Abstract

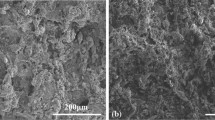

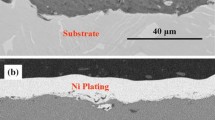

The Al-modified boronized coating on Ti-6Al-4V was successfully fabricated to protect the alloy from oxidation by the neutral salt bath method. The thickness of the Al-modified boronized coating (69.8 ± 2 μm) is 36% thicker than that of the simple-boronized coating (51.3 ± 1.5 μm). To evaluate the oxidation resistance, the high-temperature oxidation behavior was analyzed by the high-temperature oxidation experiment at 700 and 900 °C. The results show that after oxidation, the Al-modified boronized coating was mainly comprised of TiO2, Al2O3, Al3Ti, Ti3B4 and TiS phases, and the surface of the Al-modified boronized coating is smoother and denser. The thickness of the oxide layer of the Al-modified boronized coating is the minimum, which is 11 ± 0.3 μm and 13 ± 0.5 μm at 700 and 900 °C for 60 h, respectively. The average oxidation rate of the Al-modified boronized coating is − 0.003 and 0.022 mg cm−2 h−1 due to the formation of Al2O3 on the surface. Therefore, adding Al into the simple-boronized coating is beneficial for the high-temperature oxidation resistance.

Similar content being viewed by others

References

J.J. Dai, J.Y. Zhu, C.Z. Chen, and F. Weng, High Temperature Oxidation Behavior and Research Status of Modifications on Improving High Temperature Oxidation Resistance of Titanium Alloys and Titanium Aluminides: A Review, J. Alloys Compd., 2016, 685, p 784–798

J.W. Song, Y.F. Han, M.H. Fang, F.G. Hu, L.D. Ke, L.M. Lei, and W.J. Lu, Temperature Sensitivity of Mechanical Properties and Microstructure During Moderate Temperature Deformation of Selective Laser Melted Ti-6Al-4V Alloy, Mater. Charact., 2020, 165, p 110342

M.T. Tsai, Y.W. Chen, C.Y. Chao et al., Heat-Treatment Effects on Mechanical Properties and Microstructure Evolution of Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion, J. Alloys Compd., 2020, 816, p 125615

M. Carola, C. Guerra, D. Silva et al., Effect of Porosity on Mechanical and Electrochemical Properties of Ti-6Al-4V Alloy, Electrochim. Acta, 2020, 338, p 135858

L. Lan, X.Y. Jin, S. Gao, B. He, and Y.H. Rong, Microstructural Evolution and Stress State Related to Mechanical Properties of Electron Beam Melted Ti-6Al-4V Alloy Modified by Laser Shock Peening, J. Mater. Sci. Technol., 2020, 50, p 153–161

Y.T. Wang, X.G. Zeng, Y. Sheng, X. Yang, and F. Wang, Multi-Objective Parameter Identification and Optimization for Dislocation-Dynamics-Based Constitutive Modeling of Ti-6Al-4V Alloy, J. Alloys Compd., 2020, 821, p 153460

Y.S. Tian, C.Z. Chen, L.X. Chen et al., Wear and Oxidation Resistance of Composite Coatings Fabricated on Ti-6Al-4V by Laser Alloying with Nitrogen and Silicon, J. Phys. D Appl. Phys., 2005, 38, p 4217–4221

W. Zhou, Y.G. Zhao, W. Li, Q.D. Qin, B. Tian, and S.W. Hu, Al-Si Coating Fused by Al + Si Powders Formed on Ti-6Al-4V Alloy and Its Oxidation Resistance, Mater. Sci. Eng. A, 2006, 430(1–2), p 142–150

Z.P. Yao, Z.H. Jiang, F.P. Wang, and G.D. Hao, Oxidation Behavior of Ceramic Coatings on Ti-6Al-4V by Micro-Plasma Oxidation, J. Mater. Process. Technol., 2007, 190(1–3), p 117–122

