Abstract

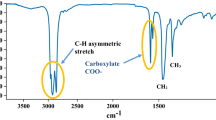

In the current study, the tribological performance of two different synthetic lubricants, i.e., polyalphaolefin (PAO 100) and polypropylene glycol (PPG 2000), were analyzed. The COOH-functionalized multiwalled carbon nanotubes (MWCNTs) were used as an additive in varying fractions (0.025-0.15 wt.%). The friction and wear studies were carried out as per ASTM D6425 by using SRV 5 tribometer with a ‘ball on disk’ configuration. The results showed that tribological performance gets enhanced remarkably with the inclusion of MWCNTs in both lubricants as compared to the pure lubricants. PAO 100 demonstrated the lowest coefficient of friction and wear volume at a concentration of 0.025 and 0.05 wt.% of MWCNTs, respectively. However, 0.025 wt.% of additive in PPG 2000 exhibited the maximum reduction in the coefficient of friction (~6%) and wear volume (~86%). The results confirmed that PAO 100 showed better tribological performance as compared to PPG 2000. The lubrication mechanism of MWCNTs has been demonstrated through the investigation of worn steel ball surfaces by using various characterization techniques such as scanning electron microscope, energy-dispersive x-ray spectroscopy (EDS) and scan probe microscope.

Similar content being viewed by others

References

S. Iijima, Helical Microtubules of Graphitic Carbon, Nature, 1991, 354, p 56–58.

S. Mallakpour and S. Soltanian, Surface Functionalization of Carbon Nanotubes: Fabrication and Applications, RSC Adv., Royal Society of Chemistry, 2016, 6(111), p 109916–109935.

S. Shahnazar, S. Bagheri, and S.B. Abd Hamid, Enhancing Lubricant Properties by Nanoparticle Additives, Int. J. Hydrogen Energy, Elsevier Ltd, 2016, 41(4), p 3153–3170.

J.H. Lehman, M. Terrones, E. Mansfield, K.E. Hurst, and V. Meunier, Evaluating the Characteristics of Multiwall Carbon Nanotubes, Carbon N. Y., Elsevier Ltd, 2011, 49(8), p 2581–2602.

Y. Peng and Z. Ni, Tribological Properties of Stearic Acid Modified Multi-Walled Carbon Nanotubes in Water, J. Tribol., 2013, 135(1), p 1–5.

D. Tasis, N. Tagmatarchis, A. Bianco and M. Prato, Chemistry of Carbon Nanotubes, Chem. Rev., 2006, 106(3), p 1105–1136.

X. Pei, L. Hu, W. Liu and J. Hao, Synthesis of Water-Soluble Carbon Nanotubes via Surface Initiated Redox Polymerization and Their Tribological Properties as Water-Based Lubricant Additive, Eur. Polym. J., 2008, 44(8), p 2458–2464.

C.S. Chen, X.H. Chen, L.S. Xu, Z. Yang and W.H. Li, Modification of Multi-Walled Carbon Nanotubes with Fatty Acid and Their Tribological Properties as Lubricant Additive, Carbon N. Y., 2005, 43(8), p 1660–1666.

F.H. Gojny, J. Nastalczyk, Z. Roslaniec and K. Schulte, Surface Modified Multi-Walled Carbon Nanotubes in CNT/Epoxy-Composites, Chem. Phys. Lett., 2003, 370(5-6), p 820–824.

Y. Choi, J. and Zhang, “Single , Double , MultiWall Carbon Nanotube Properties & Applications,” Aldrich Materials Science, Sigma-Aldrich Co. LLC., 2018.

W. Khalil, A. Mohamed, M. Bayoumi and T.A. Osman, Tribological Properties of Dispersed Carbon Nanotubes in Lubricant, Fullerenes Nanotub. Carbon Nanostructures, 2016, 24(7), p 479–485.

