Abstract

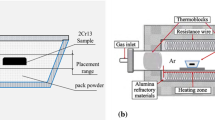

In this study, the tribological performance of two FeB/Fe2B systems formed at the surface of an AISI 316L stainless steel was evaluated experimentally as well as numerically using the configuration rotatory pin-on-disk test, without lubricant and using a ball as a counterpart. The wear tests were carried out along a circular path under two applied loads of 5 and 10 N and a constant sliding distance. The wear coefficient was obtained by Archard’s model. Experimental results of the wear test exhibited that the FeB/Fe2B system with the thinner thickness developed more severe wear. The principal stresses and the maximum shear stress at the beginning and at the end of the pin-on-disk test were assessed by means of the finite element method. Mesh nonlinear adaptivity was used in the numerical model of the pin-on-disk test to fix mesh distortion caused by the surface wear. As the pin-on-disk test progressed and the material was removed, it caused a non-uniform contact pressure on the contact zone, which generated high stress at small areas of boride layers.

Similar content being viewed by others

References

G. Schuhler, A. Jourani, S. Bouvier, and J.M. Perrochat, Efficacy of Coatings and Thermochemical Treatment to Improve Wear Resistance of Axial Piston Pumps, Tribol. Int., 2018, 126, p 376–385

B. Suh and W. Lee, Surface Hardening of AISI, 316L Stainless Steel Using Plasma Carburizing, Thin Solid Films, 1997, 295, p 185–192

V. Singh, K. Marchev, C. Cooper, and E. Meletis, Intensified Plasma-Assisted Nitriding of AISI, 316L Stainless Steel, Surf. Coat. Technol., 2002, 160, p 249–258

A.P. Krelling, C.E. da Costa, J.C.G. Milan, and E.A.S. Almeida, Micro-abrasive Wear Mechanisms of Borided AISI, 1020 Steel, Tribol. Int., 2017, 111, p 234–242

J. Lubas, Practical Application of Boron-Modified Sliding Pairs in I.C. Engine, Tribol. Int., 2010, 43, p 2046–2050

V. Peretti, S. Ferraris, G. Gautier, C. Hellmich, O. Lahayne, B. Stella, S. Yamaguchi, and S. Spriano, Surface Treatment for Boriding of Ti6Al14V Alloy in View of Applications as a Biomaterial, Tribol. Int., 2018, 126, p 21–28

I. Gutierres-Noda, C.A. Cuau-Moreu, O. Perez-Acosta, E. Lorenzo-Bonet, P. Zambrano-Robledo, and M.A.I. Hernandez-Rodriguez, The Effect of a Boride Diffusion Layer on the Tribological Properties of AISI, M2 Steel, Wear, 2019, 426, p 1667–1671

I. Ozbek, B. Konduk, C. Bindal, and A. Ucisik, Characterization of Borided AISI, 316L Stainless Steel Implant, Vacuum, 2002, 65, p 521–525

G. Kartal, A. Bora, and S. Timur, Evaluating the Mechanical Behavior of Electrochemically Borided Low-Carbon Steel, Surf. Coat. Technol., 2020, 381, p 1–10

A. Graf von Matuschka, Boronizing, Carl Hanser Verlag, Munich, 1980

I. Campos, A.D. Contla, U. Figueroa, J. Martínez, A. Garduño, and M. Ortega, Sliding Wear Resistance of Nickel Boride Layers on an Inconel 718 Superalloy, Surf. Coat. Technol., 2019, 378, p 1–13

M. Keddam and S.M. Chentouf, A Diffusion Model for Describing the Bilayer Growth (FeB/Fe2B) during the Iron Powder-Pack Boriding, Appl. Surf. Sci., 2005, 252, p 393–399

F. Ficici, M. Kapsiz, and M. Durant, Applications of Taguchi Design Method to Study Wear Behaviour of Boronized AISI, 1040 Steel, Int. J. Phys. Sci., 2011, 6, p 237–243

I. Turkmen, E. Yalamac, and M. Keddam, Investigation of Triboligical Behavior and Diffusion Model of Fe2B Formed by Pack-Boriding on SAE 1020 Steel, Surf. Coat. Technol., 2019, 377, p 1–12

B. Selcuk, R. Ipek, and M.B. Karamis, A Study on Friction and Wear Behavior of Carburized, Carbonitrided and Borided AISI, 1020 and 5115 Steels, J. Mater. Process. Technol., 2003, 141, p 189–196

