamic Recrystallization and Mechanical Properties of High-Strain-Rate Hot Rolled Mg-5Zn Alloys with Addition of Ca and Sr, Trans. Nonferrous Met. Soc. China, 2019, 29(8), p 1631–1640.

D.L. Yin, K.F. Zhang, G.F. Wang and W.B. Han, Warm Deformation Behavior of Hot-Rolled AZ31 Mg Alloy, Mater. Sci. Eng. A, 2005, 392(1–2), p 320–325.

F. Guo, D. Zhang, X. Yang, L. Jiang, S. Chai and F. Pan, Effect of Rolling Speed on Microstructure and Mechanical Properties of AZ31 Mg Alloys Rolled with a Wide Thickness Reduction Range, Mater. Sci. Eng. A, 2014, 619, p 66–72.

J. Kubásek, D. Vojtěch, J. Lipov and T. Ruml, Structure, Mechanical Properties, Corrosion Behavior and Cytotoxicity of Biodegradable Mg–X (X= Sn, Ga, In) Alloys, Mater. Sci. Eng. C, 2013, 33(4), p 2421–2432.

Q.-C. Le, Z. Zhang, Z. Shao, J. Cui and X.I.E. Yi, Microstructures and Mechanical Properties of Mg-2% Zn-0.4% RE Alloys, Trans. Nonferrous Met. Soc. China, 2010, 20, p s352–s356.

G. Liu, J. Zhang and Y. Dou, First-Principles Study of Solute–Solute Binding in Magnesium Alloys, Comput. Mater. Sci., 2015, 103, p 97–104.

M. Laurent-Brocq, A. Akhatova, L. Perrière, S. Chebini, X. Sauvage, E. Leroy and Y. Champion, Insights into the Phase Diagram of the CrMnFeCoNi High Entropy Alloy, Acta Mater., 2015, 88, p 355–365.

T.J. Chen, R.Q. Wang, Y. Ma and Y. Hao, Grain Refinement of AZ91D Magnesium Alloy by Al-Ti-B Master Alloy and Its Effect on Mechanical Properties, Mater. Des., 2012, 34, p 637–648.

A.N. Chamos, S.G. Pantelakis, G.N. Haidemenopoulos and E. Kamoutsi, Tensile and Fatigue Behaviour of Wrought Magnesium Alloys AZ31 and AZ61, Fatigue Fract. Eng. Mater. Struct., 2008, 31(9), p 812–821.

J. Wang and L.L. Shaw, Grain-Size Dependence of the Hardness of Submicrometer and Nanometer Hydroxyapatite, J. Am. Ceram. Soc., 2010, 93(3), p 601–604.

S. You, Y. Huang, K.U. Kainer and N. Hort, Recent Research and Developments on Wrought Magnesium Alloys, J. Magnes. Alloys, 2017, 5(3), p 239–253.

H. Yu, Y. Xin, M. Wang and Q. Liu, Hall-Petch Relationship in Mg Alloys: A Review, J. Mater. Sci. Technol., 2018, 34(2), p 248–256.

N.A. Latif, Z. Sajuri, J. Syarif, and Y. Mutoh, Effect of Strain Rate on Tensile Strength and Work Hardening for Al-Zn Magnesium Alloys, Recent Trends in Nanotechnology and Materials Science, vol. 1, F. Gaol, J. Webb, Ed., Springer, 2014, p 77–91

B. Pourbahari, M. Emamy and H. Mirzadeh, Synergistic Effect of Al and Gd on Enhancement of Mechanical Properties of Magnesium Alloys, Prog. Nat. Sci. Mater. Int., 2017, 27(2), p 228–235.

V.V. Ramalingam, P. Ramasamy, M.D. Kovukkal, and G. Myilsamy, Research and Development in Magnesium Alloys for Industrial and Biomedical Applications: A Review, Met. Mater. Int., 2020, 26, p 409–430.

M. Srinivasan, C. Loganathan, M. Kamaraj, Q.B. Nguyen, M. Gupta and R. Narayanasamy, Sliding Wear Behaviour of AZ31B Magnesium Alloy and Nano-Composite, Trans. Nonferrous Met. Soc. China, 2012, 22(1), p 60–65.

J. An, R.G. Li, Y. Lu, C.M. Chen, Y. Xu, X. Chen and L.M. Wang, Dry Sliding Wear Behavior of Magnesium Alloys, Wear, 2008, 265(1–2), p 97–104.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kara, I.H., Incesu, A. Microstructural, Mechanical, and Tribological Properties of Mg-3Al-1Sn-1Nd-Mn Alloy. J. of Materi Eng and Perform 30, 1674–1682 (2021). https://doi.org/10.1007/s11665-021-05463-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05463-3