Abstract

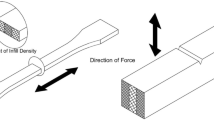

This paper studies the influence of factors such as printing speed, layer height, infill density, and type of material, over the mechanical properties of 3D printed pieces. A statistical analysis was conducted in order to determine the effect of each factor over the impact resistance of the 3D printed specimens. Samples of polycarbonate (PC) and nylon + carbon fiber (PA + CF) were tested using conventional Charpy equipment. Initially, the design of experiments was used to evaluate the significance of the studied factors, then, a sequential design was carried out to determine the process parameters that result in the maximum absorption of energy on the material. Finally, the results showed that during the selection phase, the type of material was the factor with the most significant effect, with a 99.5% of importance which is affected by the layer height and infill density. It was found that the absorbed energy was higher for the material PA + CF, according to the statistical results obtained.

Similar content being viewed by others

References

M. Harris, J. Potgieter, R. Archer and K.M. Arif, Effect of Material and Process Specific Factors on the Strength of Printed Parts in Fused Filament Fabrication: A Review of Recent Developments, Materials (Basel), 2019, 12(1664), p 1–35.

Q. Zhang and C. Li, The Roles of Traditional Chinese Medicine: Shen-Fu Injection on the Postresuscitation Care Bundle, Evid. Based Complement. Altern., 2013, 1(319092), p 1–7.

C.R. Garcia et al., Effects of Extreme Surface Roughness on 3D Printed Horn Antenna, Electron. Lett., 2013, 49(12), p 734.

B. Berman, F.G. Zarb and W. Hall, 3-D Printing: The New Industrial Revolution, Bus. Horiz., 2012, 55(2), p 155–162.

S.-H. Ahn, K.-T. Lee, H.-J. Kim, R. Wu, J.-S. Kim and S.-H. Song, Smart Soft Composite: An Integrated 3D Soft Morphing Structure Using Bend-twist Coupling of Anisotropic Materials, Int. J. Precis. Eng. Manuf., 2012, 13(4), p 631–634.

N.A. Ahmed and J.R. Page, Manufacture of an Unmanned Aerial Vehicle (UAV) for Advanced Project Design Using 3D Printing Technology, Appl. Mech. Mater., 2013, 397–400(1), p 970–980.

S.-S. Yao, F.-L. Jin, K.Y. Rhee, D. Hui and S.-J. Park, Recent Advances in Carbon-Fiber-Reinforced Thermoplastic Composites: A Review, Compos. Part B Eng., 2018, 142, p 241–250.

L.G. Blok, M.L. Longana, H. Yu and B.K.S. Woods, An Investigation into 3D Printing of Fibre Reinforced Thermoplastic Composites, Addit. Manuf., 2018, 22(1), p 176–186.

J.L. Walker and M. Santoro, Processing and Production of Bioresorbable Polymer Scaffolds for Tissue Engineering, Elsevier, Amsterdam, 2017.

J. Cantrell et al., Experimental Characterization of the Mechanical Properties of 3D-Printed ABS and Polycarbonate Parts. p 1–19, 2017.

C.O. Balderrama-Armendariz, E. MacDonald, D. Espalin, D. Cortes-Saenz, R. Wicker and A. Maldonado-Macias, Torsion Analysis of the Anisotropic Behavior of FDM Technology, Int. J. Adv. Manuf. Technol., 2018, 96(1), p 307–317.

J.R.C. Dizon, A.H. Espera, Q. Chen and R.C. Advincula, Mechanical Characterization of 3D-Printed Polymers, Addit. Manuf., 2018, 20, p 44–67.

M.Á. Caminero, J.M. Chacón, E. García-Plaza, P.J. Núñez, J.M. Reverte and J.P. Becar, Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture, Polymers (Basel), 2019, 11(5), p 799.

S. Hamid and R. Sanei, 3D-Printed Carbon Fiber Reinforced Polymer Composites: A Systematic Review, J. Compos. Sci., 2020, 4(98), p 1–23.

Y. Ortega, Prueba de Impacto: Ensayo Charpy, Rev. Mex. Fis., 2006, 52(1 SUPPL.), p 51–57.

A.E. Matusevich, R.A. Mancini and A.J. Giudici, Determinación de la Tenacidad a la Fractura del Material de un Gasoducto, Rev. Latinoam. Metal. Mater., 2012, 32(2), p 253–260.

T. Webbe Kerekes, H. Lim, W.Y. Joe and G.J. Yun, Characterization of Process–Deformation/Damage Property Relationship of Fused Deposition Modeling (FDM) 3D-Printed Specimens, Addit. Manuf., 2019, 25, p 532–544.

M. Dawoud, I. Taha and S.J. Ebeid, Mechanical Behaviour of ABS: An Experimental Study Using FDM and Injection Moulding Techniques, J. Manuf. Process., 2016, 21, p 39–45.