D.B. Wei, P.Z. Zhang, Z.J. Yao, J.T. Zhou, X.F. Wei, and P. Zhou, Cyclic Oxidation Behavior of Plasma Surface Chromising Coating On Titanium Alloy Ti-6Al-4V, Appl. Surf. Sci., 2012, 261, p 800–806

Q. Zhou, Y. Ren, Y. Du, W.C. Han, D.P. Hua, H.M. Zhai et al., Identifying the Significance of Sn Addition on the Tribological Performance of Ti-Based Bulk Metallic Glass Composites, J. Alloys Compd., 2019, 780, p 671–679

P.V. Kiryukhantsev-Korneev, I.V. Iatsyuk, N.V. Shvindina, E.A. Levashov, and D.V. Shtansky, Comparative Investigation of Structure, Mechanical Properties, and Oxidation Resistance of Mo-Si-B and Mo-Al-Si-B Coatings, Corros. Sci., 2017, 123, p 319–327

X.F. Qiang, H.J. Li, Y.L. Zhang, Z.Z. Wang, Z.X. Ba, and X.B. Zhang, Mechanical and Oxidation Protective Properties of SiC Nanowires-Toughened SiC Coating Prepared In Situ by a CVD Process on C/C Composites, Surf. Coat. Technol., 2016, 307, p 91–98

D. Blanco, J.L. Viesca, M.T. Mallada et al., Wettability and Corrosion of [NTf2] Anion-Based Ionic Liquids on Steel and PVD (TiN, CrN, ZrN) Coatings, Surf. Coat. Technol., 2016, 302, p 13–21

J.B. Lei, C. Shi, S.F. Zhou, Z.J. Gu, and L.C. Zhang, Enhanced Corrosion and Wear Resistance Properties of Carbon Fiber Reinforced Ni-Based Composite Coating by Laser Cladding, Surf. Coat. Technol., 2018, 334, p 274–285

P.C. King, P.C. Reynoldson, A. Brownrigg, and J.M. Long, Cr(N, C) Diffusion Coating Formation on Pre-Nitrocarburised H13 Tool Steel, Surf. Coat. Technol., 2004, 179(1), p 18–26

H.R.K. Zarchig, M. Jalaly, M. Soltanieh, and H. Mehrjoo, Comparison of the Activation Energies of the Formation of Chromium Carbide Coating on Carburized and Uncarburized AISI, 1020 Steel, Steel Res. Int., 2009, 80(11), p 859–864

K. Bülent, K. Yilmaz, and M.S. Gok, Microabrasion Wear Behavior of VC and CrC Coatings Deposited by Thermoreactive Diffusion Technique, Tribol. Trans., 2014, 57(2), p 345–352

M. Aghaie-Khafri and F. Fazlalipour, Vanadium Carbide Coatings on Die Steel Deposited by the Thermo-Reactive Diffusion Technique, J. Phys. Chem. Solids, 2008, 69(10), p 2465–2470

Y.L. Zhang, H.J. Li, Z.X. Hu, J.C. Ren, and K.Z. Li, Microstructure and Oxidation Resistance of Si-Mo-B Coating for C/SiC Coated Carbon/Carbon Composites, Corros. Sci., 2013, 72, p 150–155

M. Keddama and S. Taktak, Characterization and Diffusion Model for the Titanium Boride Layers Formed on the Ti6Al4V Alloy by Plasma Paste Boriding, Appl. Surf. Sci., 2017, 339, p 229–236

N. Nedfors, S. Mrazb, J. Palisaitis et al., Influence of the Al Concentration in Ti-Al-B Coatings on Microstructure and Mechanical Properties Using Combinatorial Sputtering From a Segmented TiB2/AlB2 Target, Surf. Coat. Technol., 2019, 364, p 89–98

J. Jiang, Y.F. Shen, and X.M. Feng, Microstructures Evolution, Formation Mechanisms and Properties of Sicp/Al Composite Coatings on Ti-6Al-4V Substrate Via Mechanical Alloying Method, Surf. Interfaces, 2020, 19, p 100487