M. Hafizuddin, B. Abdullah, and S.K. Alias, Wear Properties of Paste Boronized 316 Stainless Steel Before and After Shot Blasting Process, Sci. Res. J., 2014, 11, p 1–10

Y. Kayali, A. Buyuksagis, and Y. Yalcin, Corrosion and Wear Behavior of Borinized AISI, 316L Stainless Steel, Met. Mater. Int., 2013, 19, p 1053–1061

E. Hernández, J.C. Velázquez, J.L. Castrejón, A. Chino, I.P. Torres, R. Carrera, J.A. Yescas, and C. Orozco, Tribological Behavior of Borided AISI, 316L Steel with Reduced Friction Coefficient and Enhanced Wear Resistance, Mater. Trans., 2019, 60, p 156–164

I. Campos, M. Ortiz, O. Bravo, M.A. Doñu, D. Bravo, C. Tapia, and M.Y. Jiménez, Formation and Kinetics of FeB/Fe2B Layers and Diffusion Zone at the Surface of AISI, 316 Borided Steels, Surf. Coat. Technol., 2010, 205, p 403–412

Metallic Materials, Instrumented Indentation Test for Hardness and Materials Parameter-Part 4: Test Method for Metallic and Non-metallic Coating 14577, Part 4, ISO, 2007

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7, p 1564–1583

Metallic Materials-Instrumented Indentation Test for Hardness and Materials Parameters-Part 1: Test method, ISO 14577-1, International Organization for Standardization, 2002

J. Anuradha, N. Dandapat, D. Mitun, K.B. Vamsi, C. Shirshendu, S. Rajnarayan, and K.M. Awadesh, Severe Wear Behaviour of Alumina Balls Sliding Against Diamond Ceramic Coatings, Bull. Mater. Sci., 2016, 39, p 573–586

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24, p 981–988

I. Campos, E. Hernández, G. Rodríguez, H. Cimenoglu, J.L. Nava, A. Meneses, and R. Carrera-Espinoza, A Study of Indentation for Mechanical Characterization of the Fe2B Layer, Surf. Coat. Technol., 2013, 232, p 173–181

I. Campos, M. Farah, N. López, G. Bermúdez, G. Rodríguez, and C. Villa Velázquez, Evaluation of the Tool Life and Fracture Toughness of Cutting Tools Boronized by the Paste Boriding Process, Appl. Surf. Sci., 2008, 254, p 2967–2974

E.J. Hernández-Ramírez, A. Guevara-Morales, U. Figueroa-López, and I. Campos-Silva, Wear Resistance of Diffusion Annealed Borided AISI, 1018 Steel, Mater. Lett., 2020, 277, p 1–8

G.A. Rodríguez, R.C. Vega, A. Meneses, H.W. Jiménez, J.A. Andraca, I.E. Campos, and M.E. Palomar, Multi-pass Scratch Test Behavior of AISI, 316L BORIDED STEEL, Surf. Coat. Technol., 2016, 307, p 491–499

C. Martini, G. Palombarini, and M. Carbucicchio, Mechanism of Thermochemical Growth of Iron Borides on Iron, J. Mater. Sci., 2004, 39, p 933–937

L. Qian, M. Li, Z. Zhou, H. Yang, and X. Shi, Comparison of Nano-indentation Hardness to Microhardness, Surf. Coat. Technol., 2005, 193, p 264–271

A. Leyland and A. Matthews, On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour, Wear, 2000, 246, p 1–11

R. Carrera, U. Figueroa, J. Martinez, I. Campos, E. Hernández, and A. Motallebzadeh, Tribological Behavior of Borided AISI, 1018 Steel under Linear Reciprocating Slinding Conditions, Wear, 2016, 362, p 1–7

D. Tabor, Hardness of Metals, Clarendon Press, Oxford, 1951

Acknowledgments

This work was supported by the Instituto Politécnico Nacional in Mexico [Grant Numbers 20200424].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fernández-Valdés, D., Meneses-Amador, A., Ocampo-Ramírez, A. et al. A Numerical–Experimental Study of Wear Resistance of FeB/Fe2B Systems. J. of Materi Eng and Perform 30, 839–849 (2021). https://doi.org/10.1007/s11665-020-05368-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05368-7