S.M. Muzakkir, K.P. Lijesh and H. Hirani, Influence of Surfactants on Tribological Behaviors of MWCNTs (Multi-Walled Carbon Nano-Tubes), Tribol. - Mater. Surfaces Interfaces, 2016, 10(2), p 74–81.

V. Chauveau, D. Mazuyer, F. Dassenoy and J. Cayer-Barrioz, In Situ Film-Forming and Friction-Reduction Mechanisms for Carbon-Nanotube Dispersions in Lubrication, Tribol. Lett., 2012, 47(3), p 467–480.

B. Wang, W. Tang, X. Liu, and Z. Huang, Synthesis of Ionic Liquid Decorated Muti-Walled Carbon Nanotubes as the Favorable Water-Based Lubricant Additives, Appl. Phys. A Mater. Sci. Process., Springer Berlin Heidelberg, 2017, 123(11), p 680.

B. Yu, Z. Liu, C. Ma, J. Sun, W. Liu and F. Zhou, Ionic Liquid Modified Multi-Walled Carbon Nanotubes as Lubricant Additive, Tribol. Int., 2015, 81(January), p 38–42.

B. Yu, Z. Liu, F. Zhou, W. Liu and Y. Liang, A Novel Lubricant Additive Based on Carbon Nanotubes for Ionic Liquids, Mater. Lett., 2008, 62(17-18), p 2967–2969.

Y. Peng, Y. Hu and H. Wang, Tribological Behaviors of Surfactant-Functionalized Carbon Nanotubes as Lubricant Additive in Water, Tribol. Lett., 2007, 25(3), p 247–253.

R. Benda, J. Bullen and A. Plomer, Synthetic Basics: Polyalphaolefins - Base Fluids for High-Performance Lubricants, J. Synth. Lubr., 1996, 13(1), p 40–57.

L.R. Rudnick, in Synthetics, Mineral Oils, and Bio-Based Lubricants: Chemistry and Technology,”, L.R. Rudnick, Ed., (New York, NY), CRC Press, 2005.

G. Yang, J. Zhang, S. Zhang, L. Yu, P. Zhang, and B. Zhu, Preparation of Triazine Derivatives and Evaluation of Their Tribological Properties as Lubricant Additives in Poly-Alpha Olefin, Tribol. Int., Elsevier, 2013, 62, p 163–170.

R. Chou, A.H. Battez, J.J. Cabello, J.L. Viesca, A. Osorio and A. Sagastume, Tribological Behavior of Polyalphaolefin with the Addition of Nickel Nanoparticles, Tribol. Int., 2010, 43(12), p 2327–2332.

S. Paskvale, M. Remškar and M. Čekada, Tribological Performance of TiN, TiAlN and CrN Hard Coatings Lubricated by MoS2 Nanotubes in Polyalphaolefin Oil, Wear, 2016, 352-353, p 72–78.

N.G. Demas, E. V. Timofeeva, J.L. Routbort, and G.R. Fenske, Tribological Effects of BN and MoS2 Nanoparticles Added to Polyalphaolefin Oil in Piston Skirt/Cylinder Liner Tests, Tribol. Lett., American Society of Mechanical Engineers, 2012, 47(1), p 91–102.

S.M. Alves, V.S. Mello, E.A. Faria, and A.P.P. Camargo, Nanolubricants Developed from Tiny CuO Nanoparticles, Tribol. Int., Elsevier, 2016, 100, p 263–271.

M. Zhang, X. Wang, X. Fu and Y. Xia, Performance and Anti-Wear Mechanism of CaCO3 Nanoparticles as a Green Additive in Poly-Alpha-Olefin, Tribol. Int., 2009, 42(7), p 1029–1039.

J.L. Viesca, A. Hernández Battez, R. González, R. Chou, and J.J. Cabello, Antiwear Properties of Carbon-Coated Copper Nanoparticles Used as an Additive to a Polyalphaolefin, Tribol. Int., 2011, 44(7-8), p 829–833.