J. Yang, H. Lujun, and G. Lin, Progress on Discontinuously Reinforced Titanium Matrix Composites, J. Alloys Compd., 2018, 767, p 1196–1215

Q. Wang, W.Y. Wu, M.Y. Jiang et al., Improved Oxidation Performance of TiAl Alloy by a Novel Al-Si Composite Coating, Surf. Coat. Technol., 2020, 38, p 125126

S.S. Yang, Y.Q. Wang, M.H. Chen, L.L. Yang et al., Oxidation Behavior of Al/Y Co-Modified Nanocrystalline Coatings with Different Al Content on a Nickel-Based Single-Crystal Superalloy, Corros. Sci., 2020, 170, p 108700

S. Aich and K.S.R. Chandran, TiB Whisker Coating on Titanium Surfaces by Solid-State Diffusion: Synthesis, Microstructure, and Mechanical Properties, Metall. Mater. Trans. A, 2002, 33(11), p 3489–3498

X.J. Xu, Z. Jiang, M.V. Tabie, T.Q. Niu, Q. Mao et al., Effect of Surface Boroaluminizing on Thermal Corrosion Behavior of TC4(Ti-6AL-4V) Titanium Alloy, Mater. Res. Express, 2019, 6, p 096582

K. Alaeddine and B. Khedidja, Electrochemical Boriding of Titanium Alloy Ti-6Al-4V, J. Mater. Res. Technol., 2019, 8(6), p 6407–6512

D.J. Wang, H. Li, and W. Zheng, Oxidation Behaviors of TA15 Titanium Alloy and TiBw Reinforced TA15 Matrix Composites Prepared by Spark Plasma Sintering, J. Mater. Sci. Technol., 2020, 37, p 46–54

H. Riedl, E. Aschauer, C.M. Koller, P. Polcik, M. Arndt, and P.H. Mayrhofer, Ti-Al-N/Mo-Si-B Multilayers: An Architectural Arrangement for High Temperature Oxidation Resistant Hard Coatings, Surf. Coat. Technol., 2017, 328, p 80–88

E.L. Zhang, G. Zeng, and S.Y. Zeng, Effect of In Situ TiB Short Fibre on Oxidation Behavior of Ti-6Al-1.2B Alloy, Scr. Mater., 2002, 46(11), p 811–816

Q.Y. Hou, M.F. Li, W. Shao, and C.G. Zhou, Oxidation and Interdiffusion Behavior of Mo-Si-B Coating on Nb-Si Based Alloy Prepared by Spark Plasma Sintering, Corros. Sci., 2020, 169, p 108638

W.D. Tang, S.T. Yang, and X.X. Xue, Effect of B2O3 Addition on Oxidation Induration and Reduction Swelling Behavior of Chromium-Bearing Vanadium Titanomagnetite Pellets with Simulated Coke Oven Gas, Trans. Nonferrous Met. Soc. China, 2019, 29(7), p 1549–1559

V.A.C. Haanappel, H. Clemens, and M.F. Stroosnijder, The High Temperature Oxidation Behaviour of High and Low Alloyed TiAl-Based Intermetallics, Intermetallics, 2002, 10(3), p 293–305

L. Chen, J. Paulitsch, Y. Du et al., Thermal Stability and Oxidation Resistance of Ti-Al-N Coatings, Surf. Coat. Technol., 2012, 206(11–12), p 2954–2960

Acknowledgment

This work is supported by Key Projects of Equipment Pre-research Foundation of the Ministry of Equipment Development of the Central Military Commission of China (614092 2010201).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Xu, X., Xiao, Y. et al. High-Temperature Oxidation Behavior of Al-Modified Boronized Coating Prepared on Ti-6Al-4V by Thermal Diffusion. J. of Materi Eng and Perform 29, 6503–6512 (2020). https://doi.org/10.1007/s11665-020-05170-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05170-5