M.A. Caminero, J.M. Chacón, I. García-Moreno and G.P. Rodríguez, Impact Damage Resistance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling, Compos. Part B Eng., 2018, 148(April), p 93–103.

F. Van Der Klift, Y. Koga, A. Todoroki, M. Ueda and Y. Hirano, 3D Printing of Continuous Carbon Fibre Reinforced Thermo-Plastic (CFRTP) Tensile Test Specimens, Open J. Compos. Mater., 2016, 6, p 18–27.

M. Caminero, J. Chacón, E. García-Plaza, P. Núñez, J. Reverte and J. Becar, Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture, Polymers (Basel), 2019, 11(799), p 1–22.

A. Kantaros and D. Karalekas, Fiber Bragg Grating Based Investigation of Residual Strains in ABS Parts Fabricated by Fused Deposition Modeling Process, Mater. Des., 2013, 50, p 44–50.

R. Singh, S. Singh and F. Fraternali, Development of In-house Composite Wire Based Feed Stock Filaments of Fused Deposition Modelling for Wear-Resistant Materials and Structures, Compos. Part B, 2016, 98, p 244–249.

H. De Vries, R. Engelen and E. Janssen, Impact Strength 3D-Printed Polycarbonate, Electron. Energy, 2020, 33(1), p 105–117.

A.E. Patterson, T.R. Pereira, J.T. Allison and S.L. Messimer, IZOD Impact Properties of Full-density Fused Deposition Modeling Polymer Materials with Respect to Raster Angle and Print Orientation, Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci., 2019, 1, p 1–18.

L.G. Blok, M.L. Longana, H. Yu and B.K.S. Woods, An Investigation into 3D Printing of Fibre Reinforced Thermoplastic Composites, Addit. Manuf., 2018, 22, p 176–186.

C. Benwood, A. Anstey, J. Andrzejewski, M. Misra and A.K. Mohanty, Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlationships during Fused Deposition Modeling (FDM) of Poly(Lactic Acid), ACS Omega, 2018, 3(4), p 4400–4411.

Specialchem, Omnexus. The material selection platform. WebPage, 2020. https://omnexus.specialchem.com/selection-guide/polycarbonate-pc-plastic.

H. Gutiérrez Pulido and R. De La Vara Salazar, Análisis y Diseño de Experimentos, Vol 1 McGraw-Hil, Mexico, 2015.

D.A. Roberson, A.R. Torrado Perez, C.M. Shemelya, A. Rivera, E. MacDonald and R.B. Wicker, Comparison of Stress Concentrator Fabrication for 3D Printed Polymeric Izod Impact Test Specimens, Addit. Manuf., 2015, 7, p 1–11.

A. Tsouknidas, M. Pantazopoulos, I. Katsoulis, D. Fasnakis, S. Maropoulos and N. Michailidis, Impact Absorption Capacity of 3D-Printed Components Fabricated by Fused Deposition Modelling, Mater. Des., 2016, 102, p 41–44.

G. Liao et al., Properties of Oriented Carbon Fiber/Polyamide 12 Composite Parts Fabricated by Fused Deposition Modeling, Mater. Des., 2018, 139, p 283–292.

L. Wang and D.J. Gardner, Contribution of Printing Parameters to the Interfacial Strength of Polylactic Acid (PLA) in Material Extrusion Additive Manufacturing, Prog. Addit. Manuf., 2018, 3(3), p 165–171.

E. Yasa, “Anisotropic Impact Toughness of Chopped Carbon Fiber Reinforced Nylon Fabricated By Material-Extrusion-Based Additive Manufacturing, Anadolu Univ J. Sci. Technol. Appl. Sci. Eng., 2019, 20(2), p 195–203.

R. St, G. Lebrun and F. Brouillette, Effect of Compaction Parameters on Preform Permeability and Mechanical Properties of Unidirectional Flax Fiber Composites, Compos. Part B, 2019, 176(107083), p 1–10.

R. García-León, B. Argotta-Isidro and W. Quintero-Quintero, Diseño de Una Máquina de Termoconformados Para la Fabricaciónde Filamento ABS Y PLA, Informador Técnico, 2020, 85(1), p 34–51.

Acknowledgments

This work was supported by the Universidad Francisco de Paula Santander Ocaña, Colombia 158-08-026 Research Grant. We thank E. Perez for his comments on statistical analysis and Celee for editing and reviewing the draft of this manuscript.

Author information

Authors and Affiliations

Contributions

R.A.G.-L put forward the experimental idea and designed, performed the experiments, drafted, and revised the manuscript; M.R.-C and W.Q.-Q performed the data and statistical analysis.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

About this article

Cite this article

García-León, R.A., Rodríguez-Castilla, M. & Quintero-Quintero, W. Experimental Analysis of Impact Resistance of 3D Polycarbonate and Nylon + Carbon Fiber Specimens. J. of Materi Eng and Perform 30, 4837–4847 (2021). https://doi.org/10.1007/s11665-020-05422-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05422-4