M. Zhang, X. Wang and W. Liu, Tribological Behavior of LaF3 Nanoparticles as Additives in Poly-alpha-olefin, Ind. Lubr. Tribol., 2013, 65(4), p 226–235.

T. Zolper, Z. Li, C. Chen, M. Jungk, T. Marks, Y.-W. Chung and Q. Wang, Lubrication Properties of Polyalphaolefin and Polysiloxane Lubricants: Molecular Structure-Tribology Relationships, Tribol. Lett., 2012, 48(3), p 355–365.

K. Li, X. Zhang, C. Du, J. Yang, B. Wu, Z. Guo, C. Dong, N. Lin and C. Yuan, Friction Reduction and Viscosity Modification of Cellulose Nanocrystals as Biolubricant Additives in Polyalphaolefin Oil, Carbohydr. Polym., 2019, 220, p 228–235.

W. Yue, X. Sun, C. Wang, Z. Fu, Y. Liu, and J. Liu, A Comparative Study on the Tribological Behaviors of Nitrided and Sulfur-Nitrided 35CrMo Steel Lubricated in PAO Base Oil with MoDTC Additive, Tribol. Int., Elsevier, 2011, 44(12), p 2029–2034.

J. Kogovšek and M. Kalin, Various MoS2-, WS2- and C-Based Micro- and Nanoparticles in Boundary Lubrication, Tribol. Lett., 2014, 53(3), p 585–597.

N. Nunn, Z. Mahbooba, M.G. Ivanov, D.M. Ivanov, D.W. Brenner and O. Shenderova, Tribological Properties of Polyalphaolefin Oil Modified with Nanocarbon Additives, Diam. Relat. Mater., 2015, 54(April), p 97–102.

D. Beatty and M. Greaves, Polyalkylene Glycol Synthetic PAG Oil Explained, Mach. Lubr. Mag., 2006, 9(September), p 1–7, https://www.machinerylubrication.com/Read/930/pag-synthetic-oil.

The Dow Chemical Company, “Product Safety Assessment Polyglycol P Series Polymers, FLUENT Brand Polyglycol,” The Dow Chemical Company, 2014, p 1–6.

M.R. Greaves, Polyalkylene Glycols: Present and Future Applications, Tribol. Lubr. Technol., 2013, 69(6), p 34–39.

S. Igari, S. Mori and Y. Takikawa, Effects of Molecular Structure of Aliphatic Diols and Polyalkylene Glycol as Lubricants on the Wear of Aluminum, Wear, 2000, 244(1-2), p 180–184.

H. Xiao, S. Liu, Y. Chen, D. Han, and D. Wang, Impacts of Polypropylene Glycol (PPG) Additive and PH on Tribological Properties of Water-Based Drilling Mud for Steel-Steel Contact, Tribol. Int., Elsevier Ltd, 2017, 110(February), p 318–325.

C. Zhang, J. Liu, C. Zhang and S. Liu, Friction Reducing and Anti-Wear Property of Metallic Friction Pairs under Lubrication of Aqueous Solutions with Polyether Added, Wear, Elsevier, 2012, 292-293, p 11–16.

D. Klaffke, Fretting Wear of Ceramics, Tribol. Int., 1989, 22(2), p 89–101.

D. Hamrock, B.J. and Dowson, “Minimum Film Thickness in Elliptical Contacts for Different Regimes of Fluid-Film Lubrication,” NASA Technical Paper-1342, (Cleveland, Ohio), 1978.

W.R. Jones, R.L. Johnson, W.O. Winer, and D.M. Sanborn, Pressure-Viscosity Measurements for Several Lubricants to 5.5 × 10^8 Newtons Per Square Meter (8 × 10^4 PSI) and 149 C (300 F), A S L E Trans., 1975, 18(4), p 249–262.

B.J. Hamrock, Schmid S. R., and B.O. Jacobson, Fundamental of Fluid Film Lubrication, Marcel Dekker, Inc., New York, 2004.

V.T. Le, C.L. Ngo, Q.T. Le, T.T. Ngo, D.N. Nguyen, and M.T. Vu, Surface Modification and Functionalization of Carbon Nanotube with Some Organic Compounds, Adv. Nat. Sci. Nanosci. Nanotechnol., 2013, 4(3), p 035017.

N.M. Vesali, A.A. Khodadadi, Y. Mortazavi, A.O. Sahraei, F. Pourfayaz and M.S. Sedghi, Functionalization of Carbon Nanotubes Using Nitric Acid Oxidation and DBD Plasma, World Acad. Sci. Eng. Technol., 2009, 37(January), p 177–179.

V.M. Rao, C.H. Castano, J. Rojas, and A.J. Abdulghani, Synthesis of Nickel Nanoparticles on Multi-Walled Carbon Nanotubes by Gamma Irradiation, Radiat. Phys. Chem., Elsevier, 2013, 89(August), p 51–56.

H. Kumar and A.P. Harsha, Investigation on Friction, Anti-Wear, and Extreme Pressure Properties of Different Grades of Polyalphaolefins With Functionalized Multi-Walled Carbon Nanotubes as an Additive, J. Tribol., 2020, 142(8), p 1702–1714.

M.Y. Cheah, H.C. Ong, N.W.M. Zulkifli, H.H. Masjuki, and A. Salleh, Physicochemical and Tribological Properties of Microalgae Oil as Biolubricant for Hydrogen-Powered Engine, Int. J. Hydrogen Energy, Elsevier Ltd, 2020, 45(42), p 22364–22381.

R. Wäsche, M. Hartelt, and V.-D. Hodoroaba, Analysis of Nanoscale Wear Particles from Lubricated Steel–Steel Contacts, Tribol. Lett., 2015, 58(3), p 49.

L. Hongtao, J. Hongmin, H. Haiping and H. Younes, Tribological Properties of Carbon Nanotube Grease, Ind. Lubr. Tribol., 2014, 66(5), p 579–583.

J.A.C. Cornelio, P.A. Cuervo, L.M. Hoyos-Palacio, J. Lara-Romero, and A. Toro, Tribological Properties of Carbon Nanotubes as Lubricant Additive in Oil and Water for a Wheel–Rail System, J. Mater. Res. Technol., Korea Institute of Oriental Medicine, 2016, 5(1), p 68–76.

L. Zhang, J. Pu, L. Wang and Q. Xue, Synergistic Effect of Hybrid Carbon Nanotube-Graphene Oxide as Nanoadditive Enhancing the Frictional Properties of Ionic Liquids in High Vacuum, ACS Appl. Mater. Interfaces, 2015, 7(16), p 8592–8600.

L. Zhang, J. Pu, L. Wang, and Q. Xue, Frictional Dependence of Graphene and Carbon Nanotube in Diamond-like Carbon/Ionic Liquids Hybrid Films in Vacuum, Carbon N. Y., Elsevier Ltd, 2014, 80(1), p 734–745.

Acknowledgments

The authors are thankful to the Central Instrument Facility (CIF), IIT (BHU) for the characterization of the samples. One of the authors (A.P. Harsha) would like to thank the staff of the fretting wear group, 6.3 Division of Macro Tribology and Wear Protection, Federal Institute for Materials Research and Testing (BAM), Berlin, Germany, for their support during the experimental studies. We also thank BAM for providing financial support for the duration of this research during the stay for the work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, H., Harsha, A.P. Enhanced Lubrication Ability of Polyalphaolefin and Polypropylene Glycol by COOH-Functionalized Multiwalled Carbon Nanotubes as an Additive. J. of Materi Eng and Perform 30, 1075–1089 (2021). https://doi.org/10.1007/s11665-020-05450-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05450-0